Bromine trifluoride and load gas batching method and device

A technology of bromine trifluoride and loading, which is applied in the direction of chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problems affecting the economy and safety of equipment operation, and the decline of equipment operation performance, and achieve the flow rate of batching gas and Precise ratio, simple method and device, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

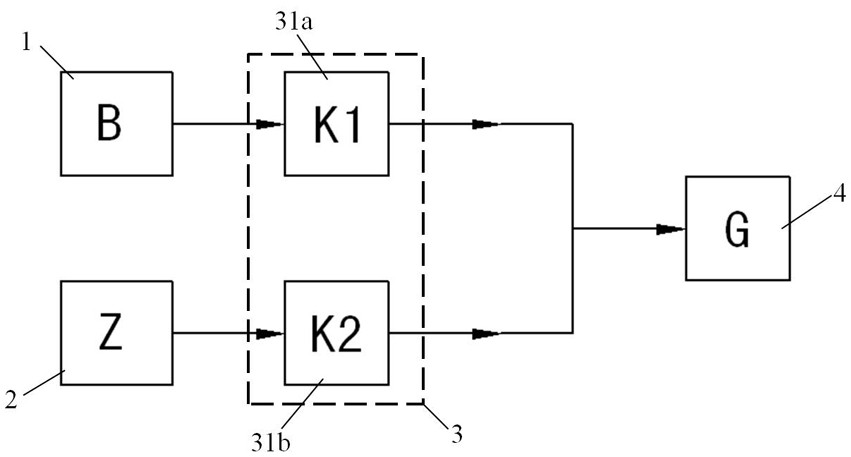

[0036] Such as figure 1 As shown, a bromine trifluoride and load gas dosing device includes a bromine trifluoride supply container 1 and a load gas supply container 2, both of which communicate with radioactive equipment 4 through pipelines and a control mechanism 3. The control mechanism 3 includes a bromine trifluoride flow metering control device 31a arranged on the pipeline between the bromine trifluoride supply container 1 and the radioactive equipment 4, and a bromine trifluoride flow metering control device 31a arranged between the load gas supply container 2 and the radioactive equipment 4 Load gas flow metering controller device 31b on the pipeline.

[0037] The bromine trifluoride flow metering control device 31a is a critical flow nozzle; the load gas flow metering controller device 31b is a thermal gas mass flow controller.

[0038] The carrier gas in the carrier gas supply container 2 is iodine heptafluoride.

Embodiment 2

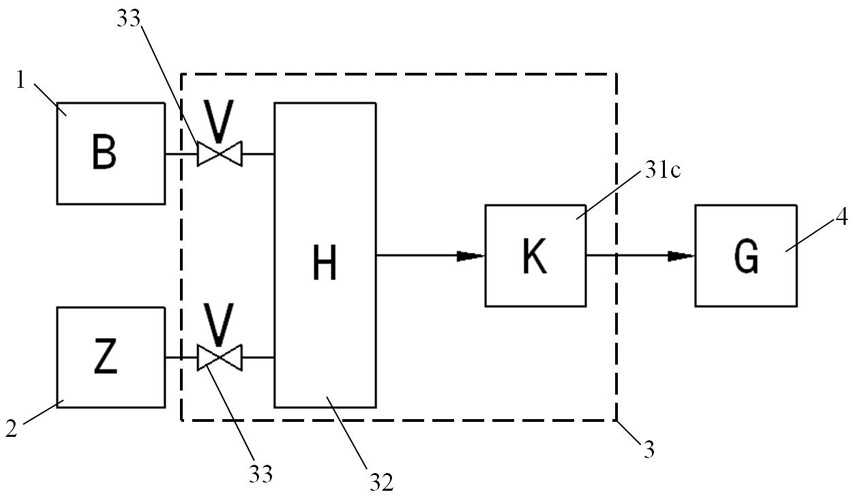

[0040] Such as figure 2 As shown, a bromine trifluoride and load gas dosing device is characterized in that: it includes a bromine trifluoride supply container 1 and a load gas supply container 2, both of which communicate with radioactive equipment 4 through pipelines and a control mechanism 3 .

[0041] The control mechanism 3 includes a mixing ingredient container 32 communicated with the radioactive equipment 4 through a mixed gas flow controller device 31c, the bromine trifluoride supply container 1 and the load gas supply container 2 are respectively communicated with the mixing ingredient container 32, and communicated with each other. Valves 33 are arranged on the pipelines.

[0042] The mixed gas flow metering controller device 31c uses a regulating valve and a critical flow nozzle connected in series in the pipeline.

[0043] The carrier gas in the carrier gas supply container 2 is iodine heptafluoride.

Embodiment 3

[0045] Based on embodiment 1 device, a kind of bromine trifluoride and load gas batching method comprise the following steps:

[0046] The bromine trifluoride gas produced by gasification from the bromine trifluoride supply container 1 flows through the critical flow nozzle, and the nozzle is used to control and measure the bromine trifluoride gas flow rate. The bromine trifluoride molar flow rate is X=kP, k P is a constant related to the shape and diameter of the nozzle and the physical properties of bromine trifluoride, which can be given by calculation or actual calibration, and P is the pressure in front of the nozzle. If the flow coefficient k of the nozzle for bromine trifluoride gas is 0.0002 mol / (h·Pa), and the pressure in front of the nozzle is 500 Pa, then the flow rate of bromine trifluoride gas flowing through the nozzle can be calculated as 0.1 mol / h.

[0047] Gasification of iodine heptafluoride gas from the load gas iodine heptafluoride supply container flows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com