Method for producing ultra-pure ferritic stainless steel through continuous rolling and annealing

A technology of ultra-pure iron and stainless steel, which is applied in the field of metal processing, can solve the problems that the product requirements cannot be met, and the mechanical properties and plastic strain ratio of ultra-pure ferrite cannot meet the requirements of customers, so as to improve the mechanical properties and increase the R value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

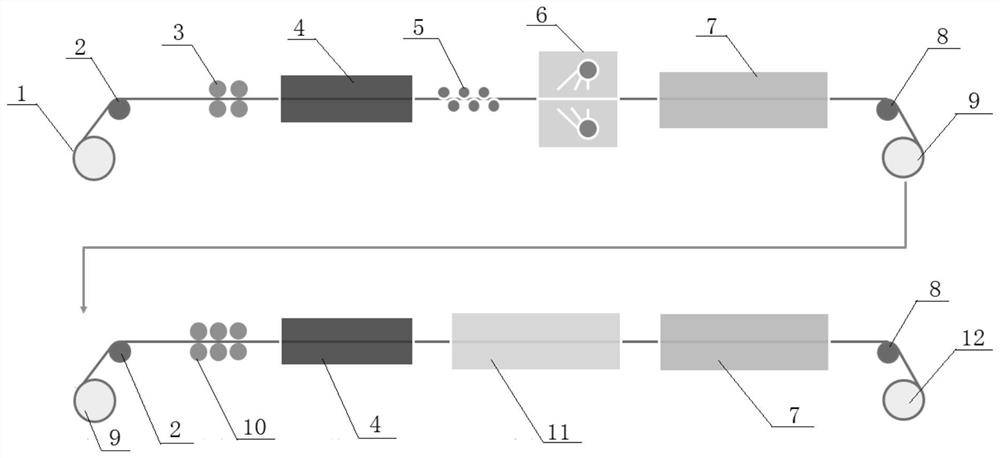

[0019] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings. The following description is only for explaining the present invention, and does not limit its content.

[0020] A method for continuous rolling and annealing to produce ultra-pure ferritic stainless steel, the specific method comprising:

[0021] The hot-rolled black skin is firstly rolled two times, annealed and pickled to obtain a 2E surface product, and then three times rolled, annealed and pickled to obtain an ultra-pure ferritic stainless steel strip product with a 2B / 2D surface ;

[0022] After each rolling, rapidly heat from room temperature to 900-1100°C, and immediately water-cool to room temperature (ie solution treatment); the time for rapid heating from room temperature to 900-1100°C t≤10min.

[0023] The total reduction of the two rolling passes is ≥ 20%.

[0024] The total rolling reduction of the three rolling passes is more th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic strain ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com