Tristyrylphenol block polyether, sulfate ammonium salt and preparation method thereof

A technology of tristyryl phenol and block polyether, applied in the field of surfactants, can solve the problems of great influence on product quality, great influence on reaction temperature, wide molecular weight distribution, etc., achieve light product color and reduce Kraft point , the effect of narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

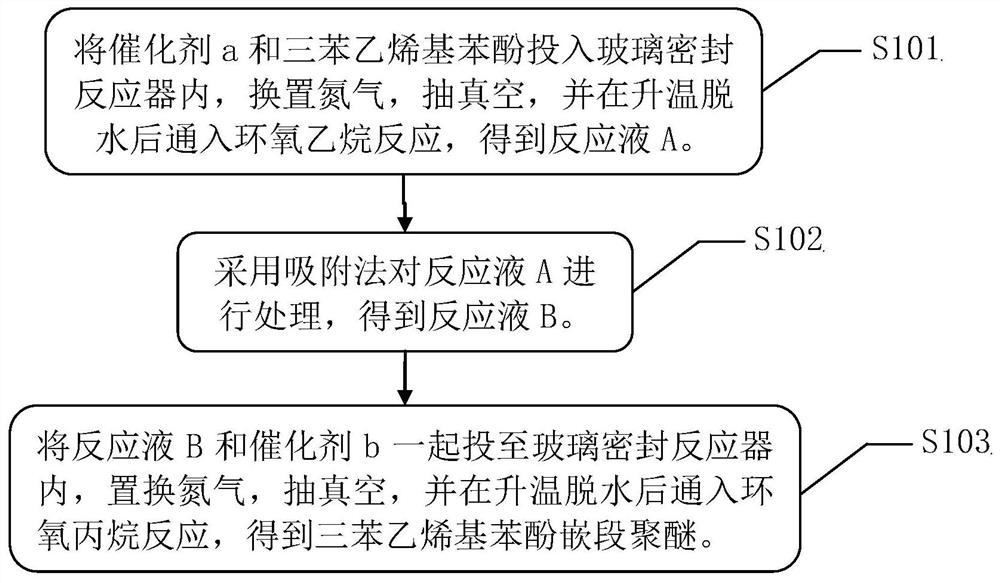

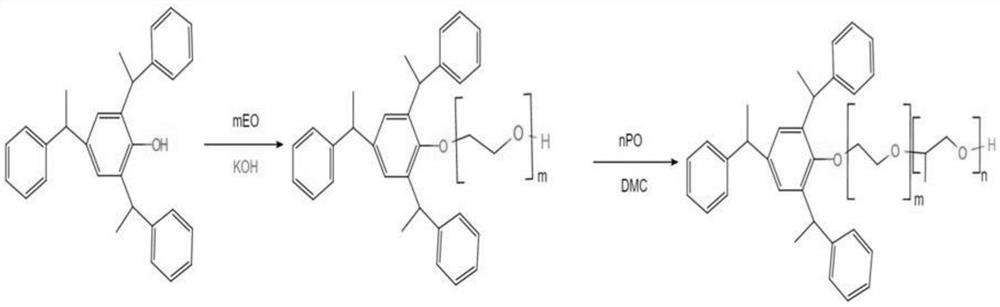

[0032] Such as figure 1 Shown, the preparation method of tristyrylphenol block polyether of the present invention comprises the following steps:

[0033] Step S101. Put catalyst a and tristyryl phenol into a glass-sealed reactor, replace nitrogen (preferably replace nitrogen more than 2 times), vacuumize, and pass through ethylene oxide to react after heating up and dehydrating to obtain a reaction solution A; wherein, the temperature of heating and dehydration is 110°C, and the dehydration time is 1h, and ethylene oxide is slowly introduced at 110°C to 120°C, until the reaction pressure does not drop significantly after adding, the material is discharged to obtain the reaction solution A; And the dosage of catalyst a is preferably 3‰ of the total mass of tristyrylphenol and ethylene oxide.

[0034] Step S102. The reaction solution A is treated by an adsorption method, specifically: adding an adsorbent, diatomaceous earth, phosphoric acid and deionized water to the reaction s...

Embodiment 1

[0047] First, put 1.76g KOH and 282g tristyrylphenol into a 2.5L glass-sealed reactor, and replace N three times. 2 Finally, vacuumize and heat up to 110°C for 1 hour of dehydration; then slowly feed 306g of ethylene oxide at 110°C to 120°C for reaction until the reaction pressure does not drop significantly, stop the reaction, and discharge the material into a 2L four-necked flask; Then add adsorbent, diatomaceous earth, phosphoric acid and deionized water, gradually increase the temperature and vacuum dehydration, vacuum dehydration at 110°C for 1.5h, and filter while hot; finally pour the filtrate and 0.2g of DMC catalyst into a clean 2.5 L glass-sealed reactor, and replaced N 3 times 2 Then vacuumize to the highest level, stop vacuuming after heating up to 100°C, start to slowly feed 1412g of propylene oxide to react, control the reaction temperature between 110°C and 120°C, until the reaction pressure does not drop significantly, stop the reaction, discharge, A tristyryl...

Embodiment 2

[0049] First, put 2.34g KOH and 268g tristyrylphenol into a 2.5L glass-sealed reactor, and replace N three times. 2 Finally, vacuumize and heat up to 110°C for 1 hour of dehydration; then slowly feed 512g of ethylene oxide at 110°C to 120°C for reaction until the reaction pressure does not drop significantly, stop the reaction, and discharge the material into a 2L four-necked flask; Then add adsorbent, diatomaceous earth, phosphoric acid and deionized water, gradually increase the temperature and vacuum dehydration, vacuum dehydration at 110°C for 1.5h, and filter while hot; finally pour the filtrate and 0.2g of DMC catalyst into a clean 2.5 L glass-sealed reactor, and replaced N 3 times 2 Then vacuumize to the highest level, stop vacuuming after heating up to 100°C, start to slowly feed 1150g of propylene oxide to react, control the reaction temperature between 110°C and 120°C, until the reaction pressure does not drop significantly, stop the reaction, discharge, A tristyryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com