A manufacturing device and process for absorbing antibacterial nonwovens for medical protective clothing

A non-woven fabric and manufacturing device technology, applied in the direction of non-woven fabrics, lamination devices, textiles and papermaking, etc., can solve the problems of not having antibacterial adsorption function, complex production, surface structure modification process restrictions, etc. The effect of surface structure modification process limitation, high production efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

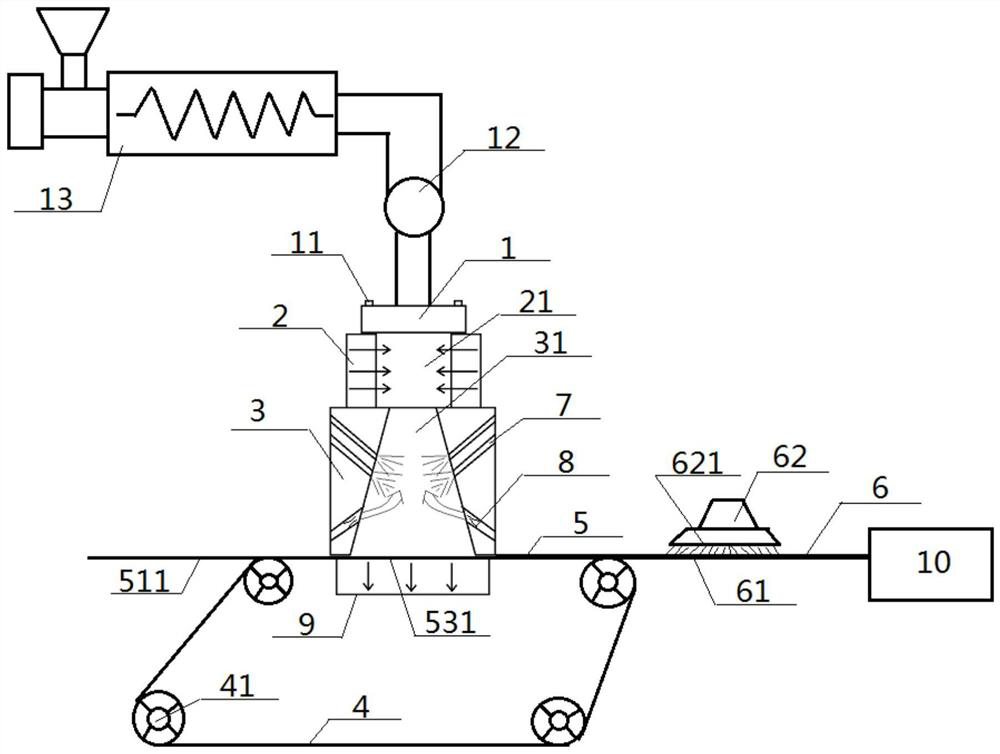

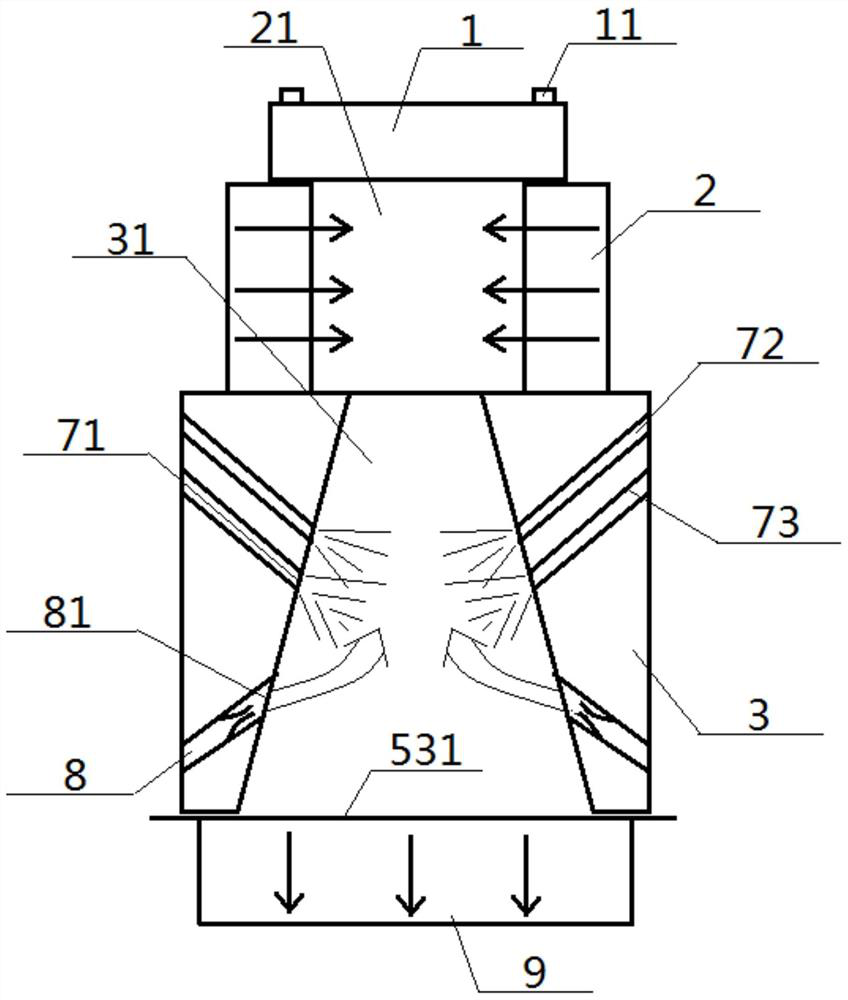

[0059] See Figure 1 — Figure 5 , a medical protective taking adsorption antibacterial nonwoven fabric production apparatus, comprising a spinneret 1, a side cooling device 2, a drafting device 3 and a conveyor belt 4, the side cooling device 2 is provided with a cooling chamber 21, the drawing device 3 is provided with a drawing chamber 31, the bottom of the wire spray plate 1 is sequentially through the cooling chamber 21, the drafting chamber 31 after the top of the conveyor belt 4 is communicated; the part on the conveyor belt 4 opposite the bottom of the drafting chamber 31 is the laying section 531, the upstream of the laying section 531 is the incoming section 511, Downstream of the laying section 531 is a film-forming section 61, the upper part of the film-forming segment 61 is provided with a yin mist sprayer 62, the shadow fog sprayer 62 is provided at the bottom of the cloud fog sprayer 621 and the film-forming section 61 is set up and down, the incoming section 511, th...

Embodiment 2

[0062] The basic content is the same as Example 1, the difference is that:

[0063] The cationic polyelectrolyte is sodium alginate, hyaluronic acid, polyacrylic acid, polystyrene sulfonic acid, polyethylene sulfonic acid, polyethylene phosphoric acid in any one or any mixture;

[0064] The anionic polyelectrolyte is polypropyl hydrochloride, chitosan, polydivinyldimethylammonium chloride, polyethyleneimide, polyquaternium salt, polyvinylpyridine in any one or any mixture.

Embodiment 3

[0066] The basic content is the same as Example 1, the difference is that:

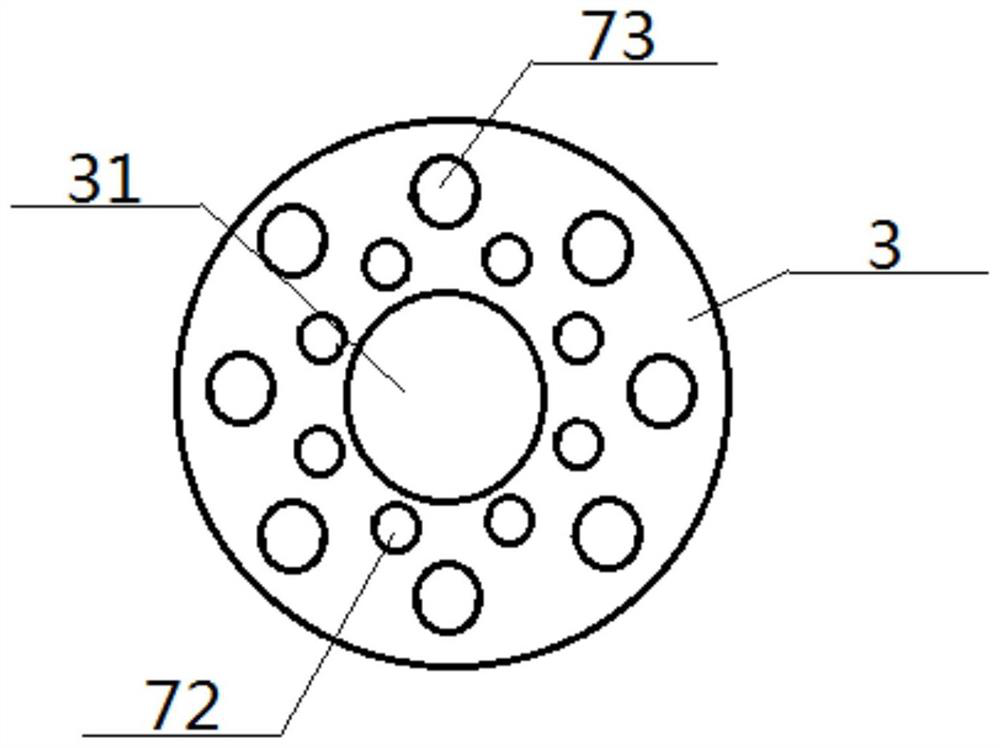

[0067] The oblique spray pipe 7 includes a diagonal spray executive 72 and an oblique spray low tube 73, the oblique spray executive 72 is higher than the oblique spray low pipe 73 is set, the number of the oblique spray executive 72 is at least two, the number of the oblique spray low pipe 73 is also at least two. Adjacent diagonal spray executive 72, oblique spray low tube 73 are parallel to each other. The diameter of the oblique spray executive 72 is less than the diameter of the oblique spray low pipe 73, all the oblique spray executive 72 is uniformly arranged along the same circumference, and all the diagonal spray low tube 73 is uniformly arranged along the same circumference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com