Local heat treatment method after repair welding of inner wall of large quenched and tempered steel pressure vessel

A local heat treatment and pressure vessel technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as stress corrosion failure, equipment safety operation threat, improper temperature gradient, etc., to reduce residual stress and avoid sensitization cracks , to ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

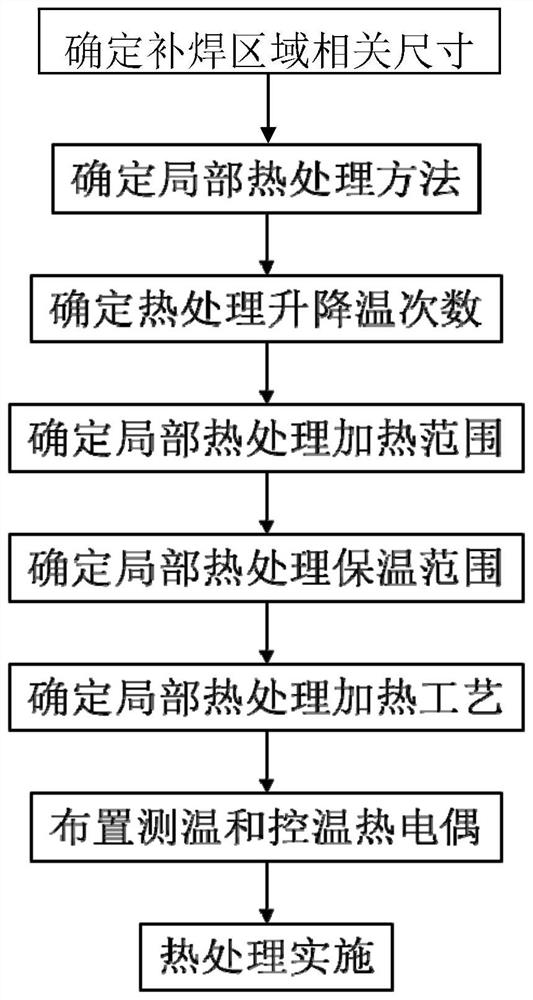

Method used

Image

Examples

Embodiment 1

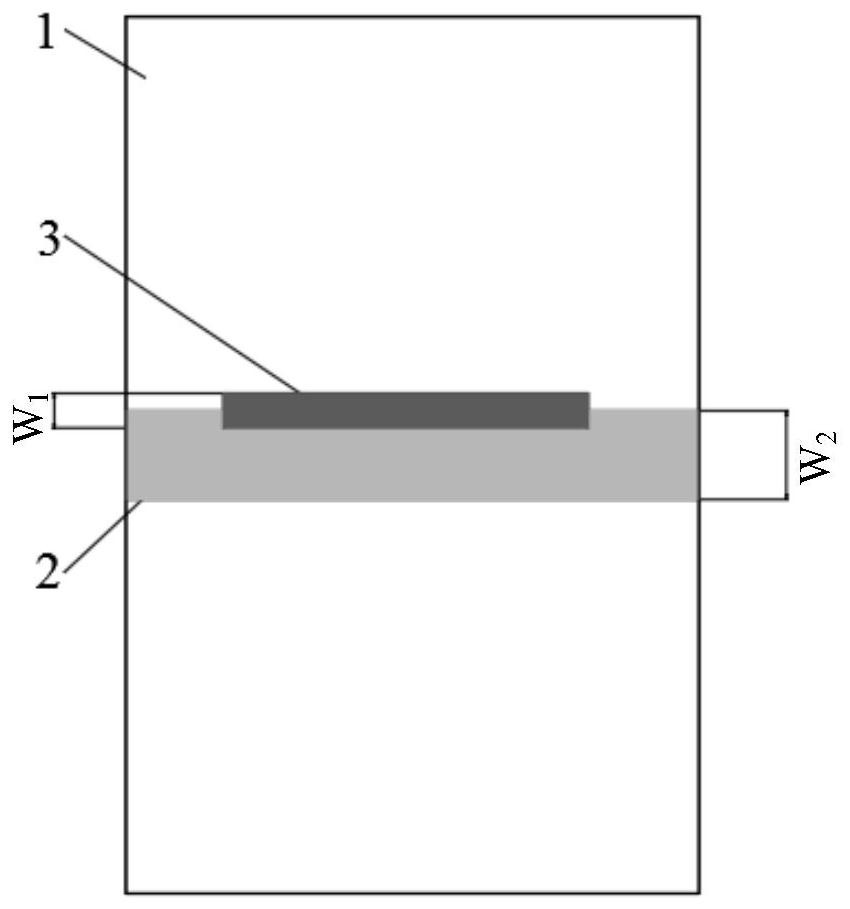

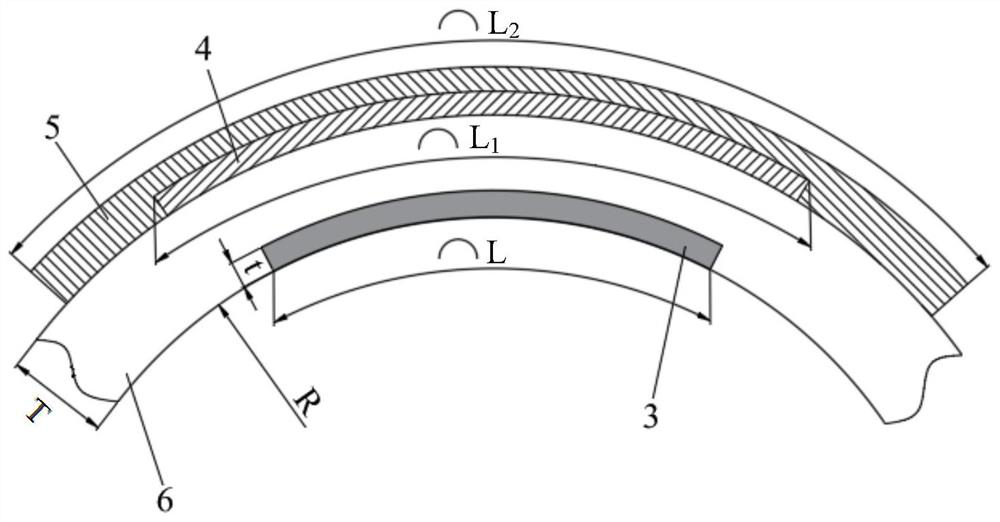

[0057] In this embodiment, two cylinders with a material of 12Cr2Mo1V, a diameter of 1m and a wall thickness of 130mm are selected. Submerged arc welding is used to weld the two cylinders together. The width of the inner wall weld is 10mm. After the welding is completed, the overall heat treatment in the furnace is performed. After heat treatment, a defect with a length of 20mm is processed in the girth weld on the inner wall of the cylinder, and then the defect is repaired by manual arc welding. The length of the repair welding seam is 26mm, and the width of the repair welding seam is 10mm. After the repair welding, the residual stress on the surface of the repair welding seam was tested by the indentation strain method.

[0058] After repair welding, the residual stress in the weld area increases. In order to eliminate the residual stress after repair welding, the local heat treatment method after repair welding of the inner wall of a large quenched and tempered steel pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com