Preparation method of negative electrode of lithium ion battery

A lithium-ion battery and negative electrode technology, which is applied in electrode manufacturing, battery electrodes, negative electrodes, etc., can solve problems such as affecting the cycle life of power lithium-ion batteries, falling off of active material layers, and producing lithium metal dendrites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

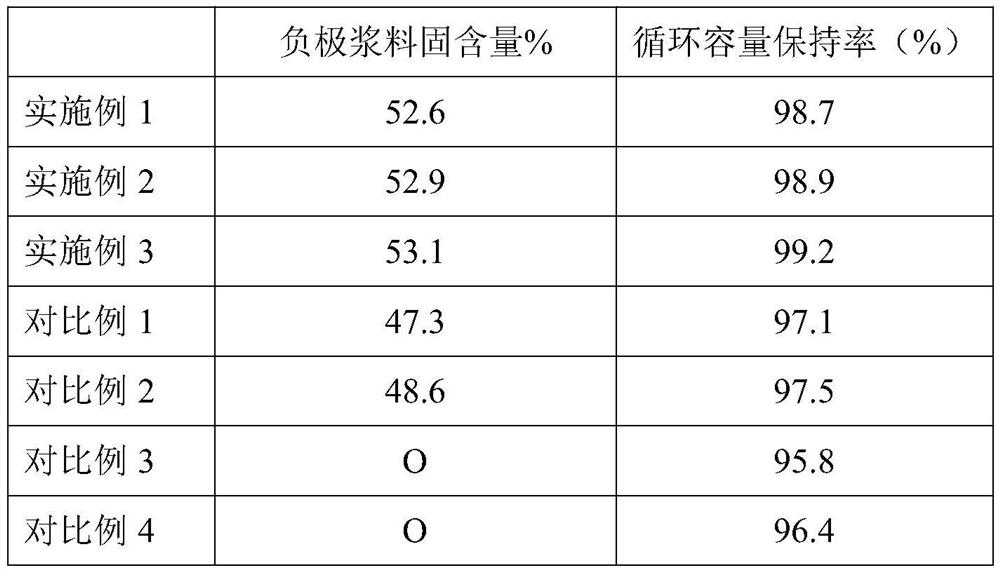

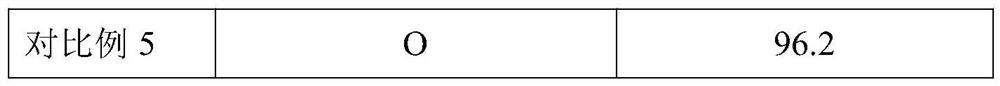

Examples

Embodiment 1

[0025] 1) provide the first graphite material, the second graphite material and the third graphite material, the average particle diameter D1 of the first graphite material is 2.20 microns, the average particle diameter D2=1.42*D1=3.12 of the second graphite material micron; the average particle diameter D3=0.56*D1=1.23 micron of the third graphite material;

[0026] 2) Mix the first graphite material, the second graphite material and the third graphite material according to a predetermined mass ratio, wherein the first graphite material: the second graphite material: the third graphite material=1:(0.56*1.42):(0.82* 0.56) = 1:0.80:0.46;

[0027] 3) Add binder, graphite material and conductive agent to deionized water in order to obtain negative electrode slurry; wherein mass ratio, graphite material: binder: conductive agent=100:4.2:3; the binder For SBR, the conductive agent is selected from acetylene black;

[0028] 4) Coating the negative electrode slurry on the negative ...

Embodiment 2

[0032] 1) provide the first graphite material, the second graphite material and the third graphite material, the average particle diameter D1 of the first graphite material is 2.4 microns, the average particle diameter D2=1.45*D1=3.48 of the second graphite material micron; the average particle diameter D3=0.58*D1=1.39 micron of the third graphite material;

[0033] 2) Mix the first graphite material, the second graphite material and the third graphite material according to a predetermined mass ratio, wherein the first graphite material: the second graphite material: the third graphite material=1:(0.56*1.45):(0.82* 0.58) = 1:0.81:0.48;

[0034] 3) Add binder, graphite material and conductive agent to deionized water in order to obtain negative electrode slurry; wherein mass ratio, graphite material: binder: conductive agent=100:4.2:3-5; The binding agent is SBR, and the conductive agent is selected from acetylene black;

[0035] 4) Coating the negative electrode slurry on th...

Embodiment 3

[0039] 1) provide the first graphite material, the second graphite material and the third graphite material, the average particle diameter D1 of the first graphite material is 2.3 microns, the average particle diameter D2=1.44*D1=3.31 of the second graphite material Micron; the average particle diameter D3=0.57*D1=1.31 micron of the third graphite material;

[0040] 2) Mix the first graphite material, the second graphite material and the third graphite material according to a predetermined mass ratio, wherein the first graphite material: the second graphite material: the third graphite material=1:(0.56*1.44):(0.82* 0.57) = 1:0.81:0.47;

[0041] 3) Add binder, graphite material and conductive agent to deionized water in order to obtain negative electrode slurry; wherein mass ratio, graphite material: binder: conductive agent=100:4.2:4; the binder For SBR, the conductive agent is selected from acetylene black;

[0042] 4) Coating the negative electrode slurry on the negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com