Capacitor carbon and preparation method thereof

A capacitance carbon and specific capacitance technology, applied in the field of capacitance carbon, can solve the problems of high cost, long operation process, and long preparation process route, and achieve the effects of low cost, simplified process flow, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

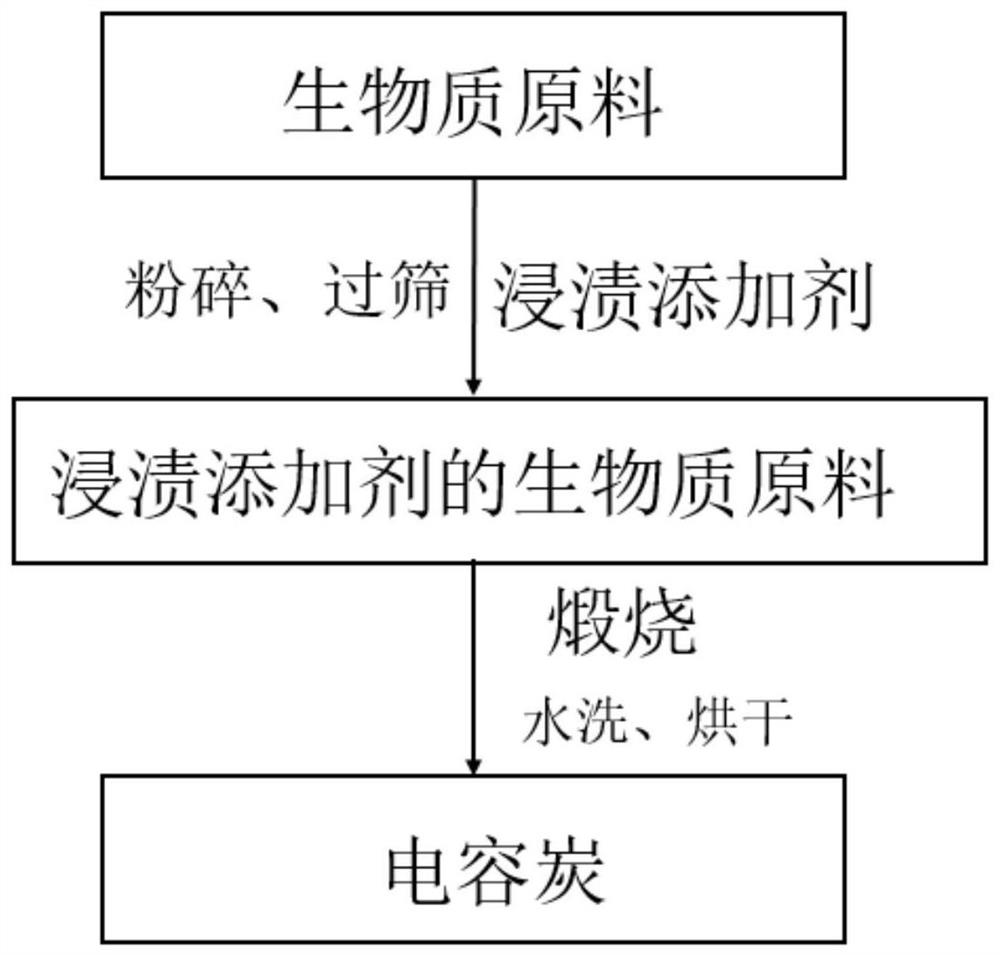

[0041] The main technological process of the preparation method of the capacitance carbon that the embodiment of the present invention proposes is as follows figure 1 As shown, it mainly includes impregnating additives and calcining steps; the specific steps are as follows:

[0042] 1) Clean the biomass raw material.

[0043] The biomass raw material of the present invention mainly uses agricultural and forestry waste biomass, preferably corn leaves, straw, rice husks, and fruit husks, but not limited thereto.

[0044] 2) Step of impregnating additives: crushing and sieving the cleaned biomass raw materials, then immersing them in the additive solution for impregnation treatment, and then drying the impregnated biomass raw materials to obtain the biomass impregnated with additives raw material.

[0045]Wherein, the additive is selected from one or both of ammonium dihydrogen phosphate and diammonium hydrogen phosphate. The mass ratio of the biomass raw material to the addit...

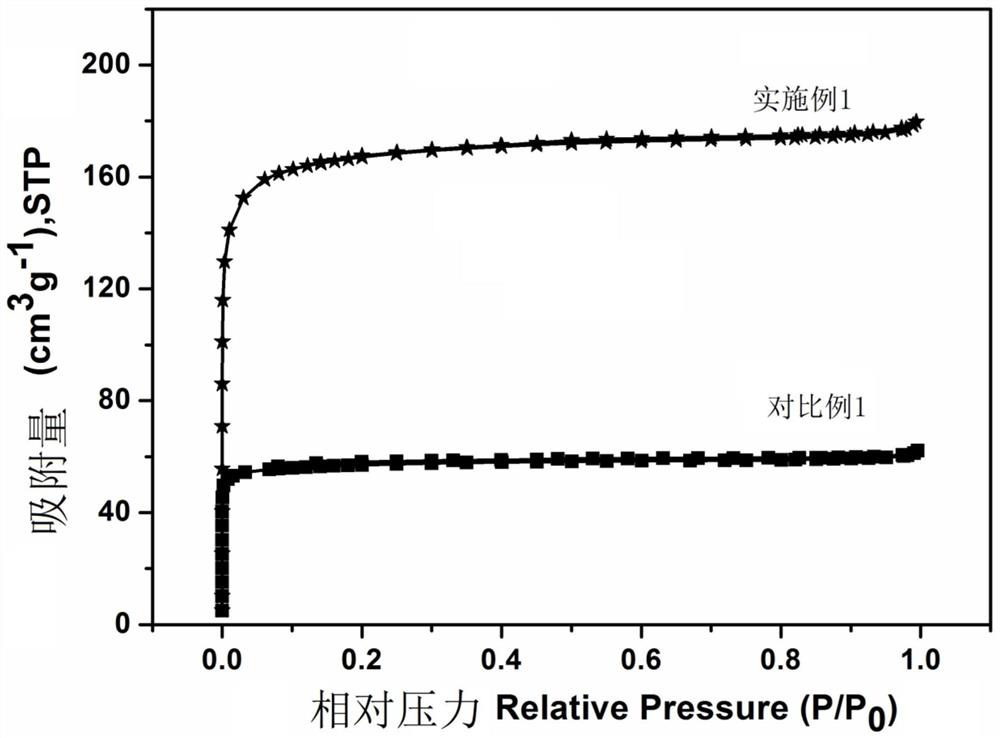

Embodiment 1

[0056] The present embodiment prepares a kind of capacitor carbon, and specific preparation steps are as follows:

[0057] 1) Cleaning: clean and dry the biomass raw material corn leaves.

[0058] 2) Impregnating additives: crush the corn leaves cleaned in step 1), and then pass through a 60-mesh sieve. Get 10g of sieved corn leaf particles and soak them in the diammonium hydrogen phosphate solution (wherein the mass ratio of corn leaves and diammonium hydrogen phosphate is 1:2; the water content in the diammonium hydrogen phosphate solution ensures that the diammonium hydrogen phosphate solution can immerse corn leaves), stirring and impregnating for 6 hours and then drying to obtain corn leaves impregnated with diammonium hydrogen phosphate.

[0059] 3) Calcination (carbon fixation-carbonization-activation-doping): put the corn leaves impregnated with diammonium hydrogen phosphate into a tube furnace, and calcinate under nitrogen atmosphere; specifically, firstly, at a heat...

Embodiment 2

[0061] This example prepares a capacitor carbon. Compared with example 1, this example differs from step 2), and other steps are the same. Wherein, step 2) of the present embodiment is specifically as follows:

[0062] 2) Impregnating additives: crush the corn leaves cleaned in step 1), and then pass through a 60-mesh sieve. Get 10g of sieved corn leaf and soak in the diammonium hydrogen phosphate solution (wherein, the mass ratio of corn leaf and diammonium hydrogen phosphate is 1:0.1; the water content in the diammonium hydrogen phosphate solution ensures that the diammonium hydrogen phosphate solution can Just immerse the corn leaves), stir and impregnate for 12 hours and then dry to obtain corn leaves impregnated with diammonium hydrogen phosphate.

[0063] The other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com