Phosphorus-nitrogen type flame retardant as well as preparation method and application thereof

A technology of flame retardant and phosphorus nitrogen, which is applied in the field of flame retardants, can solve the problems of not being resistant to washing, poor hand feeling, etc., and achieve the effects of small loss of strength, environmental protection and pollution-free application, and improved flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

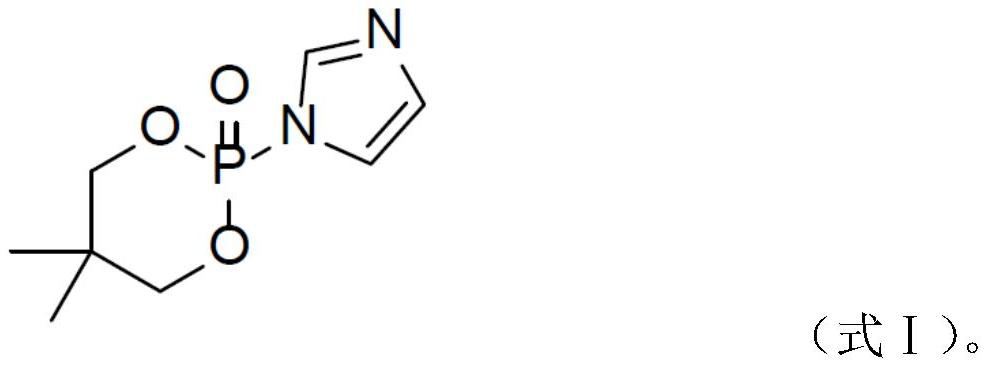

Method used

Image

Examples

Embodiment 1

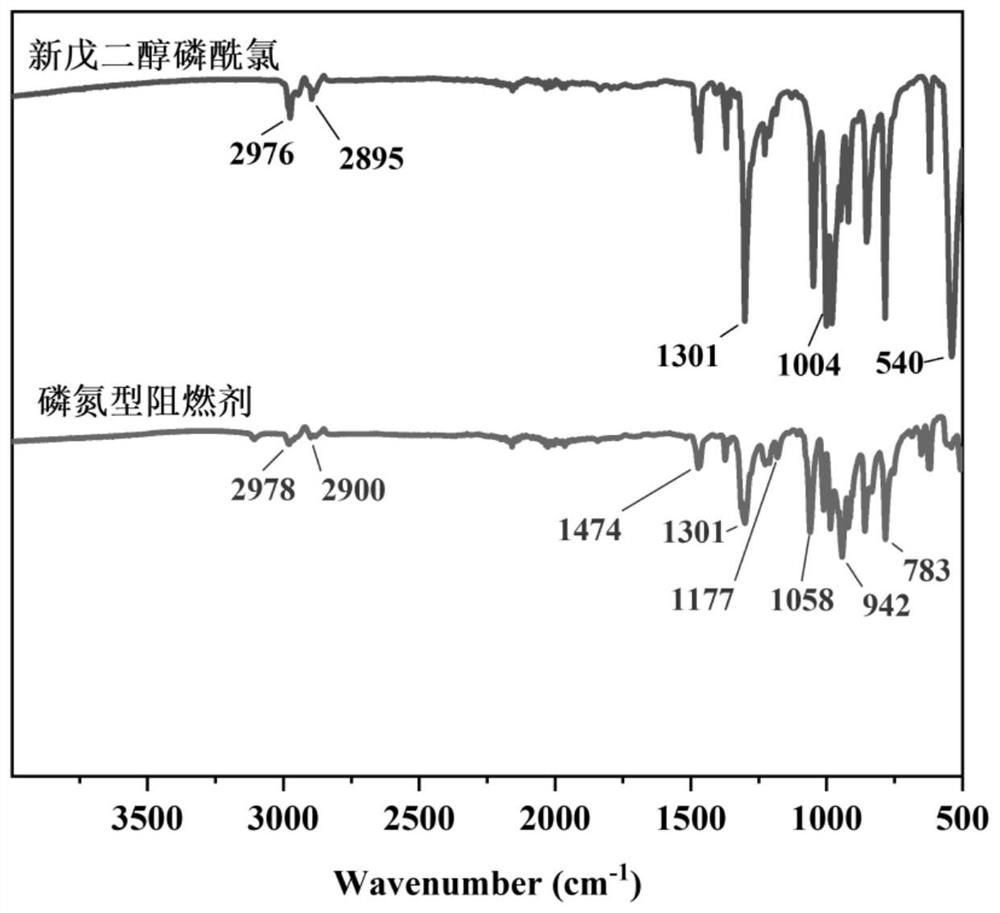

[0035] 1. Synthesis of intermediate neopentyl glycol phosphorus oxychloride

[0036] Add 0.1mol of neopentyl glycol to a three-necked flask equipped with a spherical condenser, thermometer and magnetic stirring device, then add 50mL of dichloromethane as a solvent, stir to completely dissolve neopentyl glycol in the solvent, and keep the temperature at 3°C , and then add 0.11mol phosphorus oxychloride dropwise, after the dropwise addition, the temperature is raised to 55°C, and the reaction is continued for 5h until no hydrogen chloride is released; after the reaction is completed, cool to room temperature, and distill off the solvent and unreacted trichloride under reduced pressure Oxyphosphorus, washed three times with n-hexane, and vacuum-dried to obtain the intermediate neopentyl glycol phosphorus oxychloride.

[0037] 2. Preparation of phosphorus nitrogen flame retardant

[0038] Under the protection of nitrogen atmosphere, dissolve 0.05 mol of imidazole in 50 mL of dich...

Embodiment 2

[0047] 1. Synthesis of intermediate neopentyl glycol phosphorus oxychloride

[0048] Add 0.2mol of neopentyl glycol to a three-neck flask equipped with a spherical condenser, thermometer and magnetic stirring device, then add 100mL of dichloromethane as a solvent, stir to completely dissolve neopentyl glycol in the solvent, and keep the temperature at 3°C , then add 0.22mol phosphorus oxychloride dropwise, after the dropwise addition, the temperature is raised to 55°C, and the reaction is continued for 5h until no hydrogen chloride is released; after the reaction is completed, cool to room temperature, and distill off the solvent and unreacted trichloride under reduced pressure Oxyphosphorus, washed three times with n-hexane, and vacuum-dried to obtain the intermediate neopentyl glycol phosphorus oxychloride.

[0049] 2. Preparation of phosphorus nitrogen flame retardant

[0050] Under the protection of nitrogen atmosphere, dissolve 0.1 mol of imidazole in 100 mL of dichlorom...

Embodiment 3

[0058] 1. Synthesis of intermediate neopentyl glycol phosphorus oxychloride

[0059] Add 0.3mol of neopentyl glycol to a three-necked flask equipped with a spherical condenser, thermometer and magnetic stirring device, then add 150mL of dichloromethane as a solvent, stir to completely dissolve neopentyl glycol in the solvent, and keep the temperature at 3°C , then add 0.33mol phosphorus oxychloride dropwise, after the dropwise addition, the temperature is raised to 55°C, and the reaction is continued for 5h until no hydrogen chloride is released; after the reaction is completed, cool to room temperature, and distill off the solvent and unreacted trichloride under reduced pressure Oxyphosphorus, washed three times with n-hexane, and vacuum-dried to obtain the intermediate neopentyl glycol phosphorus oxychloride.

[0060] 2. Preparation of phosphorus nitrogen flame retardant

[0061] Under the protection of nitrogen atmosphere, dissolve 0.15 mol of imidazole in 150 mL of dichlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com