Curable composition

A composition, polymer technology, applied in the field of curable composition, can solve problems such as hindering effective dynamic vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

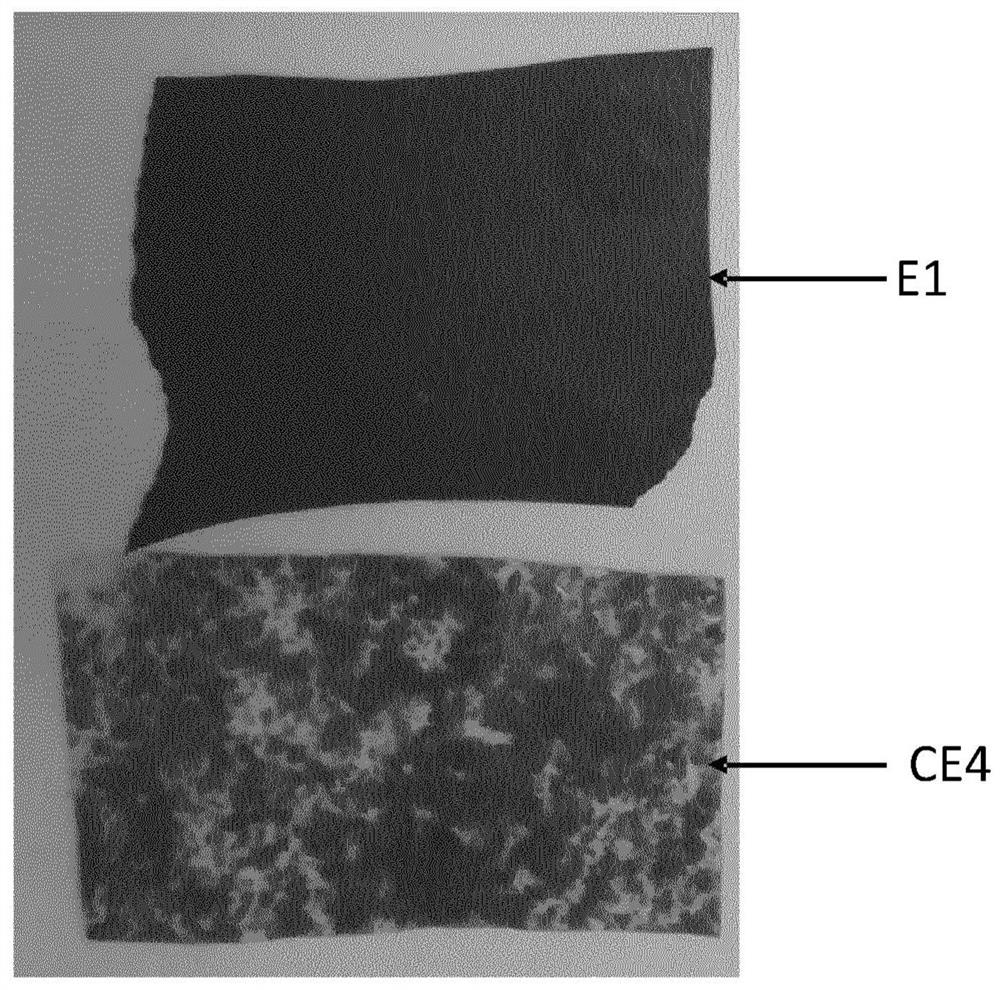

[0092] In a first embodiment, said at least one polymer (E) is a (per)fluoroelastomer. For the sake of brevity, the (per)fluoroelastomer is also referred to as elastomer (E1).

[0093] As stated, the elastomer (E1) may, in addition to recurring units derived from at least one (per)fluorinated monomer (F) selected from the group mentioned above, also comprise (M) repeating unit. Examples of hydrogenated monomers (M) are notably hydrogenated alpha-olefins including ethylene, propylene, 1-butene, diene monomers, styrene monomers, alpha-olefins are typically used.

[0094] Preferably, the elastomer (E1) is selected from:

[0095] (1) Copolymers based on VDF, wherein VDF is copolymerized with at least one additional comonomer selected from the group consisting of:

[0096] (a)C 2 -C 8 Perfluoroolefins, such as tetrafluoroethylene (TFE), hexafluoropropylene (HFP);

[0097] (b) C containing hydrogen 2 -C 8 Olefins, such as vinyl fluoride (VF), trifluoroethylene (TrFE), hexafluo...

no. 2 example

[0138] In a second embodiment, said at least one polymer (E) is a thermoplastic (per)fluoropolymer. For the sake of clarity, the thermoplastic material is also referred to below as thermoplastic material (E2).

[0139] As stated, the thermoplastic material (E2) may additionally comprise, in addition to recurring units derived from at least one (per)fluorinated monomer (F) selected from the group mentioned above, derived from at least one hydrogenated monomer Repeating units of (M), the hydrogenated monomer is preferably selected from:

[0140] - ethylene;

[0141] - Acrylic monomers having the general formula: CH 2 =CH-CO-O-R 2 , where R 2 is C optionally containing one or more heteroatoms 1 -C 20 hydrocarbon group;

[0142] - Vinyl ether monomers having the general formula: CH 2 =CH-O-R 2 , where R 2 is C optionally containing one or more heteroatoms 1 -C 20 hydrocarbon group;

[0143] - Vinyl esters of carboxylic acids having the general formula: CH 2 =CH-O-CO-...

Synthetic example

[0228] Synthesis of Master Batch A

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com