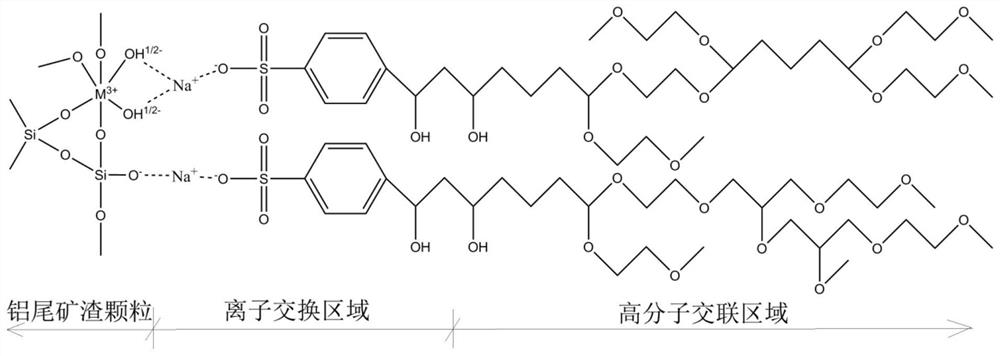

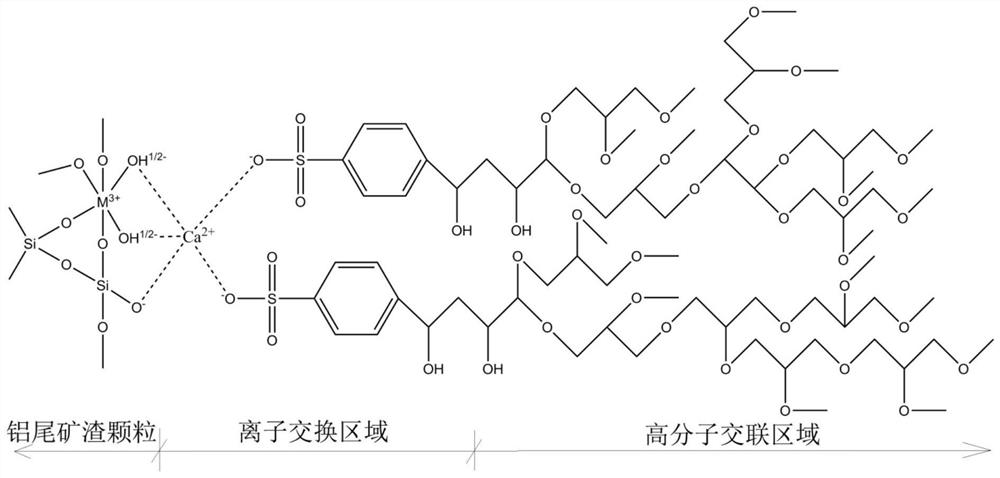

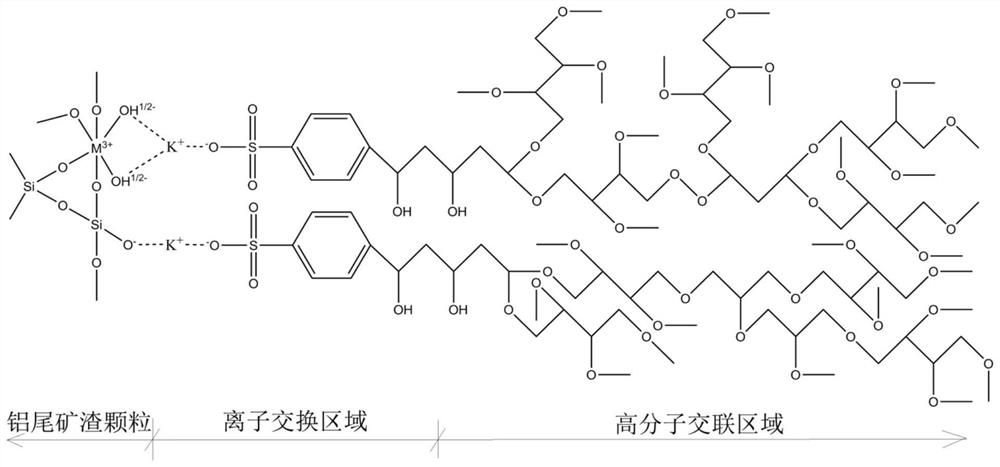

Aluminum tailing slag improvement method based on ion exchange and cross-linking reaction

A technology of cross-linking reaction and ion exchange, which is applied in the field of soil conditioning materials or soil stabilizing materials, can solve the problems of high curing cost, low stiffness and strength, reduced curing strength and durability, etc., so as to improve the cross-linking reaction rate and high Ion exchange rate, effect of improving improvement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0161] This embodiment is an example of the method for improving aluminum tailings slag based on ion exchange and cross-linking reactions described in the present invention, and is an application test of improving aluminum tailings slag in a laboratory.

[0162] The improvement method of aluminum tailings slag based on ion exchange and cross-linking reaction, including aluminum tailings slag modifier and aluminum tailings slag improvement steps:

[0163] (1) Aluminum tailings slag improver

[0164] Aluminum tailings slag modifiers include alkali-reducing curing agents, ion-exchange stabilizers and particle-bonding curing agents,

[0165] The alkali-reducing curing agent is a compound capable of reducing the alkalinity of aluminum tailings, including hydroxyl compounds and epoxy compounds,

[0166] In the process of improving aluminum tailings slag in the laboratory, a mixed solution of ethylene glycol and epichlorohydrin was used.

[0167] The ion exchange stabilizer include...

Embodiment 3

[0256] This embodiment is another example of the method for improving aluminum tailings slag based on ion exchange and cross-linking reaction of the present invention, and is an application example of improving aluminum tailings slag roadbed in road engineering.

[0257] The improvement method of aluminum tailings slag based on ion exchange and cross-linking reaction, including aluminum tailings slag modifier and aluminum tailings slag improvement steps:

[0258] (1) Aluminum tailings slag improver

[0259] Aluminum tailings slag modifiers include alkali-reducing curing agents, ion-exchange stabilizers and particle-bonding curing agents,

[0260] The alkali-reducing curing agent is a compound capable of reducing the alkalinity of aluminum tailings, including hydroxyl compounds and epoxy compounds,

[0261] In the process of improving the roadbed of aluminum tailings slag in road engineering, a mixed solution of butylene glycol and epichlorohydrin was used.

[0262] The ion e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com