Scrubbing-resistant antibacterial fireproof environment-friendly children paint and preparation method thereof

A scrub-resistant and environmentally friendly technology, applied in the field of coatings, can solve the problems of short antibacterial validity period, poor scrub resistance, and no fireproof effect, and achieve the effects of prolonging the antibacterial validity period, excellent anti-mold performance, and enhancing anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

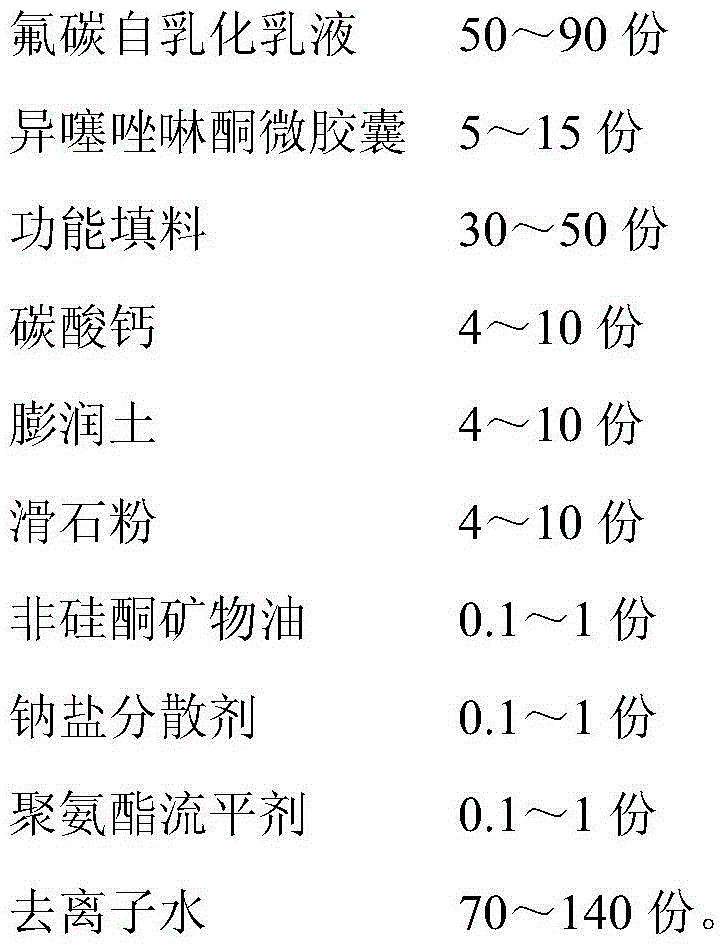

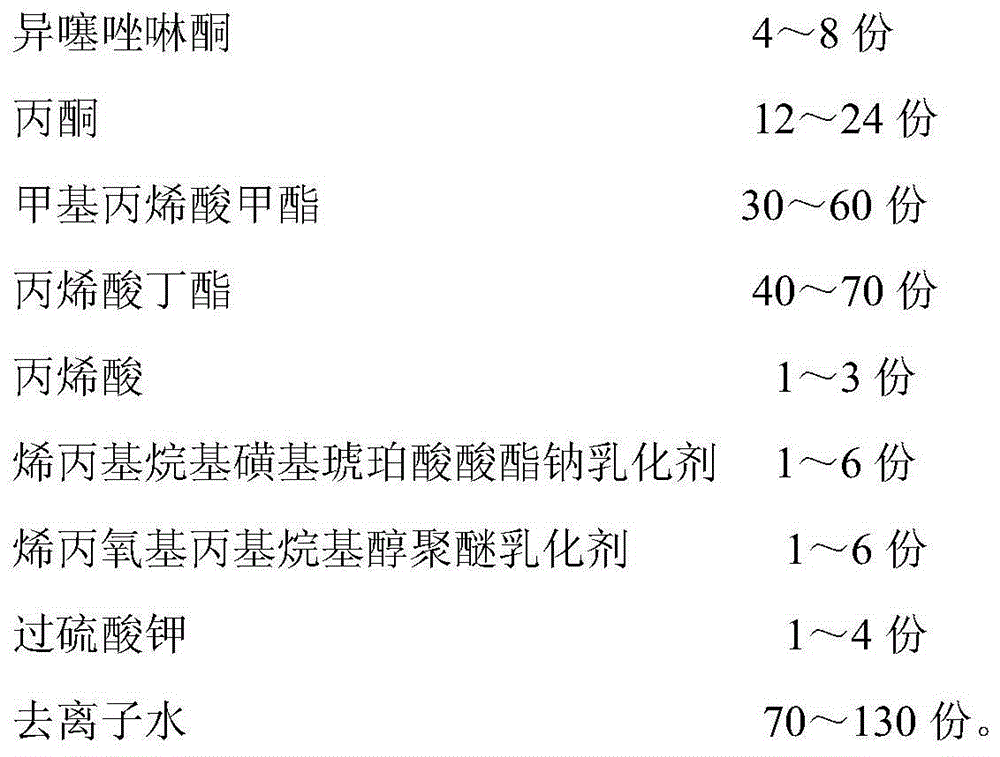

[0033] Scrub-resistant, antibacterial, fireproof, and environment-friendly paint for children of the present invention is prepared according to the following steps:

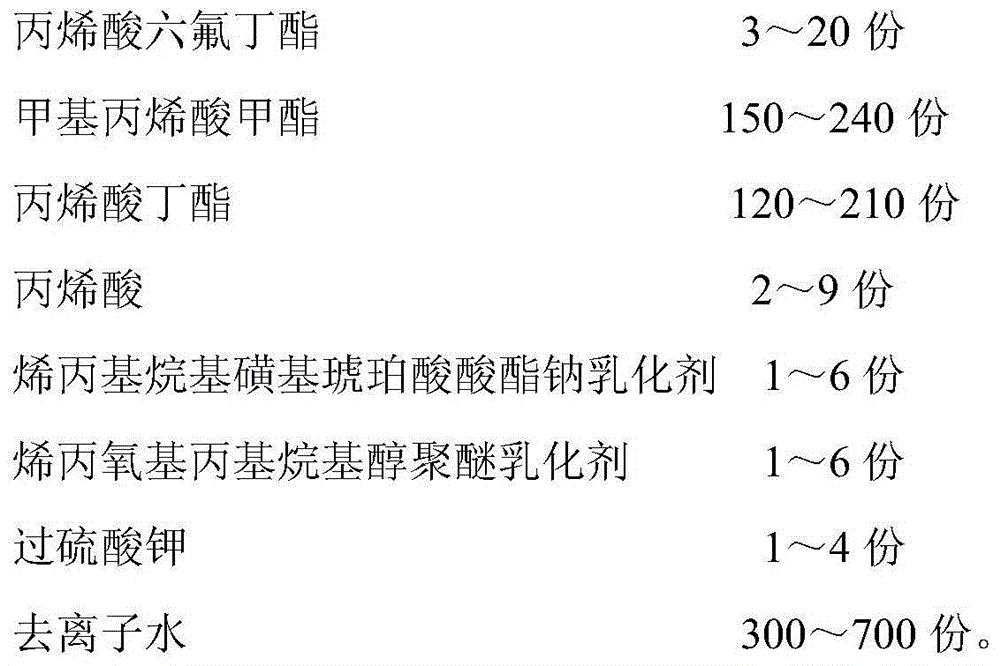

[0034] (1) Fluorocarbon self-emulsifying emulsion, its mass fraction is 50 parts, and its preparation steps are as follows:

[0035] First add 3 parts of hexafluorobutyl acrylate, 150 parts of methyl methacrylate, 120 parts of butyl acrylate, and 2 parts of acrylic acid into a beaker, stir well to obtain a mixed monomer; then add 300 parts of deionized water, 1 part Add allyl alkyl sulfosuccinate sodium emulsifier salt, 1 part of allyloxypropyl alkyl alcohol polyether emulsifier, and 1 part of potassium persulfate into a four-necked bottle, vent nitrogen, and turn on the electric mixer , pre-emulsified for 0.5 hours, and raised the temperature to 80°C; maintained the temperature, evenly added the mixed monomer into the four-necked bottle through the dropping funnel, and finished dropping in 3 hours; after the add...

Embodiment 2

[0048] Scrub-resistant, antibacterial, fireproof, and environment-friendly paint for children of the present invention is prepared according to the following steps:

[0049] (1) Fluorocarbon self-emulsifying emulsion, its mass fraction is 80 parts, and its preparation steps are as follows:

[0050]First add 8 parts of hexafluorobutyl acrylate, 200 parts of methyl methacrylate, 160 parts of butyl acrylate, and 6 parts of acrylic acid into a beaker, stir well to obtain a mixed monomer; then add 500 parts of deionized water, 3 parts Add allyl alkyl sulfosuccinate sodium emulsifier salt, 3 parts of allyloxypropyl alkyl alcohol polyether emulsifier, and 2 parts of potassium persulfate into a four-necked bottle, vent nitrogen, and turn on the electric mixer , pre-emulsified for 0.5 hours, and raised the temperature to 85°C; maintained the temperature, evenly added the mixed monomers into the four-necked bottle through the dropping funnel, and finished dropping in 3.5 hours; after th...

Embodiment 3

[0063] Scrub-resistant, antibacterial, fireproof, and environment-friendly paint for children of the present invention is prepared according to the following steps:

[0064] (1) Fluorocarbon self-emulsifying emulsion, its mass fraction is 60 parts, and its preparation steps are as follows:

[0065] First add 8 parts of hexafluorobutyl acrylate, 170 parts of methyl methacrylate, 150 parts of butyl acrylate, and 4 parts of acrylic acid into a beaker, stir well to obtain a mixed monomer; then add 400 parts of deionized water, 2 parts Add allyl alkyl sulfosuccinate sodium emulsifier salt, 3 parts of allyloxypropyl alkyl alcohol polyether emulsifier, and 2 parts of potassium persulfate into a four-necked bottle, vent nitrogen, and turn on the electric mixer , pre-emulsified for 0.5 hours, and raised the temperature to 85°C; maintained the temperature, evenly added the mixed monomers into the four-necked bottle through the dropping funnel, and finished dropping in 3.5 hours; after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com