Metal machining equipment for adjusting bending angle and bending method

A metal processing and bending angle technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as poor fixation, inability to adjust the bending angle, increase the difficulty of workers' work, etc., and achieve increased stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

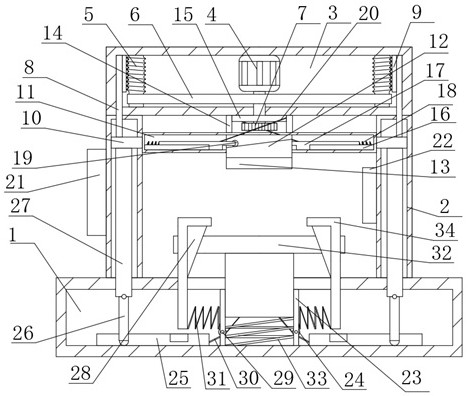

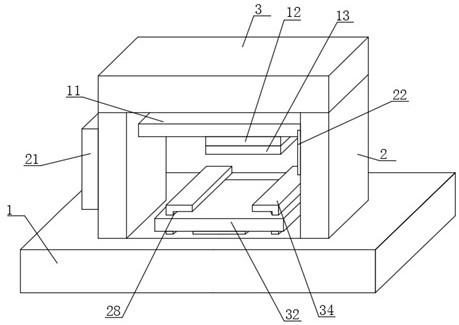

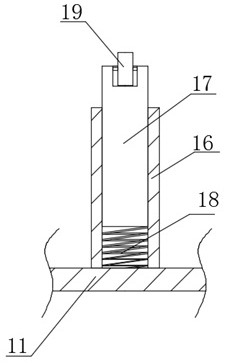

[0036] refer to Figure 1-7 In this embodiment, a metal processing equipment for adjusting the bending angle is proposed, which includes a base 1, and the base 1 has a hollow structure, and the top of the base 1 is symmetrically fixedly connected with a hollow support plate 2, and the support plate 2 There are two, the tops of the two support plates 2 are provided with the same control box 3, the top inner wall of the control box 3 is fixedly installed with a motor 4, and the output shaft of the motor 4 extends to the outside of the control box 3 and is fixedly connected with a gear 7, The left side of the support plate 2 on the left side is provided with a central controller 21, the left side of the support plate 2 on the right side is provided with an observation camera 22, the support plate 2 is slidably connected with a slide plate 10, and the slide plate 10 is two One, the sides of the two sliding plates 10 close to each other extend to the outside of the support plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com