A kind of high heat resistance explosion-proof glass and its production process

A kind of explosion-proof glass, high heat resistance technology, applied in the direction of coating, can solve the problem of personal injury, burst, can not play the role of fire prevention and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is a high temperature resistant resin, and the high temperature resistant resin is prepared by the following steps:

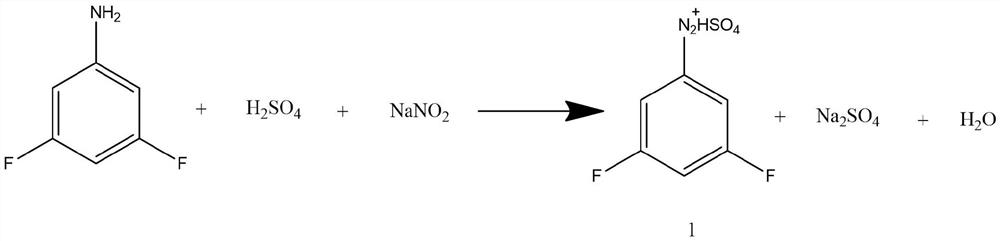

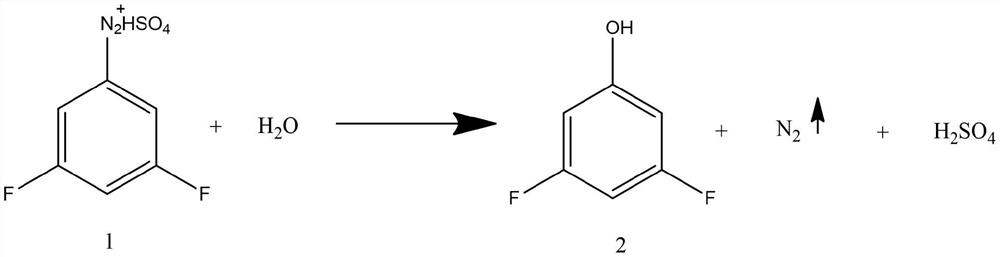

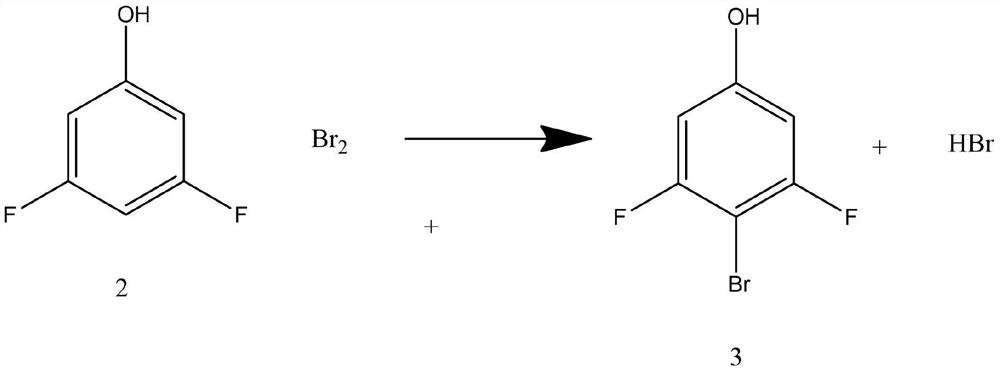

[0042] S1: Add 3,5-difluoroaniline into a three-neck flask equipped with a constant pressure dropping funnel and a stirrer, add glacial acetic acid, and stir until 3 at a temperature of 30°C and a stirring rate of 100r / min. 5-Difluoroaniline is completely dissolved, then add deionized water and continue to stir for 10 minutes, then add concentrated sulfuric acid drop by drop, control the dropping rate at 1 drop / s, keep the temperature of the reaction system not higher than 45°C during the dropping process, add dropwise After the completion, continue to stir the reaction for 10 minutes, then cool the reaction system to 0°C, add the sodium nitrite solution dropwise while stirring at a stirring rate of 500r / min, control the dropping rate at 0.8mL / min, continue to Stir the reaction for 30 minutes, add diethyl ether and continue stirring for 3...

Embodiment 2

[0050] This embodiment is a high temperature resistant resin, and the high temperature resistant resin is prepared by the following steps:

[0051] S1: Add 3,5-difluoroaniline into a three-necked flask equipped with a constant pressure dropping funnel and a stirrer, add glacial acetic acid, and stir until 3 at a temperature of 35°C and a stirring rate of 200r / min. 5-Difluoroaniline is completely dissolved, then add deionized water and continue to stir for 20 minutes, then add concentrated sulfuric acid drop by drop, control the dropping rate at 1 drop / s, keep the temperature of the reaction system not higher than 45°C during the dropping process, add dropwise After the completion, continue to stir the reaction for 20 minutes, then cool the reaction system to 0°C, add the sodium nitrite solution dropwise while stirring at a stirring rate of 800r / min, control the dropping rate at 1mL / min, and continue stirring after the dropping is completed After reacting for 50 minutes, diethy...

Embodiment 3

[0059] This embodiment is a production process of high heat-resistant explosion-proof glass. The high-temperature-resistant resin from Example 1 is melted, and the melted high-temperature-resistant resin is cast on the upper and lower surfaces of the tempered glass to form a thin film, forming A heat-resistant explosion-proof film is used to obtain the high heat-resistant explosion-proof glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com