Silicone sealant with anti-bulging performance and preparation method thereof

A silicone sealant, performance technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of little glue seam bulging, insufficient curing depth and curing strength of silicone sealants, Low efficiency and other problems, to achieve the effect of solving the problem of easy shrinkage and bulging of the glue seam and excellent anti-bulging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

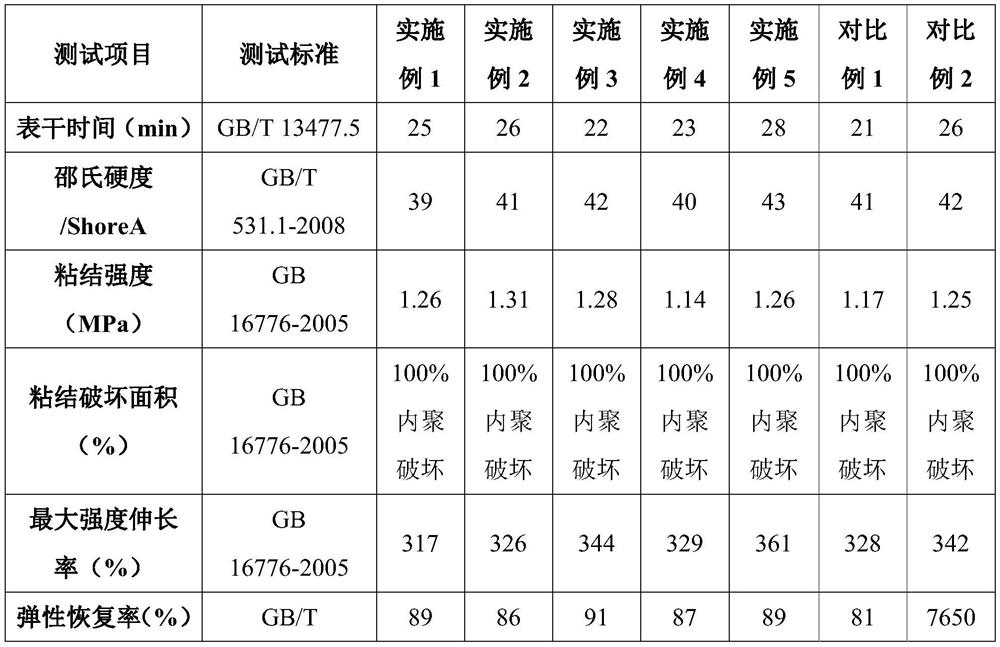

Embodiment 1

[0033] A kind of silicone sealant with anti-bulging performance, its preparation method comprises the following steps:

[0034] 1) Add 100 parts by mass of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 500000cps and 40 parts by mass of nano-calcium carbonate into the kneader, and dehydrate for 180min at a temperature of 100°C and a vacuum of -0.08MPa. get base material;

[0035] 2) Mix the silane coupling agent KH-550 and the silane coupling agent KH-560 according to the molar ratio of 1:2, and stir at 105°C for 4 hours to obtain the aminosilane-epoxysilane copolymer;

[0036] 3) Add the base material of step 1) into a planetary mixer, then add 2 parts by mass of tetrabutanoximinosilane, 18 parts by mass of methyltributanoximinosilane, 10 parts by mass of aminosilane-cyclosilane in step 2). Oxysilane copolymer, 2 parts by mass of silane coupling agent KH-550 and 0.5 parts by mass of dibutyltin dilaurate, stirred and dispersed for 40 minutes under a vacuum of -0.1MPa ...

Embodiment 2

[0038] A kind of silicone sealant with anti-bulging performance, its preparation method comprises the following steps:

[0039] 1) Add 100 parts by mass of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 50000cps and 100 parts by mass of nano-calcium carbonate into the kneader, and dehydrate for 180min at a temperature of 110°C and a vacuum of -0.08MPa. get base material;

[0040] 2) Mix the silane coupling agent KH-540 and the silane coupling agent KH-560 according to the molar ratio of 1:2, and stir at 105°C for 4 hours to obtain the aminosilane-epoxysilane copolymer;

[0041] 3) Add the base material of step 1) into the planetary mixer, then add 10 parts by mass of tetrabutanoximinosilane, 25 parts by mass of methyltributanoximinosilane, and 5 parts by mass of aminosilane-cyclosilane in step 2). Oxysilane copolymer, 5 parts by mass of silane coupling agent KH-550 and 0.1 part by mass of dibutyltin diacetate, stirred and dispersed for 40 minutes under a vacuum of -0....

Embodiment 3

[0043] A kind of silicone sealant with anti-bulging performance, its preparation method comprises the following steps:

[0044] 1) Add 100 parts by mass of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 50,000cps, 10 parts by mass of fumed silica and 10 parts by mass of heavy calcium into the kneader, at a temperature of 90°C and a vacuum of - Dehydration under the condition of 0.08MPa for 180min to obtain the base material;

[0045] 2) Mix the silane coupling agent KH-550 and the silane coupling agent KH-560 according to the molar ratio of 1:2, and stir at 105°C for 4 hours to obtain the aminosilane-epoxysilane copolymer A;

[0046] 3) Mix the silane coupling agent KH-792 and the silane coupling agent KH-560 according to the molar ratio of 1:2, and stir at 105°C for 4 hours to obtain the aminosilane-epoxysilane copolymer B;

[0047]4) Add the base material of step 1) into a planetary mixer, then add 5 parts by mass of tetrabutanoximinosilane, 25 parts by mass of meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com