Electric-field-assisted water-guided laser cutting device

A laser cutting and electric field-assisted technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high nozzle cost and difficulty in further improving processing accuracy, and achieve the goal of reducing manufacturing difficulty and cost and improving processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

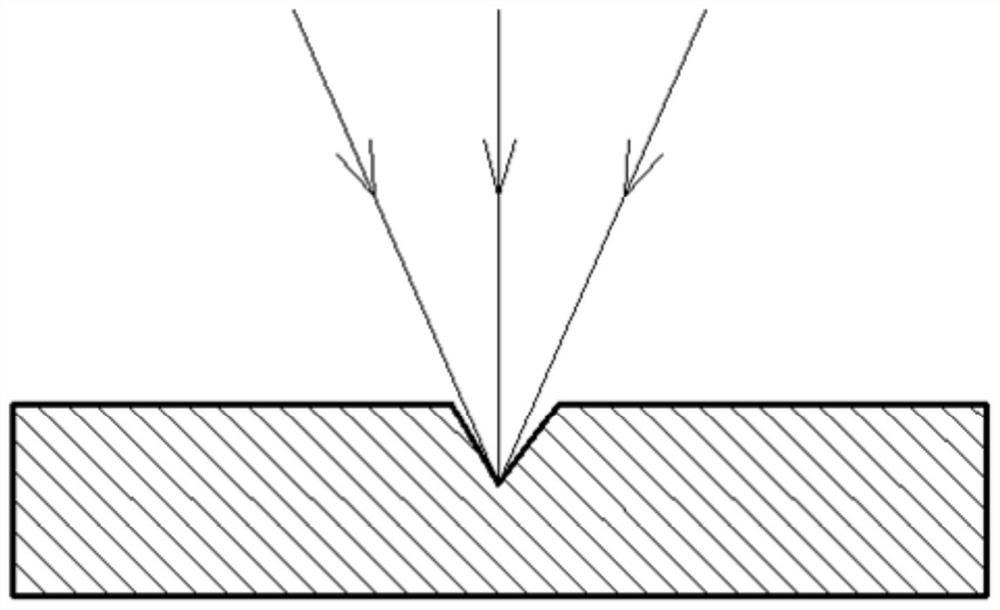

[0017] refer to figure 1 , The electric field assisted water conduction laser cutting device of the present invention includes a lens holder 1, a water chamber 2, a gas chamber 3, a substrate 5, a lens 6, a plane lens 7, a nozzle 8, and a high voltage power supply 9. Wherein the lens 6 is installed on the lens holder 1 . A liquid inlet 2-2 is opened on the water chamber 2, and liquid can enter the liquid chamber 2-1 through the liquid inlet 2-2. The water chamber 2 is connected with the gas chamber 3, and the plane lens 7 is installed in the middle section of the water chamber 2. The nozzle 8 is installed at the bottom of the water chamber 2, and the liquid in the liquid chamber 2-1 can flow out from the nozzle 8 under the action of external pressure. The gas chamber 3 is provided with a gas inlet 3-2, and external air can enter the gas chamber 3-1 through the gas inlet 3-2 and be discharged from the holes on the gas chamber 3. Both the nozzle 8 and the substrate 5 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com