Volatile stamping oil

A stamping oil, volatile technology, applied in the field of stamping oil, can solve problems such as mold expansion and softening, product dimensional accuracy decline, strain, etc., to achieve the effect of meeting modern environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

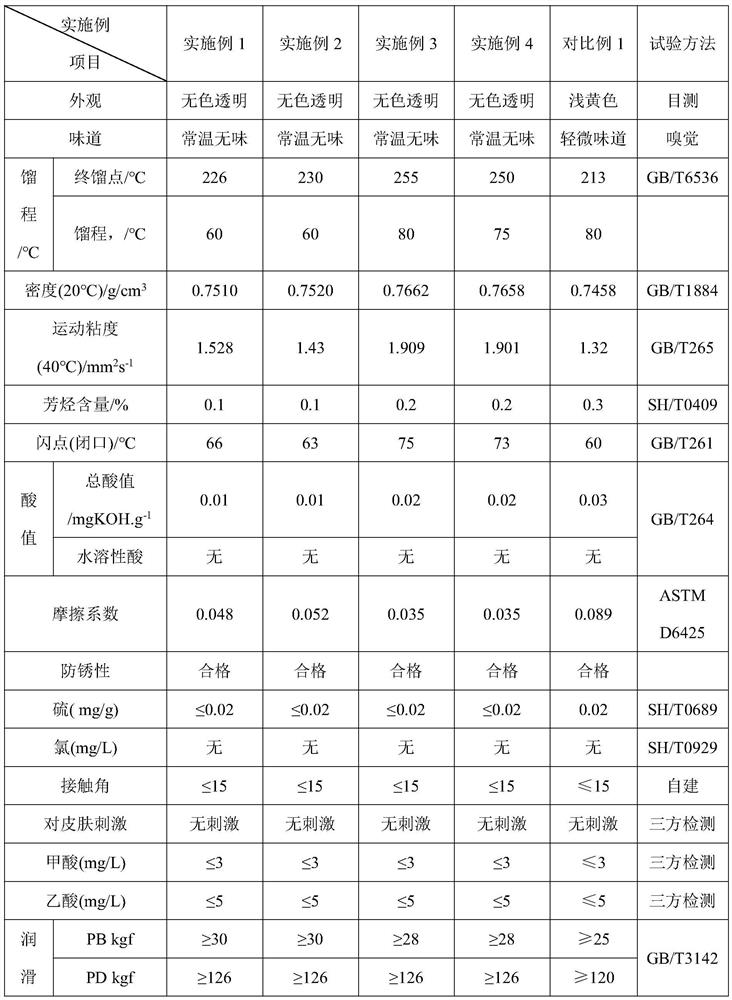

Examples

Embodiment 1

[0020] A volatile stamping oil, which comprises the following components in mass percentage: 98.2% of base oil, 0.4% of extreme pressure additive, 0.4% of hydrophilic additive, 0.6% of friction coefficient improver and 0.2% of nanometer additive.

[0021] The base oil is isoparaffin base oil, the extreme pressure additive is KLG-3, the hydrophilic additive is stearic acid, the friction coefficient modifier is molybdenum carbamate, and the nano additive is nano titanium. Also added graphene lubricant additive 0.2%.

Embodiment 2

[0023] A volatile stamping oil, which comprises the following components in mass percentage: 99% of base oil, 0.3% of extreme pressure additive, 0.2% of hydrophilic additive, 0.3% of friction coefficient improver and 0.1% of nanometer additive.

[0024] The base oil is isoparaffin base oil, the extreme pressure additive is KLG-3, the hydrophilic additive is stearic acid, the friction coefficient modifier is molybdenum carbamate, and the nano additive is nano copper. Also added graphene lubricant additive 0.1%.

Embodiment 3

[0026] A volatile stamping oil, which comprises the following components in mass percentage: 98.5% of base oil, 0.2% of extreme pressure additive, 0.4% of hydrophilic additive, 0.6% of friction coefficient improver and 0.2% of nanometer additive.

[0027] The base oil is isoparaffin base oil, the extreme pressure additive is KLG-3, the hydrophilic additive is stearic acid, the friction coefficient modifier is molybdenum carbamate, the nano additive is nano tin, and 0.1% graphene lubricating additive is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com