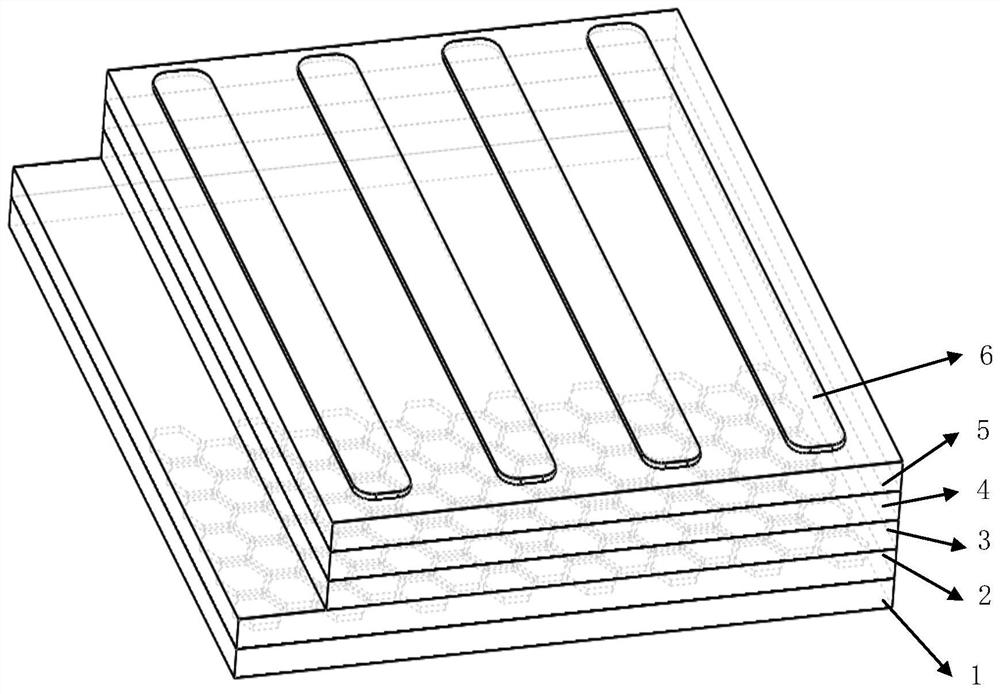

Flexible perovskite solar cell with high power mass ratio and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as spontaneous curling of ultra-thin films, and achieve the effects of improved photoelectric conversion efficiency, low manufacturing cost, and small quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0033] (1) Immerse the glass substrate in detergent for ultrasonic cleaning, then rinse off the detergent with deionized water, and then immerse it in deionized water, acetone and isopropanol for ultrasonic cleaning.

[0034] (2) Deposit a Parylene-C thin film on a glass substrate with a thickness of 2 μm.

[0035] (3) The surface roughness of the Parylene film is improved by using ion beam polishing technology, and the surface roughness of the film surface is controlled below 8nm.

[0036] (4) Coating a Ni metal layer on the surface of the polished Parylene-C film with a thickness of 200nm.

[0037] (5) Spin-coat photoresist on the Ni metal layer, perform photolithography after pre-baking and curing.

[0038] (6) Obtain the grid pattern formed by the photoresist by developing after photolithography.

[0039](7) Remove unnecessary metal parts by wet etching to form a conductive metal grid.

[0040] (8) Wash away the photoresist.

[0041] (9) Sputter a layer of ITO with a t...

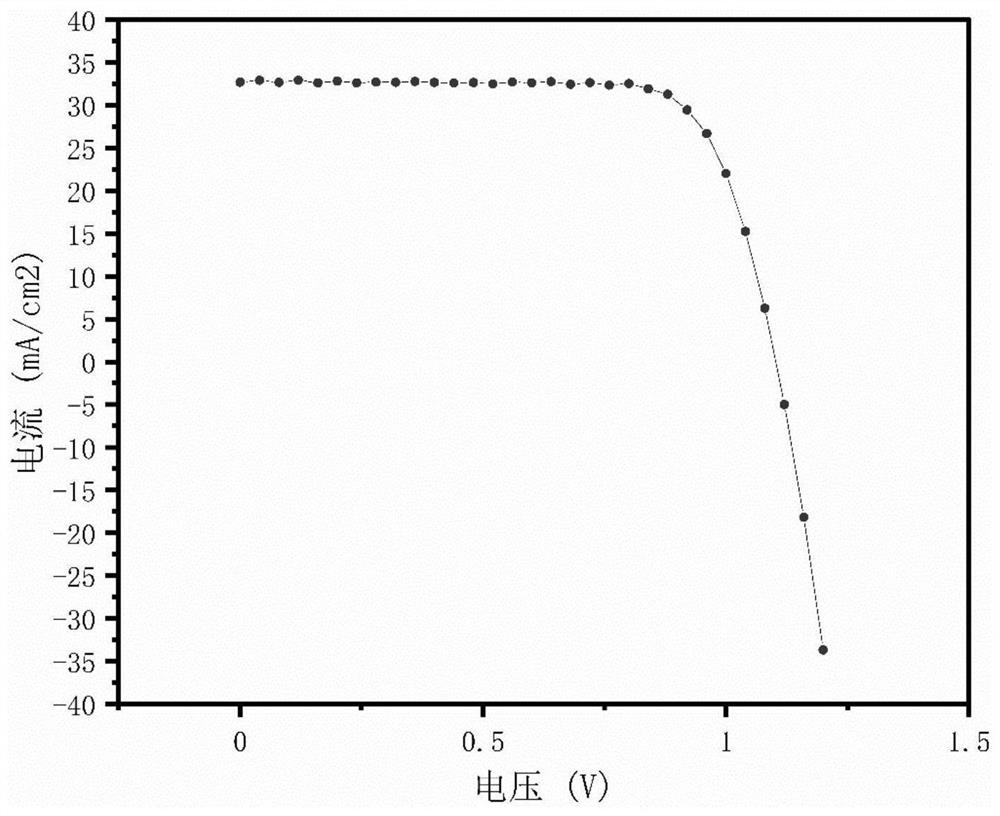

Embodiment example 2

[0048] (1) Immerse the glass substrate in detergent for ultrasonic cleaning, then rinse off the detergent with deionized water, and then immerse it in deionized water, acetone and isopropanol for ultrasonic cleaning.

[0049] (2) Deposit a Parylene-C thin film on a glass substrate with a thickness of 2 μm.

[0050] (3) The surface roughness of the Parylene film is improved by using ion beam polishing technology, and the surface roughness of the film surface is controlled below 8nm.

[0051] (4) Coating a Ni metal layer on the surface of the polished Parylene-C film with a thickness of 200nm.

[0052] (5) Spin-coat photoresist on the Ni metal layer, perform photolithography after pre-baking and curing.

[0053] (6) Obtain the grid pattern formed by the photoresist by developing after photolithography.

[0054] (7) Remove unnecessary metal parts by wet etching to form a conductive metal grid.

[0055] (8) Wash away the photoresist.

[0056] (9) Sputter a layer of ITO with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com