A kind of manufacturing method of sky blue glass bottle

A manufacturing method and a technology of glass bottles, which are applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems that colorant raw materials cannot be completely uniformly colored, uneven blending of raw materials, and uneven color of finished products, etc., to achieve Improve color uniformity, improve production efficiency, and reduce color error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

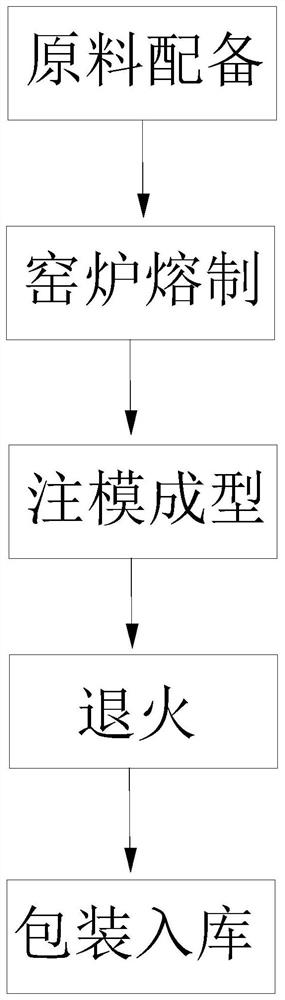

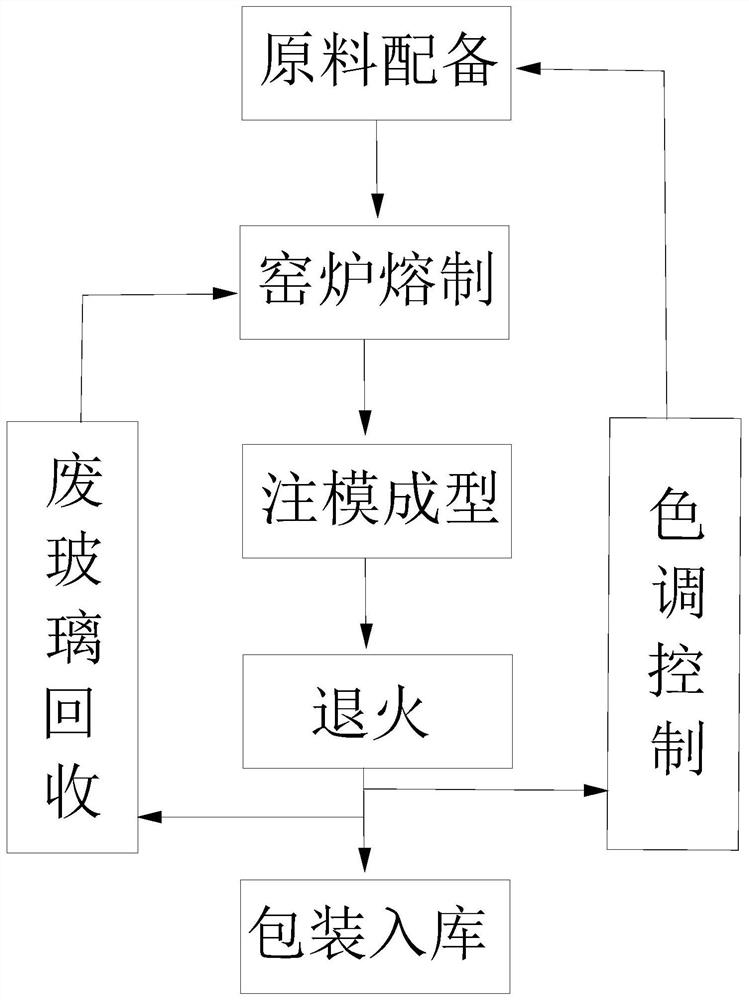

Method used

Image

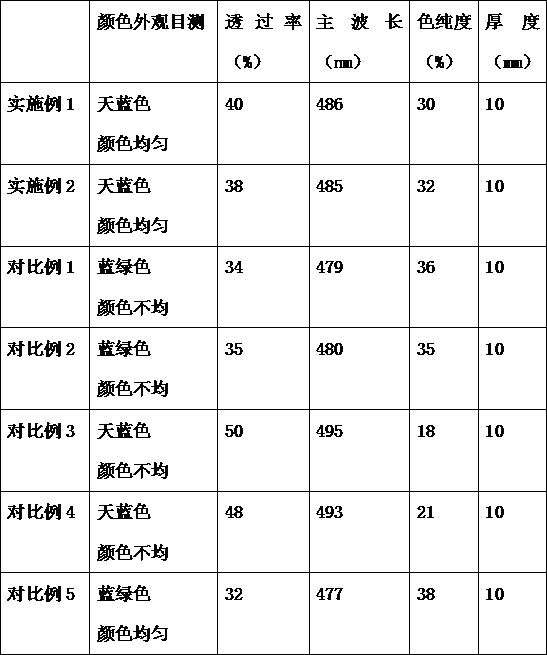

Examples

Embodiment 1

[0039] A method for manufacturing a sky blue glass bottle, comprising the steps of:

[0040] (1) Raw material configuration: 100kg of silica sand, 32kg of soda ash, 31.4kg of limestone, 14kg of feldspar powder and 2.8kg of small materials are physically mixed for 3 minutes;

[0041] The small material includes 0.02kg of cobalt oxide, 0.8kg of copper oxide and 1.97kg of Glauber's salt; the small material is that 0.02kg of cobalt oxide and 0.4kg of copper oxide are firstly mixed with physical stirring for 3 minutes; then the remaining 0.4kg Copper oxide and 1.97kg of Glauber's salt were added to carry out physical stirring and blending for 3 minutes to obtain;

[0042] (2) Furnace melting to obtain molten glass: put the evenly blended raw materials into the kiln, and keep the kiln temperature at 1580±10℃;

[0043] (3) Glass liquid injection molding;

[0044] (4) Annealing: After annealing the molded product at a temperature of 550 °C for 8 minutes, it is cooled naturally to ob...

Embodiment 2

[0047] A method for manufacturing a sky blue glass bottle, comprising the steps of:

[0048] (1) Raw material configuration: 85kg of silica sand, 30kg of soda ash, 30kg of limestone, 15kg of feldspar powder and 2.8kg of small materials are physically stirred and blended for 3 minutes;

[0049] The small material includes 0.02kg of cobalt oxide, 0.8kg of copper oxide and 1.97kg of Glauber's salt; the small material is that 0.02kg of cobalt oxide and 0.4kg of copper oxide are firstly mixed with physical stirring for 3 minutes; then the remaining 0.4kg Copper oxide and 1.97kg of Glauber's salt were added to carry out physical stirring and blending for 3 minutes to obtain;

[0050](2) Furnace melting to obtain molten glass: first put 65kg of broken glass into the kiln, then put the evenly blended raw materials into the kiln, and the kiln temperature is kept at 1580±10℃;

[0051] Broken glass is recovered from waste glass. The specific recycling of waste glass is as follows: the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com