High-voltage cable perforating equipment

A cable and high-voltage technology, applied in the field of high-voltage cable piercing equipment, can solve the problems of increased sliding resistance in the pipe, time-consuming and labor-intensive cable piercing, and affecting the piercing efficiency, so as to reduce improper operation, save manpower, and improve the piercing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

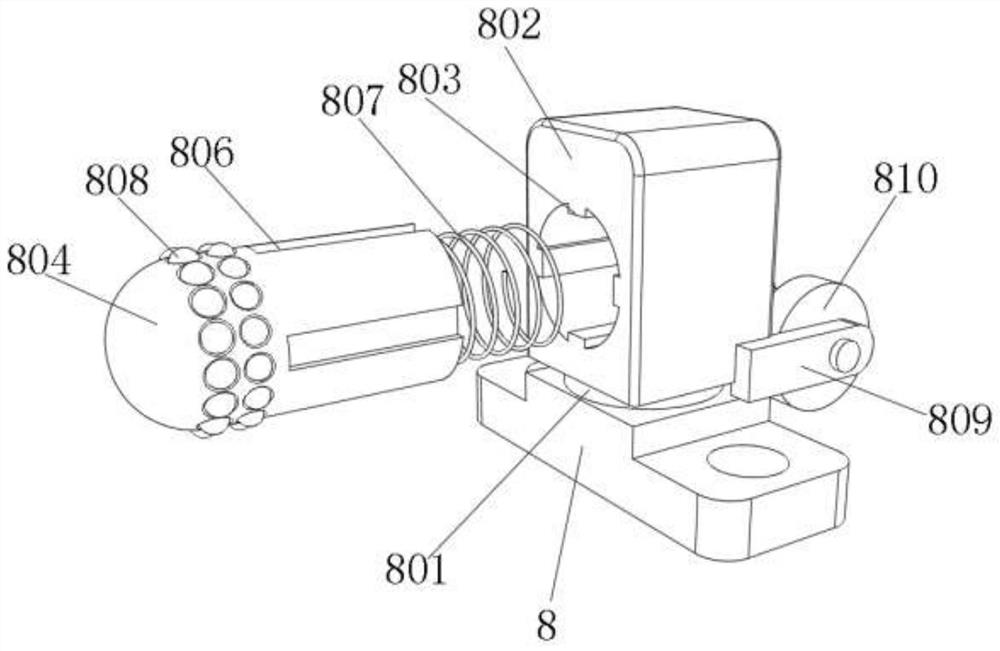

[0032] refer to Figure 1-Figure 5 , a high-voltage cable piercing equipment, including a bottom plate 1, a lifting mechanism fixed on one side of the bottom plate 1 by bolts, and a take-up reel 4 is inserted into the inside of the lifting mechanism, a pushing mechanism is arranged on one side of the bottom plate 1, and the top of the bottom plate 1 is fixed by bolts The base 8 is fixed, and the top of the base 8 is rotatably connected to a rotating shaft 801, and the top of the rotating shaft 801 is fixed with a block 802 by bolts, and one side of the block 802 is provided with a card hole, and the inner wall of the card hole is integrally formed with a protrusion 803 , the inner wall of the clamping hole is inserted with a perforated sleeve 804, and one side of the perforated sleeve 804 is provided with an insertion slot 806, and the insertion slot 806 is engaged with the protrusion 803, and one end of the perforated sleeve 804 is fixed with a first spring 807 by a bolt, The...

Embodiment 2

[0036] refer to Figure 6 , a high-voltage cable punching device, one end of the bottom plate 1 is fixed with two support frames 11 by bolts, and one side of the two support frames 11 is fixed with a fixed shaft 1101 by bolts, and the other end of the fixed shaft 1101 is plugged with the same A guide tube 1102, one end of the guide tube 1102 is fixed with a connecting snap ring 1103 by a bolt, and the other end of the connecting snap ring 1103 is fixed with a plug-in hose 1104 by a bolt, the inner wall of the plug-in hose 1104 is provided with a third spring 1105, and the guide tube 1102, the joint use of the connecting hose 1104 and the third spring 1105 can prevent the edge of the pipe from slipping on the surface of the cable when the hole is perforated, reducing the damage to the cable, and can also greatly reduce the impact on the cable caused by the edge of the pipe. The friction force improves the perforation efficiency.

[0037] The working principle of this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com