Wall decoration coating as well as preparation method and application thereof

A wall decoration and coating technology, applied in cement coatings, coatings and other directions, can solve the problems of yellowing of wall decoration coatings, short service life, poor environmental protection performance, etc., and achieve low comprehensive cost, long service life, and construction performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A wall decoration paint (beautiful wall treasure), its raw materials include the following components in parts by mass: 65 parts of superfine calcium carbonate, 25 parts of slag micropowder, 0.5 part of magnesium aluminum silicate, 0.2 part of redispersible latex powder 10 parts of white cement, 0.05 parts of polycarboxylate superplasticizer, 0.2 parts of methyl cellulose, 0.1 part of waterproof powder, and 0.05 parts of anti-alkali agent.

[0031] The preparation method of above-mentioned wall decoration paint, comprises the steps:

[0032] (1) Prepare raw materials according to the components contained in the above-mentioned wall decoration paint and their mass proportions;

[0033] (2) Put the obtained raw material powders into a dry powder mixer in turn, mix and stir evenly for 20 minutes, and then prepare the wall decoration paint.

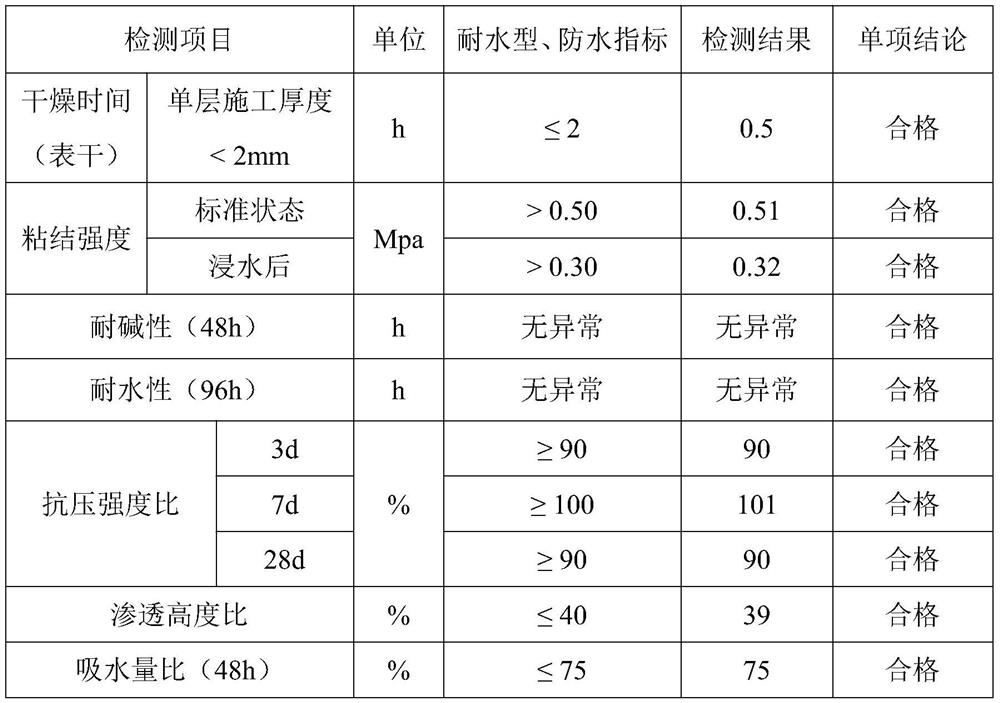

[0034] The color of this embodiment can be customized upon request. After the wall is leveled, mix the wall decoration paint with w...

Embodiment 2

[0039]A wall decoration paint (beautiful wall treasure), its raw materials include the following components in parts by mass: 60 parts of superfine calcium carbonate, 25 parts of slag micropowder, 0.8 part of magnesium aluminum silicate, 0.25 parts of redispersible latex powder 15 parts of white cement, 0.1 part of polycarboxylate superplasticizer, 0.25 part of methyl cellulose, 0.2 part of waterproof powder, and 0.1 part of anti-alkali agent.

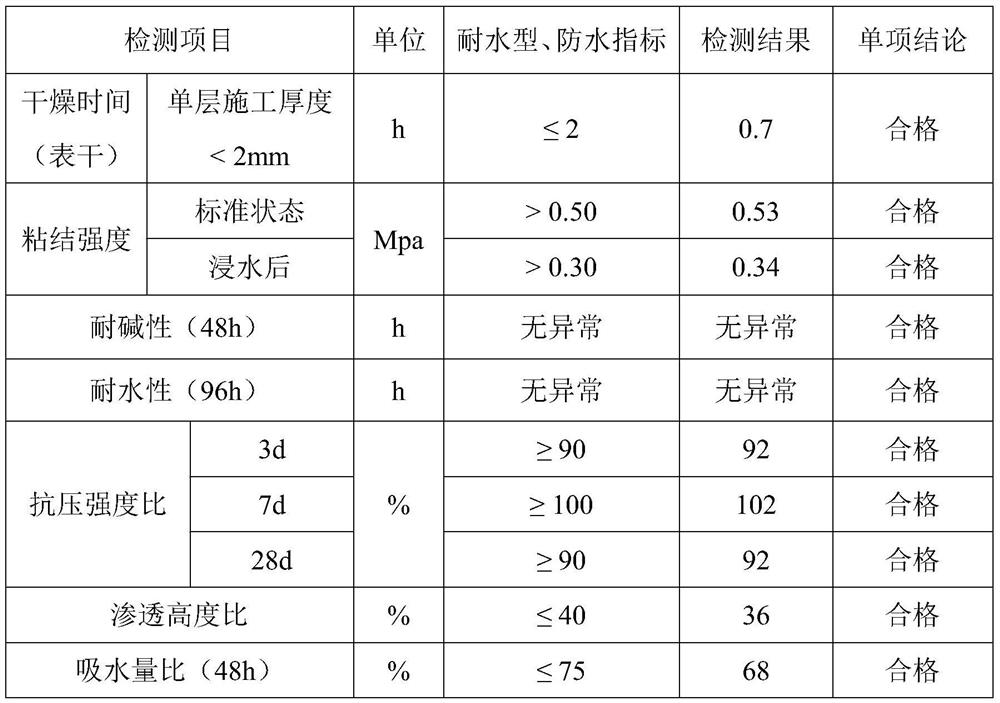

[0040] The preparation method of the above-mentioned wall decoration paint is the same as that of Example 1, and the color can be customized according to requirements. After the wall is leveled, mix the wall decoration paint with water and stir evenly. After standing for 5 minutes, apply and scrape on the wall surface to replace the putty wall surface and latex paint. The test results of the wall decoration paint of this embodiment are shown in Table 2.

[0041] Table 2: Various test results of the wall decoration paint of embodiment ...

Embodiment 3

[0045] A wall decoration paint (beautiful wall treasure), its raw materials include the following components in parts by mass: 60 parts of superfine calcium carbonate, 20 parts of slag micropowder, 1 part of magnesium aluminum silicate, 0.3 parts of redispersible latex powder 20 parts, 20 parts of white cement, 0.12 parts of water reducer, 0.35 parts of methyl cellulose, 0.3 parts of waterproof powder, 0.15 parts of anti-alkali agent.

[0046] The preparation method of the above-mentioned wall decoration paint is the same as that of Example 1, and the color can be customized according to requirements. After the wall is leveled, mix the wall decoration paint with water and stir evenly. After standing for 5 minutes, apply and scrape on the wall surface to replace the putty wall surface and latex paint. The test results of the wall decoration paint of this embodiment are shown in Table 3.

[0047] Table 3: Various test results of the wall decoration paint of embodiment 3

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com