Preparation method of Bi-MoS2 nano composite material for electrocatalytic synthesis of ammonia

A nano-composite material and technology of composite materials, which are applied in the field of electrocatalytic nitrogen reduction electrode materials, can solve the problems of no report on electrocatalytic ammonia synthesis, and achieve the effects of excellent electrocatalytic ammonia synthesis performance, excellent electrochemical activity, and good catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1, the preparation of molybdenum disulfide

[0047] Dissolve 2mmol sodium molybdate dihydrate and 8mmol thiourea in 44ml deionized water, and stir for 0.5h.

[0048] Transfer to a polytetrafluoroethylene stainless steel reaction kettle, seal and keep heating at 200°C in an oven for 24h.

[0049] Naturally cooled to room temperature, washed with deionized water and ethanol four times, and vacuum-dried at 60°C for 12 hours to obtain molybdenum disulfide.

Embodiment 2

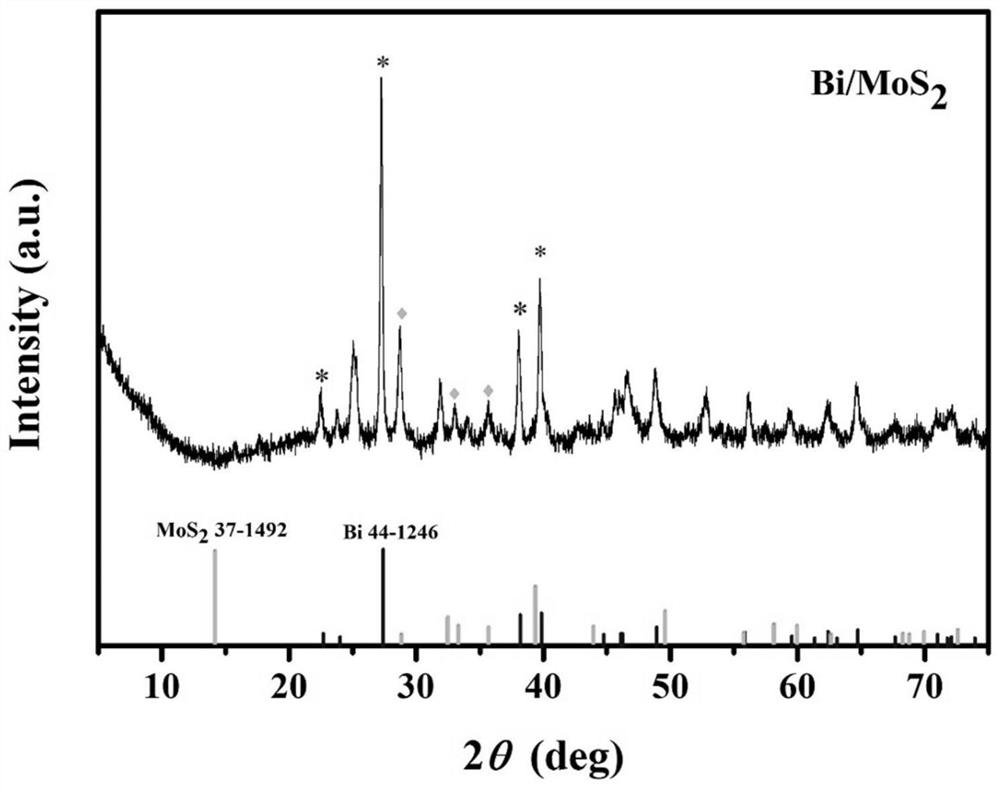

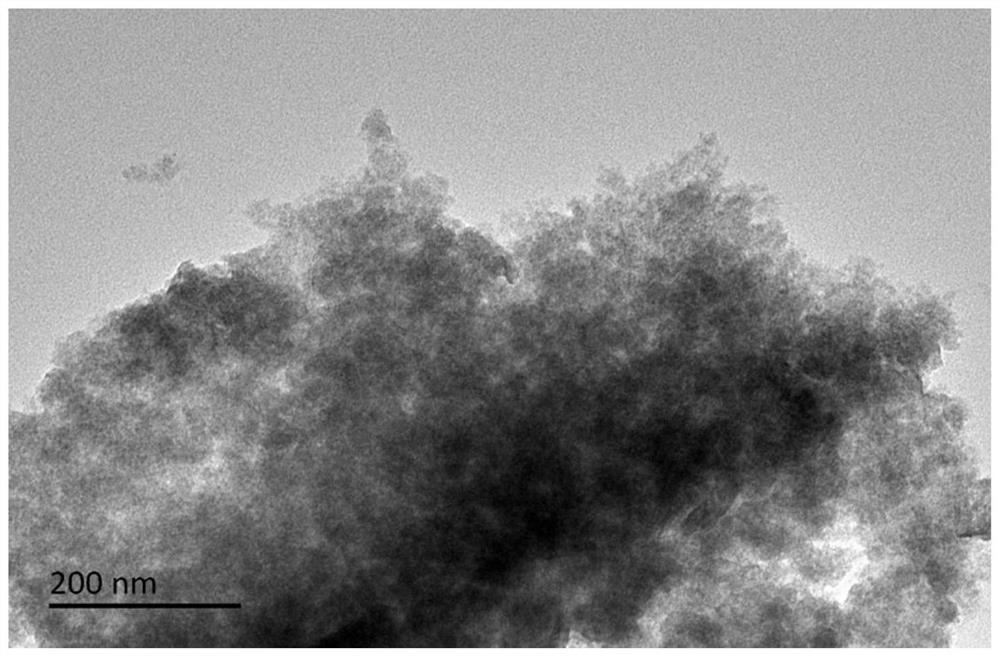

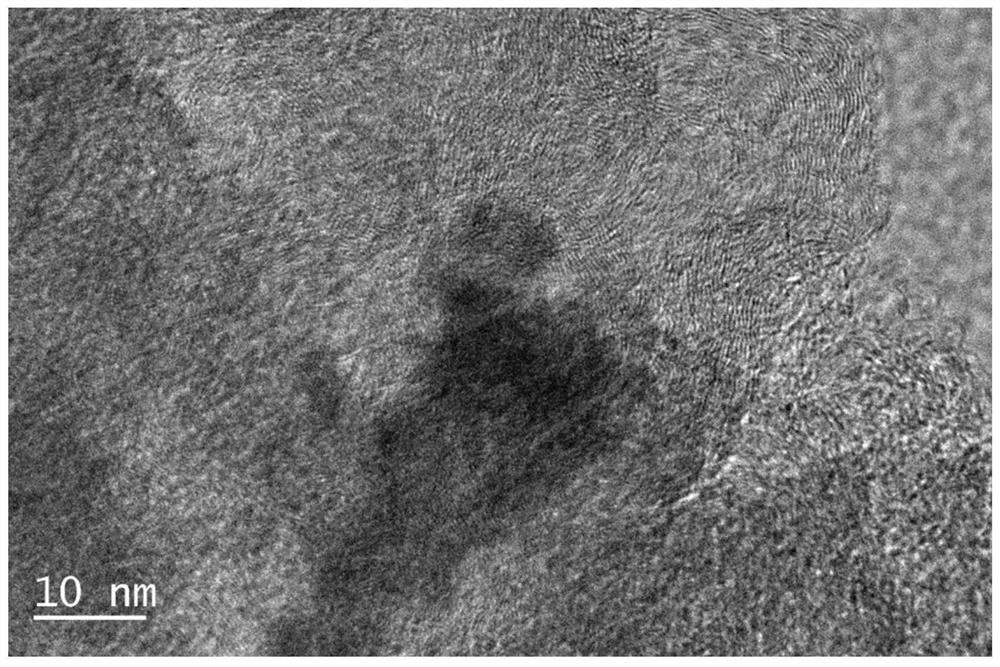

[0050] Example 2, Bi-MoS 2 Preparation of nanocomposites

[0051] 10 mg of molybdenum disulfide prepared in Example 1 was completely dispersed in 10 ml of anhydrous ethylene glycol, and after ultrasonication for 2 hours, 5 ml of ethylene glycol solution and 1.4 mmol of bismuth nitrate pentahydrate were added to obtain a mixed solution.

[0052] The mixed solution was vigorously stirred for 12 hours, ultrasonicated for 15 minutes, and then transferred to a polytetrafluoroethylene-lined stainless steel reactor for hydrothermal reaction at 180°C for 16 hours.

[0053] The final product was centrifuged, washed with ethanol for 4 times and dried in vacuum to obtain Bi-MoS 2 nanocomposites.

Embodiment 3

[0054] Example 3, Bi-MoS 2 Preparation of nanocomposites

[0055] 5 mg of molybdenum disulfide prepared in Example 1 was completely dispersed in 10 ml of anhydrous ethylene glycol, and after ultrasonication for 2 hours, 5 ml of ethylene glycol solution and 1 mmol of bismuth nitrate pentahydrate were added to obtain a mixed solution.

[0056] The mixed solution was vigorously stirred for 12 hours, ultrasonicated for 15 minutes, and transferred to a polytetrafluoroethylene-lined stainless steel reactor for hydrothermal reaction at 160°C for 16 hours.

[0057] The final product was centrifuged, washed with ethanol for 4 times and dried in vacuum to obtain Bi-MoS 2 nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com