Upconversion photon anti-counterfeiting bar code based on dual-wavelength response and construction method and application thereof

A construction method and bar code technology, which are applied to record carriers, instruments, and computer parts used in machines, can solve the problems of inability to meet large data storage requirements, low anti-counterfeiting technology, and small coding space, so as to improve coding capabilities and Anti-counterfeiting level, flexible adjustment, the effect of high encryption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the present invention, the preparation method of the rare earth-doped up-conversion luminescent material preferably includes the following steps:

[0037] The rare earth oxide, BaCO 3 Grinding and mixing with ZnO, and sintering the resulting mixed material to obtain a rare earth doped up-conversion luminescent material; the rare earth oxide includes Yb 2 o 3 , also includes Er 2 o3 、Pr 2 o 3 、Tm 2 o 3 or Ho 2 o 3 .

[0038] In the present invention, the rare earth oxide, BaCO 3 The molar ratio to ZnO is preferably 4:5:4. In the present invention, the rare earth oxide includes Yb 2 o 3 , also includes Er 2 o 3 、Pr 2 o 3 、Tm 2 o 3 or Ho 2 o 3 ; the Yb 2 o 3 with Er 2 o 3 (Pr 2 o 3 、Tm 2 o 3 or Ho 2 o 3 ) molar ratio to meet the above-mentioned doping concentration range.

[0039] In the present invention, the rare earth oxide, BaCO 3 The process of grinding and mixing with ZnO is preferably carried out in an agate mortar, and the grindin...

Embodiment 1

[0053] Rare earth oxide (Yb 2 o 3 and Er 2 o 3 ), 6mmol BaCO 3 and 4.8 mmol ZnO were ground in an agate mortar for 40 min, and the resulting mixture was placed in an alumina crucible, and sintered in air at 1200 ° C in a muffle furnace for 4 h; after sintering, the muffle furnace was naturally cooled to room temperature, After fully grinding, the rare earth doped up-conversion luminescent material is obtained, wherein the rare earth ion Y 3+ 、Er 3+ and Yb 3+ The total molar percentage is 100mol%, Yb 3+ The ion doping concentration is 1mol%, Er 3+ The ion doping concentration is 3mol%;

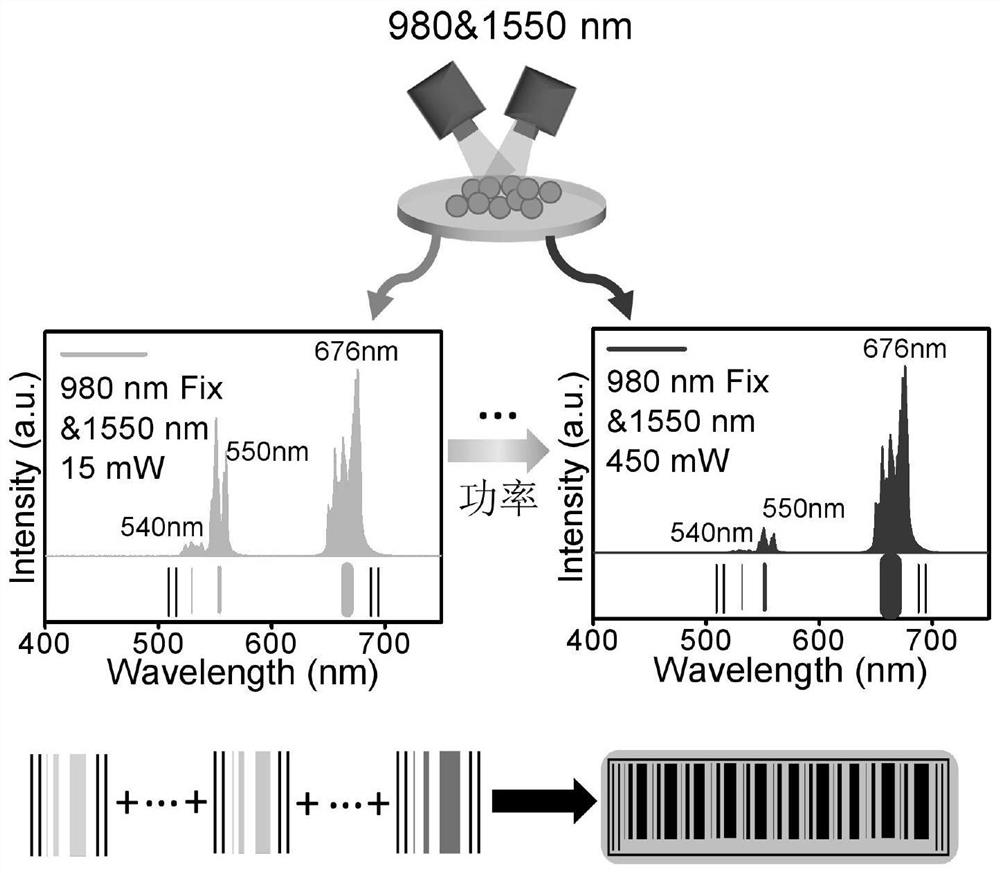

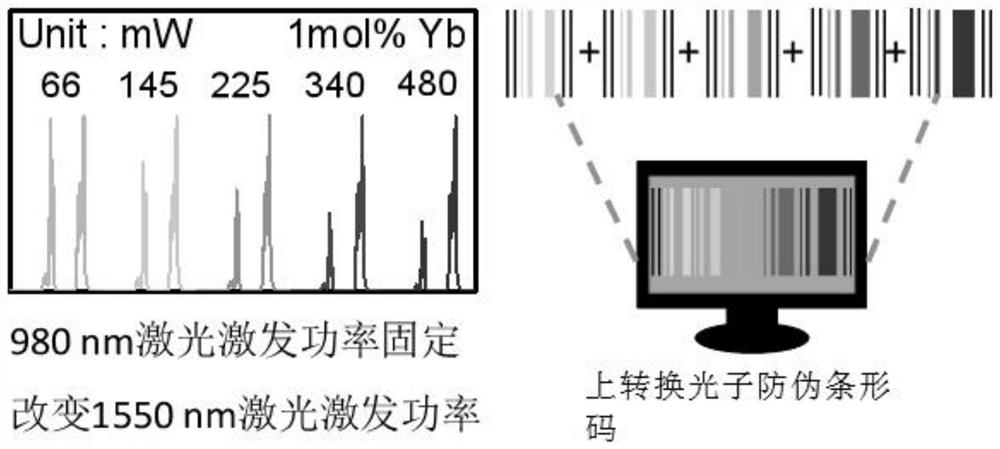

[0054] Select 980nm and 1550nm wavelength lasers to jointly excite the rare earth-doped up-conversion luminescent material, wherein the 980nm laser excitation power is fixed at 720mW, the 1550nm laser excitation power is changed, and five groups of 1550nm laser excitation powers are selected, which are 66mW, 145mW, and 225mW respectively , 340mW and 480mW to obtain 5 groups of differen...

Embodiment 2

[0062] Rare earth oxide (Yb 2 o 3 and Er 2 o 3 ), 6mmol BaCO 3 and 4.8 mmol ZnO were ground in an agate mortar for 40 min, and the resulting mixture was placed in an alumina crucible, and sintered in air at 1200 ° C in a muffle furnace for 4 h; after sintering, the muffle furnace was naturally cooled to room temperature, After fully grinding, the rare earth doped up-conversion luminescent material is obtained, wherein the rare earth ion Y 3+ 、Er 3+ and Yb 3+ The total molar percentage is 100mol%, Yb3+ The ion doping concentration is 1mol%, Er 3+ The ion doping concentration is 3mol%;

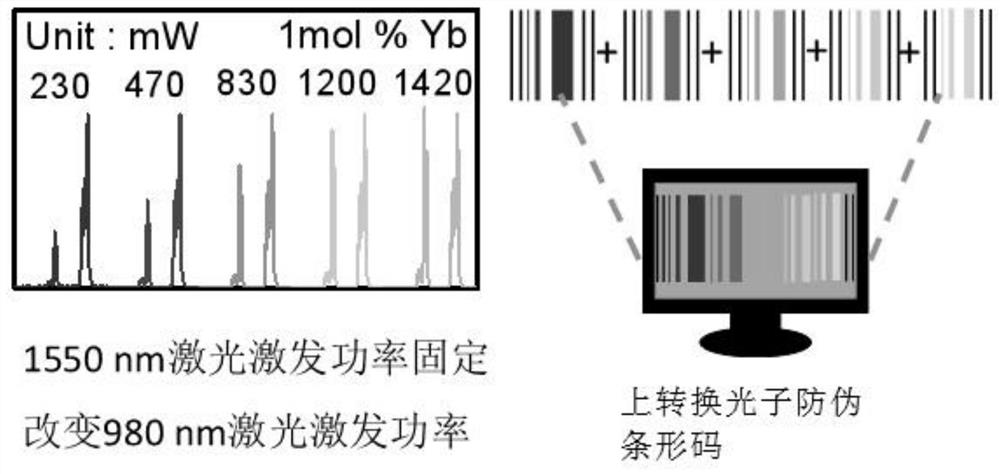

[0063] Select 980nm and 1550nm wavelength lasers to jointly excite the rare earth-doped up-conversion luminescent material, wherein the 1550nm laser excitation power is fixed at 380mW, the 980nm laser excitation power is changed, and five groups of 980nm laser excitation powers are selected, which are 230mW, 470mW, and 830mW respectively , 1200mW and 1420mW to obtain 5 groups of differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com