Sustained or controlled release antibacterial rice bran protein composite membrane as well as preparation method and application thereof

A technology of rice bran protein and rice bran acylated protein, which is applied in the field of food packaging, can solve the problems of undeveloped applications and few antibacterial films, and achieve the effects of long-term effect and timeliness, stable performance and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example is intended to illustrate a method of preparing a slow-release antibacterial rice bran protein composite film.

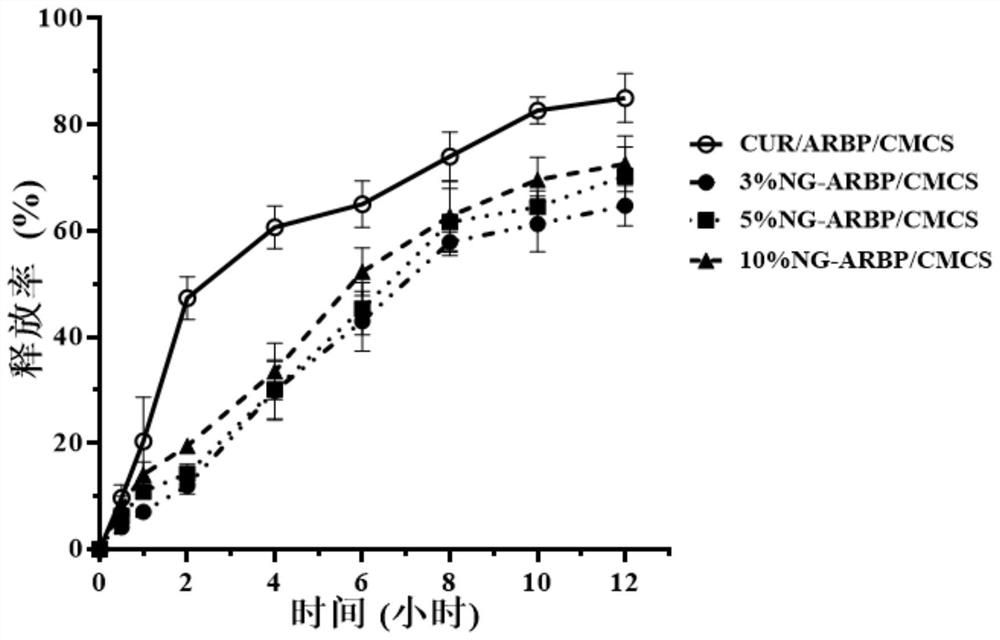

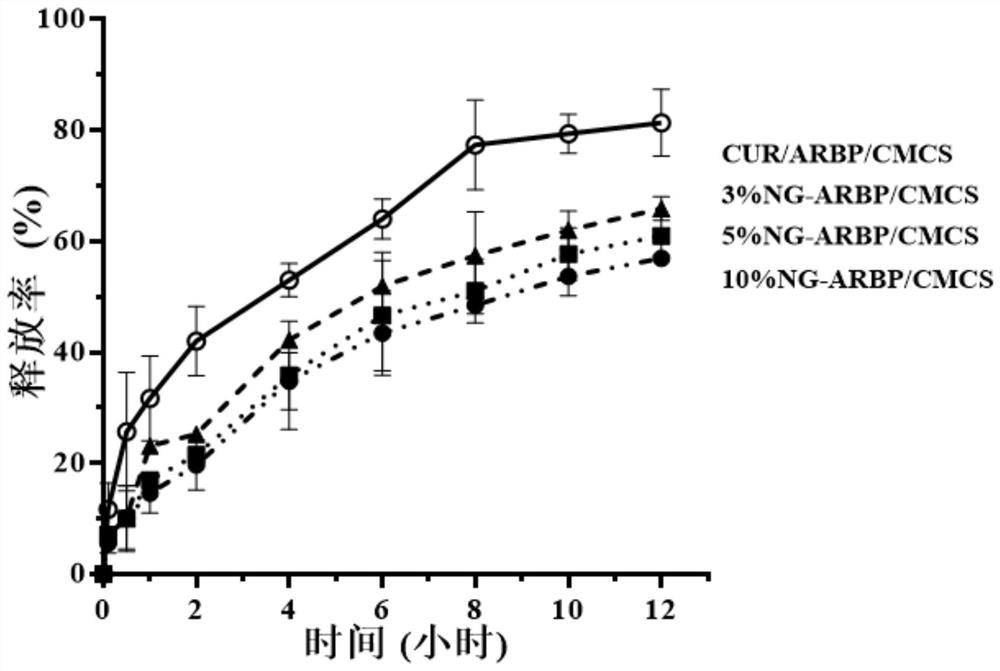

[0043] A method for preparing a slow-release antibacterial rice bran protein composite film, wherein the film base material is a carboxymethyl chitcan (purchased from Sigma) and rice branocycid protein, and antibacterial agent is curcumin (purchased in Mac, Mac) , Additive glycerol, Tween 20 is purchased in Mac, rice bran protein nanogel for laboratory, including:

[0044] (a) Rice bbf bf cruciacification: first addition of rice bran protein solution (2%) into phosphate buffer, constant temperature stirring simultaneously, adding succinic anhydride (15%), and then continues constant temperature (40 ° C) and stir 1.0 M NaOH maintains pH at 8.0, the reaction time is 30 min, and the reaction time is dialysis (the dialysis bag is 3.5 kD, 4 ° C, 24h), and freezing 12h in the refrigerator at -80 ° C, then transfer to -40 ° C The freeze drying machine was l...

Embodiment 2

[0053] This example is intended to illustrate a performance characterization of a slow-release antibacterial rice bran protein composite film.

[0054] The slow-release antibacterial rice bran protein composite membrane prepared in Example 1 was stored at a temperature of 25 ° C and a humidity of 55%, and various properties was measured (as a controlled protein film as a control).

[0055] 1. Determination of film thickness

[0056] The thickness of the film was measured by the screw micrometer, and the thickness of the film was measured. The average value is calculated, and the film thickness is calculated, and in accordance with a certain law, 5 points are random on the film to be filmed, and the result is accurate to 0.001 mm.

[0057] 2. Determination of tensile strength (TS) and fracture elongation (EB)

[0058] The mechanical properties of the anti-controlled release antibacterial rice bran protein composite film were analyzed using a tension tester (Labthink C610M, Shandong...

Embodiment 3

[0071] This example is used to illustrate the antibacterial activity of E. coli by reseudently release the antibacterial rice bran protein composite membrane.

[0072] The composite film having a better composite performance in Example 2, that is, W (ARBP): W (CMCs) is 3: 1, and the amount of ARBPNG is 3%, 5% and 10%, and the antibacterial experimental test of the present embodiment is carried out. Among them, a control is made in a composite film without ARBPNG).

[0073] The antibacterial activity of the composite membrane is used to test the antibacterial activity of E. coli. Press the composite film film 2 × 2 cm 2 Slices of sheets, placed in solution (0.1%, w / v) containing 20 ml of protein (0.1%, w / v), E. coli concentration is 10 3 CFU / ml of centrifuge tubes. The centrifuge tube was incubated in a TS-2102C oscillator; oscillating at 37 ° C and 150 rpm for 24 hours. 0.5 ml of culture solution was collected every 2 hours, and in a 96-well plate was added, the absorbance v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com