Layered porous polyelectrolyte coating and preparation method thereof

A polyelectrolyte and coating technology, applied in the field of layered porous polyelectrolyte coating and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

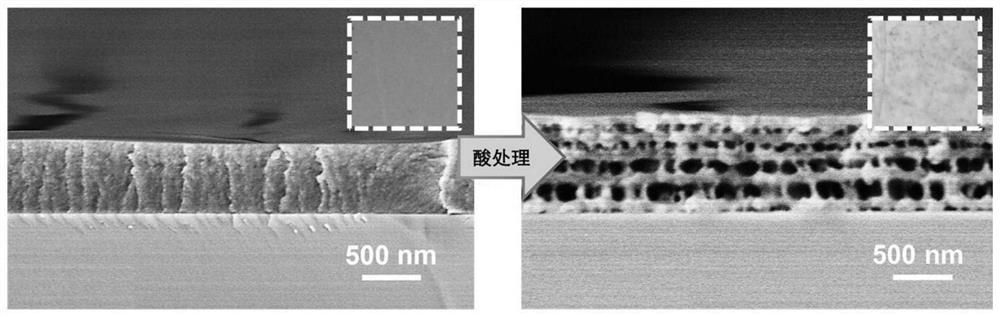

[0045] The scanning electron microscope picture of embodiment 1 is as figure 1 shown by figure 1 It can be seen that the flat and dense polypropyleneimine and modified polyacrylic acid coatings before acid treatment on the left will form the microporous structure in the picture on the right after layered crosslinking and acid treatment, and the microporous structure Distributed in layers. This is mainly due to the strong movement ability of the molecular chains in the uncrosslinked region, which is prone to microphase separation in acid solution or alkaline solution to form a pore structure, while the movement ability of the molecular chains of the crosslinked layer is limited, maintaining a flat and compact state, by This enables the preparation of layered porosity.

Embodiment 2

[0047] (1) Dissolve heparin and 4-aminobenzophenone in water, under the catalysis of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide and N-hydroxysulfosuccinimide After reacting for 48 hours, a modified heparin with a grafting rate of 5% was obtained.

[0048] (2) Soak the cleaned silicon wafer (2cm×2cm×1mm) in polydiallyldimethylamine aqueous solution (1mg / mL, pH 10.0) for 30 minutes, take it out, wash it three times with ultra-clean water Blow dry with nitrogen; then soak it in modified heparin aqueous solution (5mg / mL, pH 4.0) for 30 minutes, take it out, wash it with ultra-clean water three times, and then blow dry with nitrogen to complete the coating of one deposition cycle. Layer preparation; the above steps were repeated to complete 20 deposition cycles of coating preparation on the substrate.

[0049] (3) placing the coating prepared in step (2) in a humid and dark environment (100% relative humidity) for 36 hours to obtain a smooth and dense polydiallyldimethylamine / m...

Embodiment 3

[0054] (1) Dissolve polymethacrylic acid and 4-azidoaniline in water at a molar ratio of 30:1, and in 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide and N-hydroxysulfur Under the catalysis of substituted succinimide, react for 72 hours to obtain modified polymethacrylic acid.

[0055] (2) Soak the cleaned glass sheet (2cm×2cm×1mm) in polyethyleneimine aqueous solution (3mg / mL, pH 9.0) for 20 minutes, take it out, wash it with ultra-clean water three times, and blow it dry with nitrogen; Then put it into the modified polymethacrylic acid aqueous solution (3mg / mL, pH 3.0) and soak it for 20 minutes, take it out, wash it with ultra-clean water three times, and blow it dry with nitrogen gas, so as to complete the coating of one deposition cycle. Preparation; repeat the above steps to complete 8 deposition cycles of coating preparation on the substrate.

[0056] (3) placing the coating prepared in step (2) in a humid dark environment (100% relative humidity) for 48 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com