A skin-core structural fiber with both infrared and radar stealth and its preparation method and application

A radar stealth, skin-core structure technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve the problems of complex preparation process and single final product forming method, achieve convenient use, good electromagnetic wave absorption performance, compensation single function effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

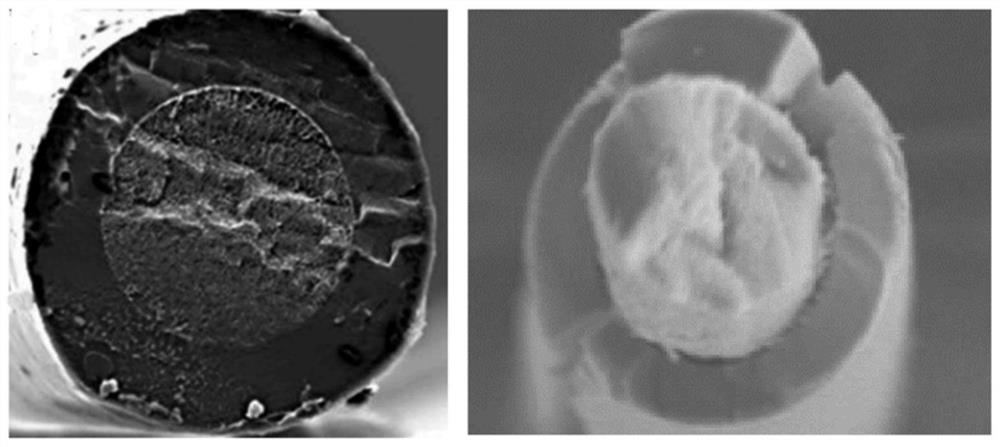

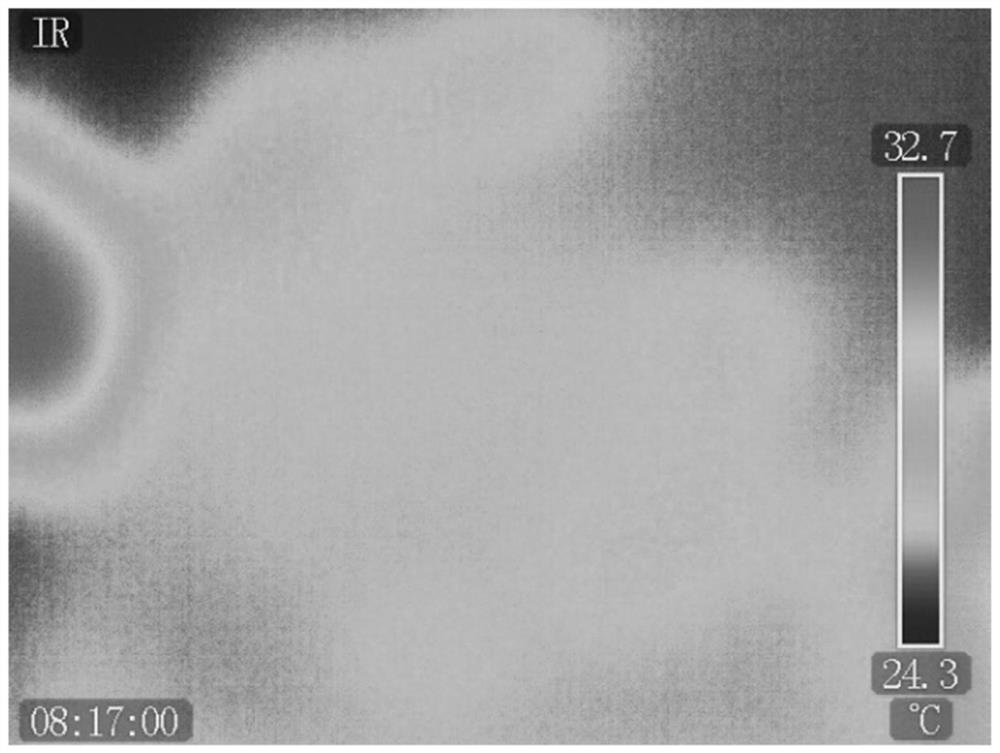

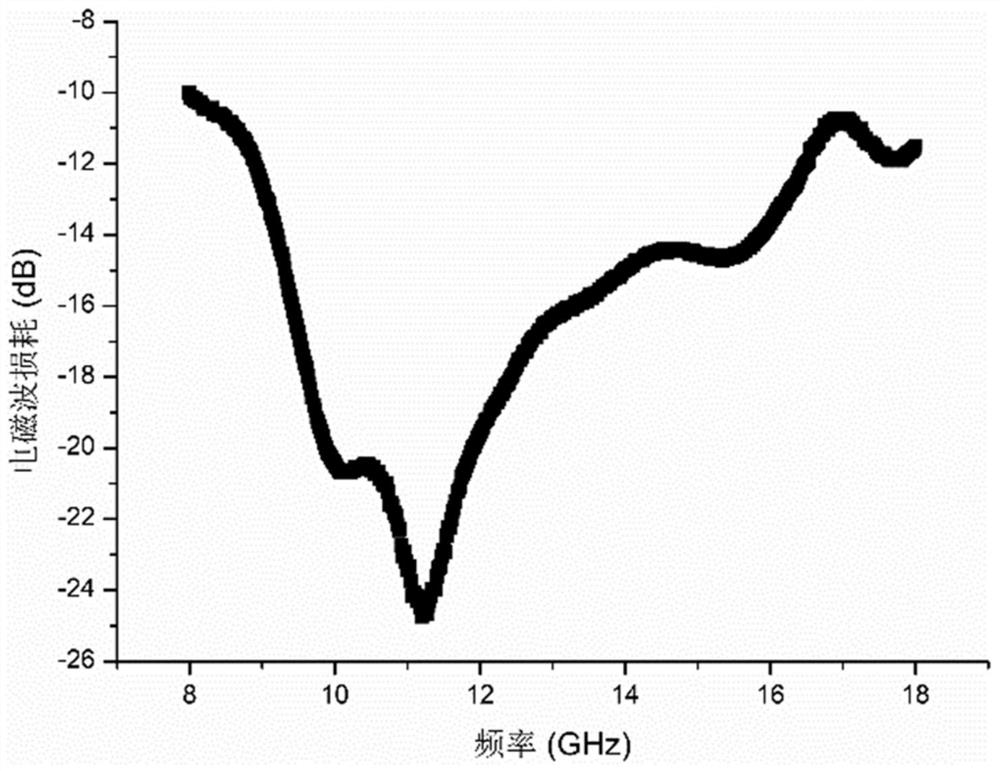

Image

Examples

Embodiment 1

[0035] A sheath-core structure fiber with both infrared and radar stealth, comprising the following raw materials in parts by weight: 10 parts of paraffin wax, 0.7-1.5 parts of electromagnetic wave absorber, and 1 part of high molecular polymer.

[0036] The above-mentioned electromagnetic wave absorber is one or more of iron ferric oxide intercalated graphene oxide, nano iron ferric oxide, and carbon black.

[0037] The above-mentioned high molecular polymer is one or more of polyethylene, polypropylene, and ethylene-vinyl acetate copolymer.

[0038] A method for preparing a skin-core structural fiber with both infrared and radar stealth, the specific steps are as follows:

[0039] (1) Melt 1000g of paraffin wax at 70°C, add 50g of ferric oxide intercalated graphene oxide and 20g of carbon black and stir well to prepare infrared and electromagnetic wave absorbing material S1.

[0040] (2) Melt 50g of polyethylene, 30g of polypropylene, and 20g of ethylene-vinyl acetate copol...

Embodiment 2

[0045] A method for preparing a skin-core structural fiber with both infrared and radar stealth, the specific steps are as follows:

[0046] (1) Melt 1000g of paraffin wax at 70°C, add 100g of nano-ferric oxide and 50g of carbon black and stir well to prepare infrared and electromagnetic wave absorbing material S1.

[0047] (2) Melt 50g of polyethylene, 30g of polypropylene, and 20g of ethylene-vinyl acetate copolymer at 130°C, then add them into the melt of S1, stir thoroughly, stir evenly, and then dry to prepare core material S2.

[0048] (3) Dissolving polyacrylonitrile in N,N-dimethylacetamide, stirring evenly and standing still for 10 h to prepare an external phase spinning solution (polyacrylonitrile solution) with a mass concentration of polyacrylonitrile of 20%.

[0049] (4) S2 is used as the core material (the core material nozzle is controlled at 140° C.), and polyacrylonitrile solution is used as the skin layer material for solution spinning to obtain fibers with a...

Embodiment 3

[0052] A method for preparing a skin-core structural fiber with both infrared and radar stealth, the specific steps are as follows:

[0053] (1) Melt 1000g of paraffin wax at 70°C, add 70g of ferric oxide intercalated graphene oxide and 30g of carbon black and stir well to prepare infrared and electromagnetic wave absorbing material S1.

[0054] (2) Melt 50g of polyethylene, 30g of polypropylene, and 20g of ethylene-vinyl acetate copolymer at 130°C, then add them into the melt of S1, stir thoroughly, and then dry them to prepare the core material S2.

[0055] (3) Dissolving polyacrylonitrile in N,N-dimethylacetamide, stirring evenly and standing still for 10 h to prepare an external phase spinning solution (polyacrylonitrile solution) with a mass concentration of polyacrylonitrile of 20%.

[0056] (4) S2 is used as the core material (the core material nozzle is controlled at 150° C.), and the polyacrylonitrile solution is used as the skin layer material for solution spinning t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com