Intelligent overflow waste recovery device for injection mold

A technology for injection molds and recovery devices, which is applied in the field of intelligent recovery devices for overflowing waste materials for injection molds, which can solve problems such as increased labor costs, environmental pollution, and inconvenient operations for operators, and achieve the effects of reducing wear, avoiding splashing, and uniform magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

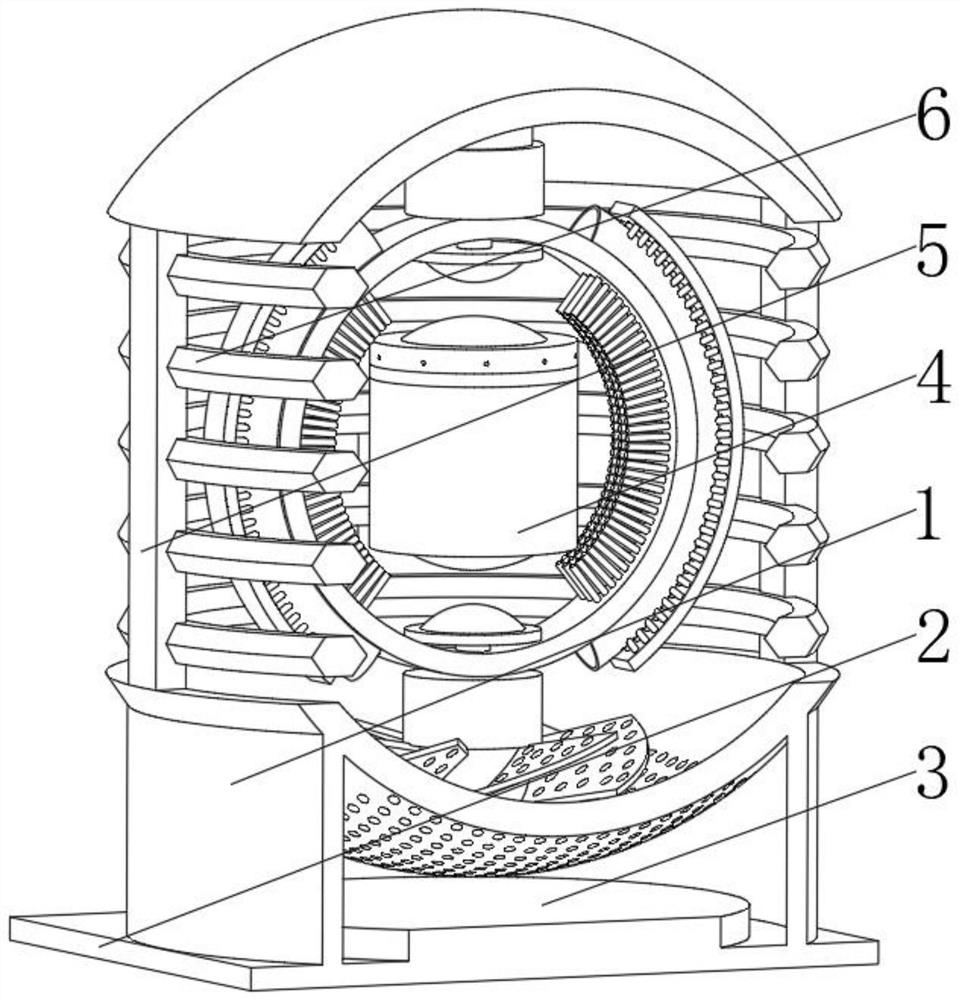

[0039] see Figure 1-2 , the present invention provides a technical solution: an intelligent recovery device for overflowing waste materials for injection molds, specifically comprising:

[0040] Protective seat 1, the protective seat 1 has a seat column, and a seat plate 2 fixed on the bottom of the seat column, and an airflow fan 3 fixed on the top of the seat plate 2 and located in the inner cavity of the seat column; by designing the airflow fan 3, the overall equipment The components are promoted by the air flow, and the components are cooled by the air flow to protect the components themselves. At the same time, the overflow waste of the injection mold is condensed and solidified to prevent the injection materials from overflowing and bonding with the components, so that the components stick to each other. It will affect the subsequent processing process and make it more difficult to clean up.

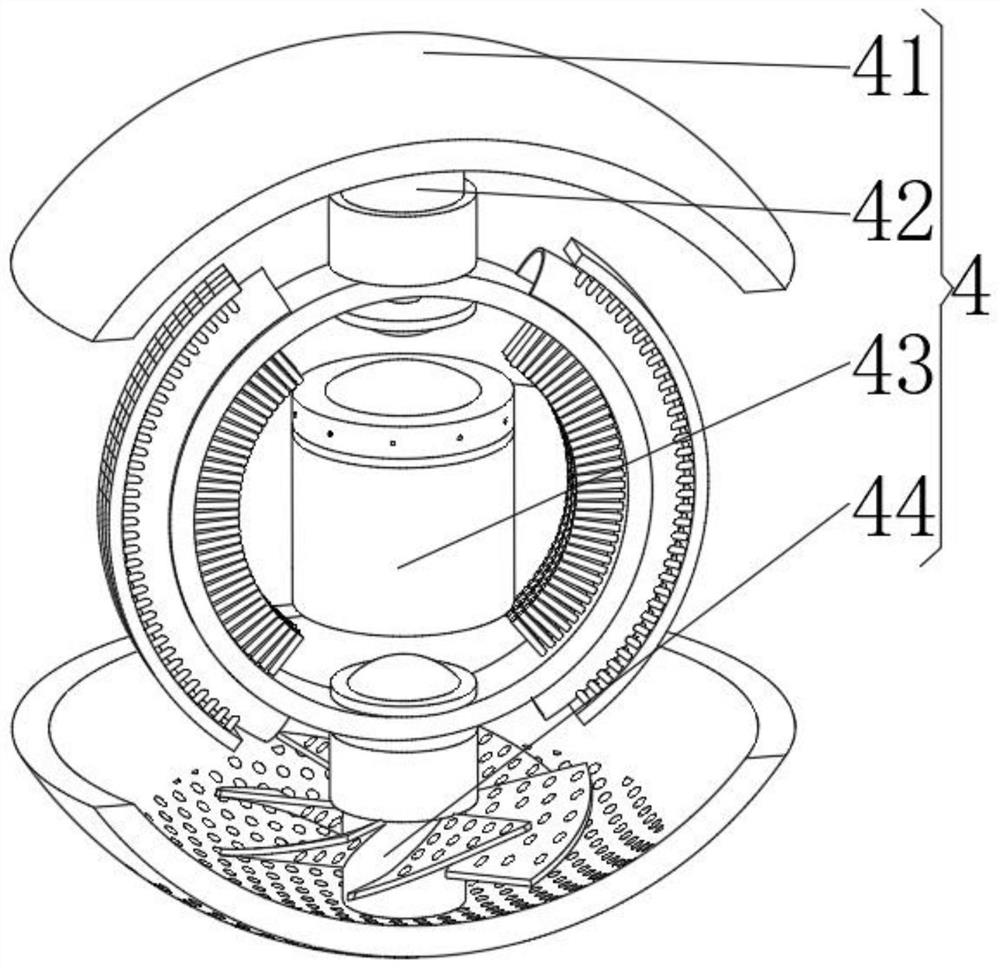

[0041] Waste material recovery mechanism 4, this waste material recovery me...

Embodiment 2

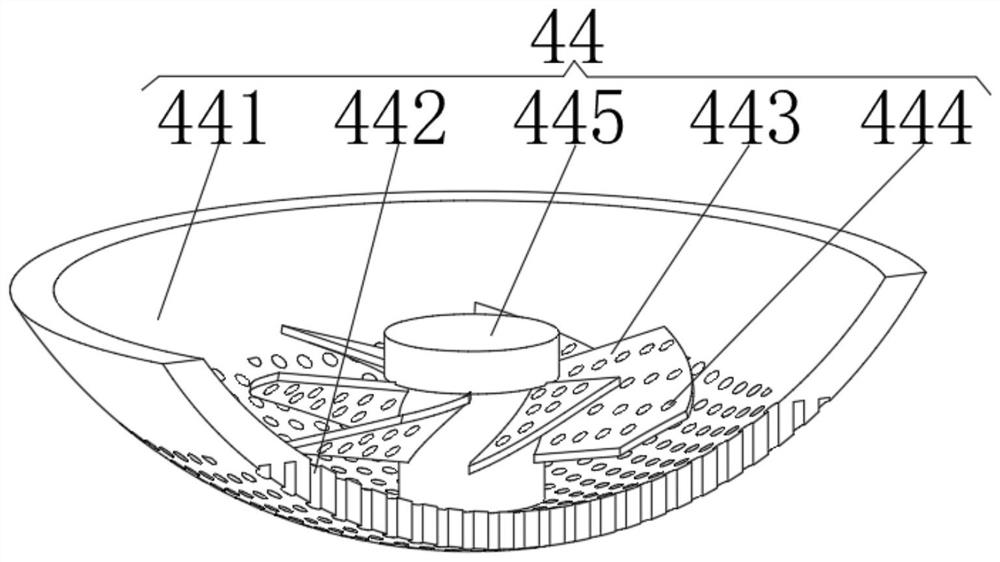

[0045] see Figure 1-3 On the basis of Embodiment 1, the present invention provides a technical solution: the transmission mechanism 44 includes:

[0046] An isolation base plate 441, the isolation base plate 441 has a main board body, and a filter air hole 442 provided on the surface of the main board body;

[0047] The airflow blade 443 has a slanted plate, a through hole 444 opened on the surface of the slanted plate, and a T-shaped rotating column 445 installed on the inner surface of the slanted plate. The airflow is guided by the airflow fan blade 443, and the mass inertia of the airflow fan blade 443 itself strengthens its movement, and the airflow is gathered and flowed. The arc of the airflow fan blade 443 itself impacts and guides the overflowing waste and slows down the flow, avoiding the generation of overflowing waste. splash.

[0048] The bottom of the isolation bottom plate 441 is connected to the protection seat 1, and the top of the T-shaped rotating column ...

Embodiment 3

[0051] see Figure 1-4 , On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the recovery mechanism 43 includes:

[0052] The overflow cleaning mechanism 431, the overflow cleaning mechanism 431 has an annular main body, and a clamping cylinder 432 installed on the top and bottom of the annular main body, and a force applying disc 433 fixed on the bottom of the clamping cylinder 432, and is arranged on the clamping cylinder 432 The spherical contact block 434 on the other side of the force plate 433;

[0053] Shaping lower mold 435, this molding lower mold 435 has a molding cavity, and the molding upper mold 436 that is arranged on the inner surface of the molding cavity, and is installed on the molding lower mold 435 and molding upper mold 436 away from each other The spherical surface of the side is against the block 437 . Through the spherical surface design of the spherical contact block 434 and the spherical contact block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com