Oxide up-conversion luminescent material and preparation method thereof

A technology of luminescent materials and oxides, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of inability to obtain high-purity monoclinic MO, improper control of doping concentration, and difficulty in realizing it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing the above-mentioned oxide up-conversion luminescent material, comprising the following steps:

[0043] Weighing solid compounds containing M element, Ln element, Li element and Ta element respectively according to the stoichiometric ratio, mixing uniformly, and grinding to obtain the mixture;

[0044] Calcining the mixture at 1200-1600°C for 3-5 hours to obtain a sintered body;

[0045] After grinding the sintered body, the oxide up-conversion luminescent material is obtained.

[0046] Wherein, the solid compound includes oxide, carbonate, nitrate and halide, and the solid compound containing M element, Ln element, Li element and Ta element is an oxide compound containing M element, Ln element, Li element and Ta element. at least one of compounds, carbonates, nitrates or halides. The grinding is preferably wet mechanical ball milling for 10 hours, and the calcination temperature is preferably 1300-1450°C.

[00...

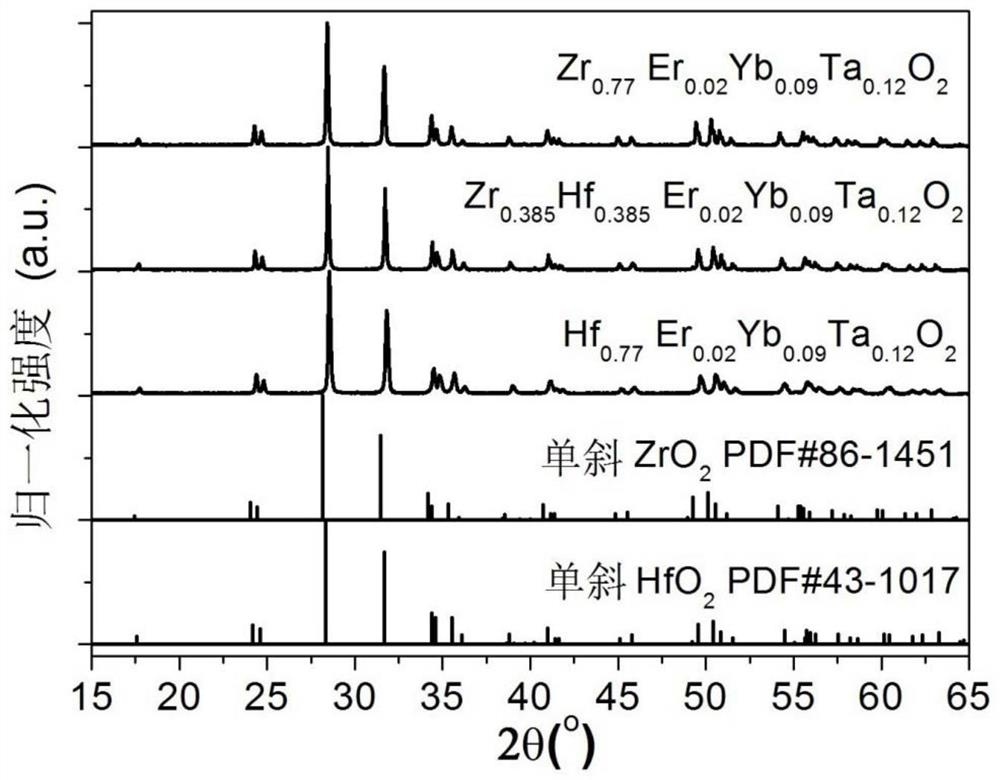

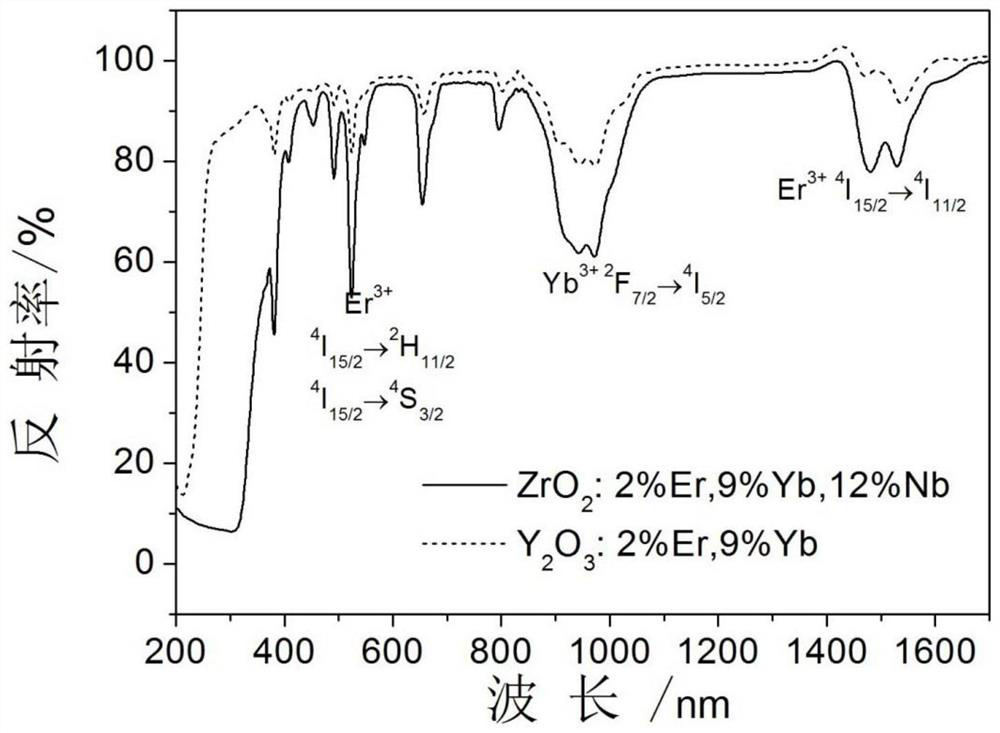

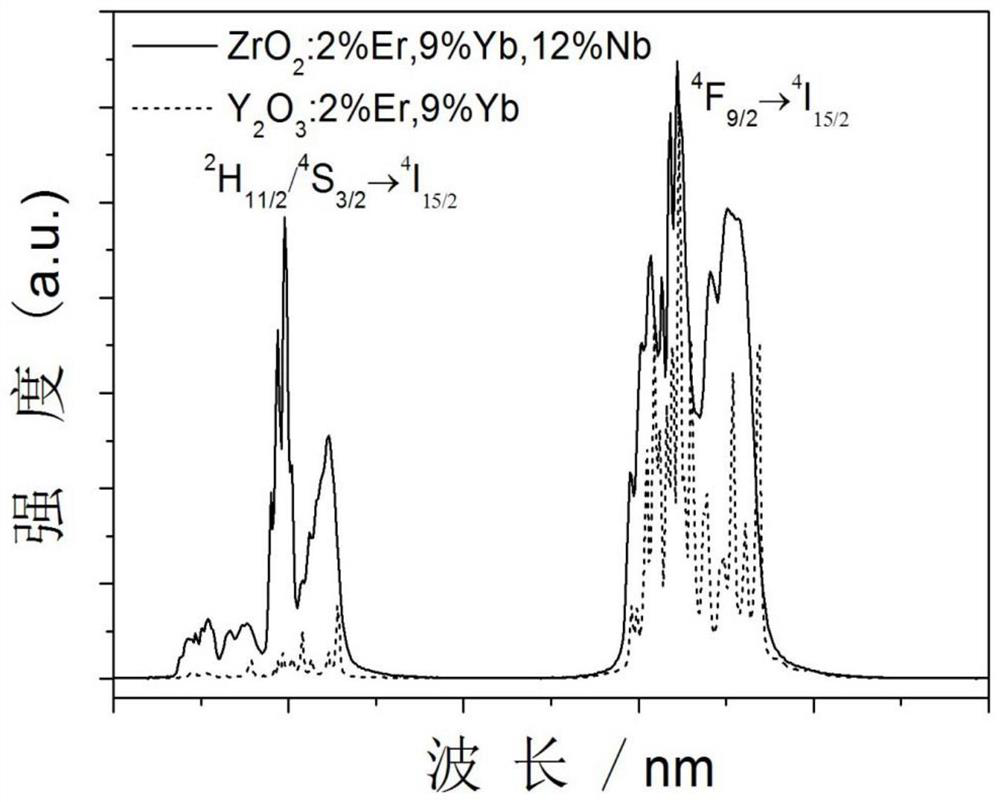

Embodiment 1

[0050] Zr 0.77 Er 0.02 Yb 0.09 Ta 0.12 o 2 Oxide up-conversion phosphor, the preparation process is as follows:

[0051] Weigh high-purity ZrO according to stoichiometric ratio 2 、Er 2 o 3 , Yb 2 o 3 and Ta 2 o 5 (In order to avoid impurity phases due to uneven grinding, the Ta element is in excess of ~9% relative to the rare earth ions when weighing), put it in a zirconia ball mill jar, add an appropriate amount of alcohol, use zirconia balls as the grinding medium, and use a planetary ball mill Grind for 10 hours, then dry in an electric oven for 10 hours, and collect a fine powder sample that is uniformly mixed by vibrating sieving;

[0052] Put it into a high-purity corundum crucible, and keep it warm at 1450°C for 4 hours in the air;

[0053] After the material is cooled and discharged, it is slightly ground to obtain a high-efficiency oxide up-conversion luminescent material.

Embodiment 2

[0055] Zr 0.385 f 0.385 Er 0.02 Yb 0.09 Ta 0.12 o 2 Oxide up-conversion phosphor, the preparation process is as follows:

[0056] Weigh high-purity ZrO according to stoichiometric ratio 2 , HfO 2 、Er 2 o 3 , Yb 2 o 3 and Ta 2 o 5 (In order to avoid impurity phases due to uneven grinding, the Ta element is in excess of ~9% relative to the rare earth ions when weighing), put it in a zirconia ball mill jar, add an appropriate amount of alcohol, use zirconia balls as the grinding medium, and use a planetary ball mill Grind for 10 hours, then dry in an electric oven for 10 hours, and collect a fine powder sample that is uniformly mixed by vibrating sieving;

[0057] Put it into a high-purity corundum crucible, and keep it warm at 1450°C for 4 hours in the air;

[0058] After the material is cooled and discharged, it is slightly ground to obtain a high-efficiency oxide up-conversion luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com