Ceramsite preparation method using waste incineration fly ash and ceramsite prepared by method

A technology for waste incineration fly ash and ceramsite, which is applied in the field of waste incineration fly ash resource utilization, can solve the problems of low dosage of waste incineration fly ash, poor pressure strength of ceramsite cylinder and high melting temperature, and achieves high efficiency and large scale. Disposal and utilization, excellent performance, the effect of reducing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Use waste incineration fly ash as raw material, add limestone, fly ash, and clay, and control the mass ratio of the main components of the system. After mixing with water evenly, pelletize through a pelletizer to obtain ceramsite green pellets, and dry the pellets in an oven. , Muffle furnace roasting, you can prepare ceramsite.

[0022] In this embodiment, the main component mass ratio is: CaO / SiO 2 =0.3, (SiO 2 +Al 2 o 3 ) / (CaO+Fe 2 o 3 +MgO)=6.

[0023] In this embodiment, the particle size of the green pellets is 10mm.

[0024] In this embodiment, the water content of the raw balls is 20%.

[0025] In this embodiment, the firing temperature is 1050°C.

[0026] In this embodiment, the firing time is 15 minutes.

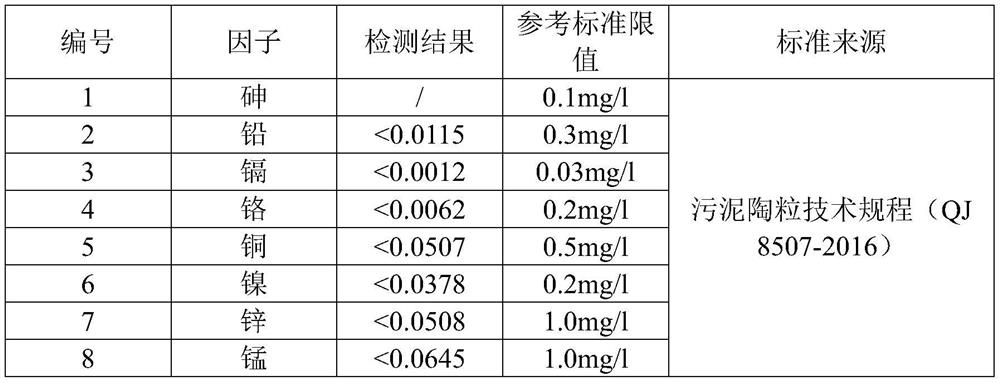

[0027] The ceramsite bulk density that present embodiment 1 obtains is 530kg / m 3 , the cylinder compressive strength is 8MPa, and the 1h water absorption rate is 5%. The dioxin content, leachable heavy metal content, soluble chlorine content, sulfi...

Embodiment 2

[0029] Use waste incineration fly ash as raw material, add limestone, clay, and sludge, and control the mass ratio of the main components of the system. After mixing evenly with water, pelletize through a pelletizer to obtain green pellets of ceramsite. The pellets are dried in an oven, The ceramsite can be prepared by roasting in a muffle furnace.

[0030] In this embodiment, the main component mass ratio is: CaO / SiO 2 =0.25, (SiO 2 +Al 2 o 3 ) / (CaO+Fe 2 o 3 +MgO)=7.

[0031] In this embodiment, the particle size of the green pellets is 10mm.

[0032] In this embodiment, the water content of the raw balls is 20%.

[0033] In this embodiment, the firing temperature is 900°C.

[0034] In this embodiment, the firing time is 10 minutes.

[0035] The ceramsite bulk density that present embodiment 2 obtains is 510kg / m 3 , the cylinder compressive strength is 5MPa, and the 1h water absorption rate is 6%. The dioxin content, leachable heavy metal content, soluble chlorine c...

Embodiment 3

[0037] Use waste incineration fly ash as raw material, add limestone, fly ash, clay, sludge, and control the mass ratio of the main components of the system, mix with water evenly, and pelletize through a pelletizer to obtain ceramsite raw pellets, raw pellets After drying in an oven and firing in a muffle furnace, ceramsite can be prepared.

[0038] In this embodiment, the main component mass ratio is: CaO / SiO 2 =0.2, (SiO 2 +Al 2 o 3 ) / (CaO+Fe 2 o 3 +MgO)=8.

[0039] In this embodiment, the particle size of the green pellets is 20mm.

[0040] In this embodiment, the water content of the raw balls is 9%.

[0041] In this embodiment, the firing temperature is 800°C.

[0042] In this embodiment, the firing time is 5 minutes.

[0043] The ceramsite bulk density that present embodiment 3 obtains is 500kg / m 3 , the cylinder compressive strength is 7MPa, and the 1h water absorption rate is 9.5%. The dioxin content, leaching heavy metal content, soluble chlorine content, sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com