Glass fiber coated filter cloth and manufacturing method thereof

A manufacturing method and filter cloth technology, applied in membrane filters, separation methods, chemical instruments and methods, etc., can solve the problems of reduced use effect, single weaving method, insufficient use of glass fiber coated filter cloth, etc. Light, improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

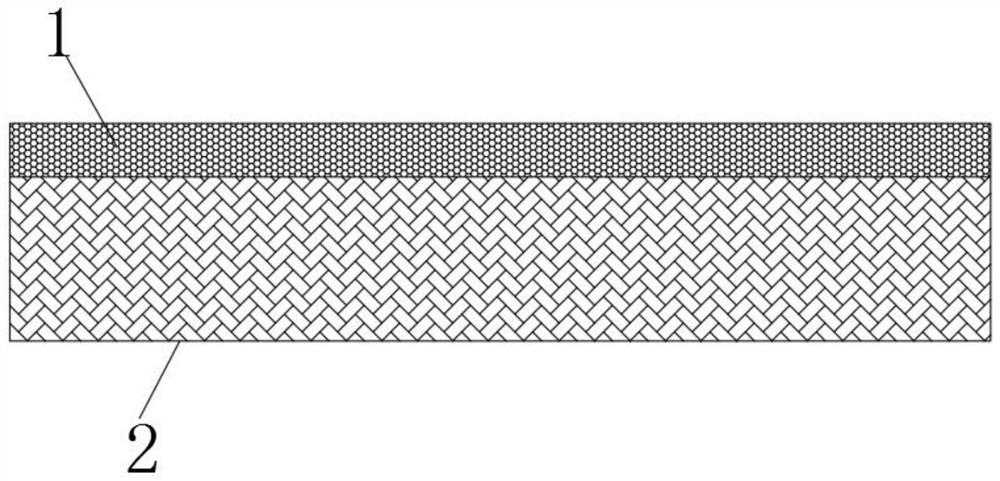

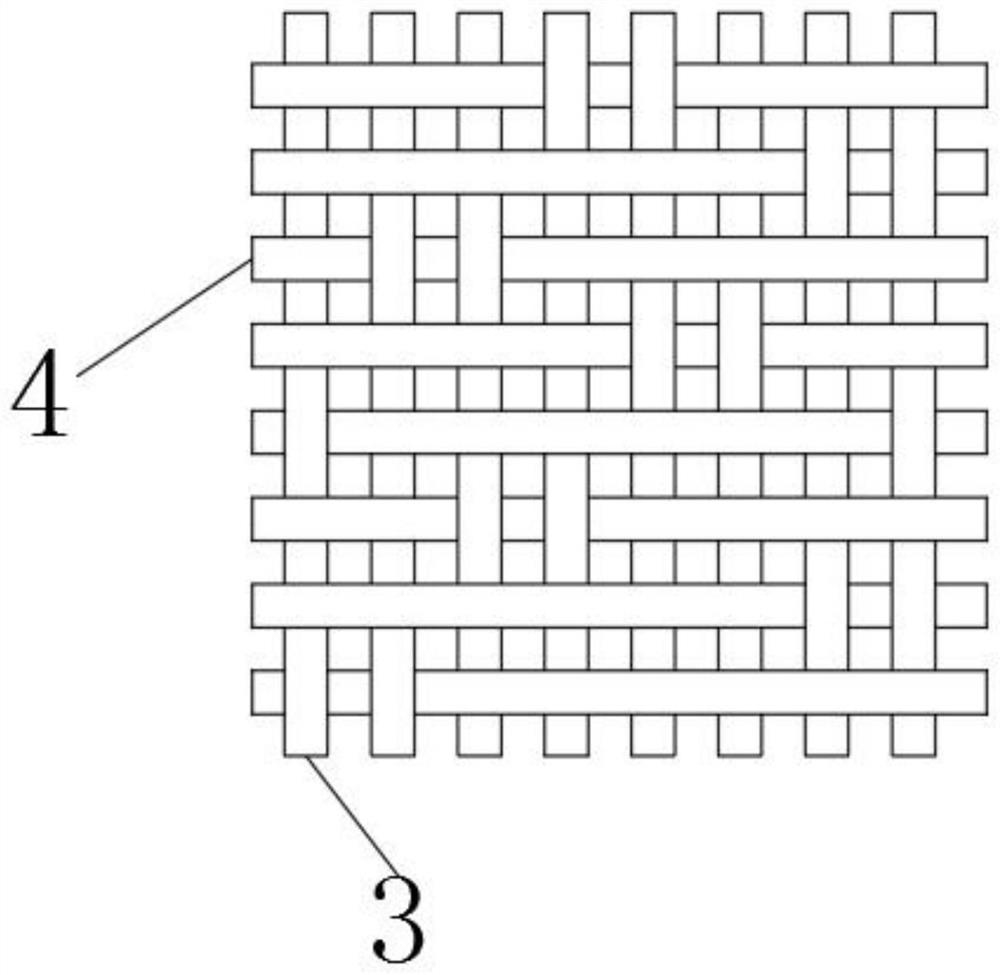

[0026] A glass fiber coated filter cloth, comprising a polytetrafluoroethylene film layer 1, a glass fiber layer 2, a glass fiber warp 3 and a glass fiber weft 4, the glass fiber layer 2 is connected to the bottom of the polytetrafluoroethylene film layer 1, the glass fiber The fiber layer 2 is woven from glass fiber warp threads 3 and glass fiber weft threads 4 .

[0027] The polytetrafluoroethylene film layer 1 is expanded polytetrafluoroethylene.

[0028] The thickness of the glass fiber layer 2 is greater than that of the polytetrafluoroethylene film layer 1, and the weaving process of the glass fiber warp 3 and the glass fiber weft 4 on the glass fiber layer 2 adopts a double twill weave process.

[0029] A kind of manufacture method of glass fiber membrane filter cloth, comprises the following steps:

[0030] (1) Preparation of glass fiber: wash the raw material with water, the water temperature is 10°C, until the surface of the raw material is free of impurities, and i...

Embodiment 2

[0036] A glass fiber coated filter cloth, comprising a polytetrafluoroethylene film layer 1, a glass fiber layer 2, a glass fiber warp 3 and a glass fiber weft 4, the glass fiber layer 2 is connected to the bottom of the polytetrafluoroethylene film layer 1, the glass fiber The fiber layer 2 is woven from glass fiber warp threads 3 and glass fiber weft threads 4 .

[0037] The polytetrafluoroethylene film layer 1 is expanded polytetrafluoroethylene.

[0038] The thickness of the glass fiber layer 2 is greater than that of the polytetrafluoroethylene film layer 1, and the weaving process of the glass fiber warp 3 and the glass fiber weft 4 on the glass fiber layer 2 adopts a double twill weave process.

[0039] A kind of manufacture method of glass fiber membrane filter cloth, comprises the following steps:

[0040] (1) Preparation of glass fiber: Wash the raw material with water at a temperature of 20°C until the surface of the raw material is free of impurities and then draw...

Embodiment 3

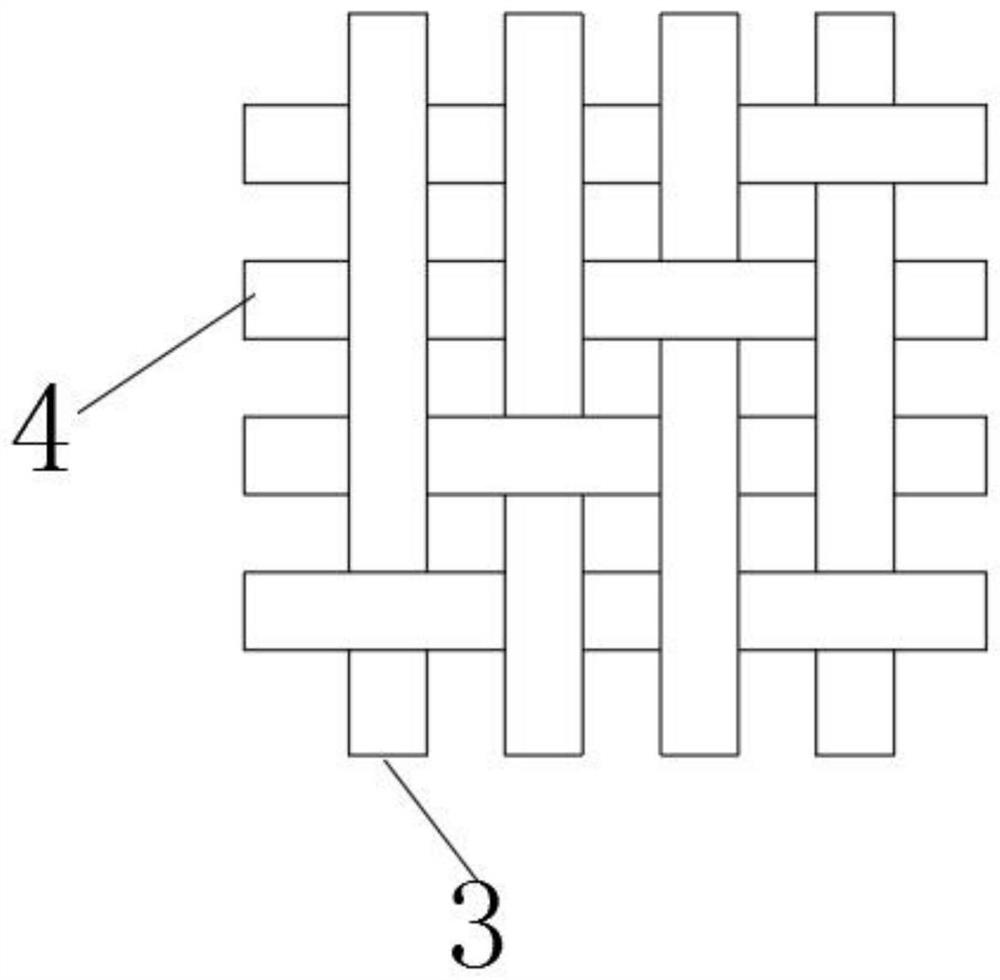

[0046] A glass fiber coated filter cloth, comprising a polytetrafluoroethylene film layer 1, a glass fiber layer 2, a glass fiber warp 3 and a glass fiber weft 4, the glass fiber layer 2 is connected to the bottom of the polytetrafluoroethylene film layer 1, the glass fiber The fiber layer 2 is woven from glass fiber warp threads 3 and glass fiber weft threads 4 .

[0047] The polytetrafluoroethylene film layer 1 is expanded polytetrafluoroethylene.

[0048] The thickness of the glass fiber layer 2 is greater than that of the polytetrafluoroethylene film layer 1, and the weaving process of the glass fiber warp 3 and the glass fiber weft 4 on the glass fiber layer 2 adopts a 1 / 3 twill weave process.

[0049] A kind of manufacture method of glass fiber membrane filter cloth, comprises the following steps:

[0050] (1) Preparation of glass fiber: wash the raw material with water, the water temperature is 15°C, until the surface of the raw material is free of impurities, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com