Novel engine

An engine, a new type of technology, applied in the direction of machines/engines, hot gas variable displacement engine devices, mechanical equipment, etc., can solve the problems of low conversion efficiency, low work efficiency and pollution, and the engine is easy to pollute the environment, so as to achieve low operating cost and structure Simple, low-polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

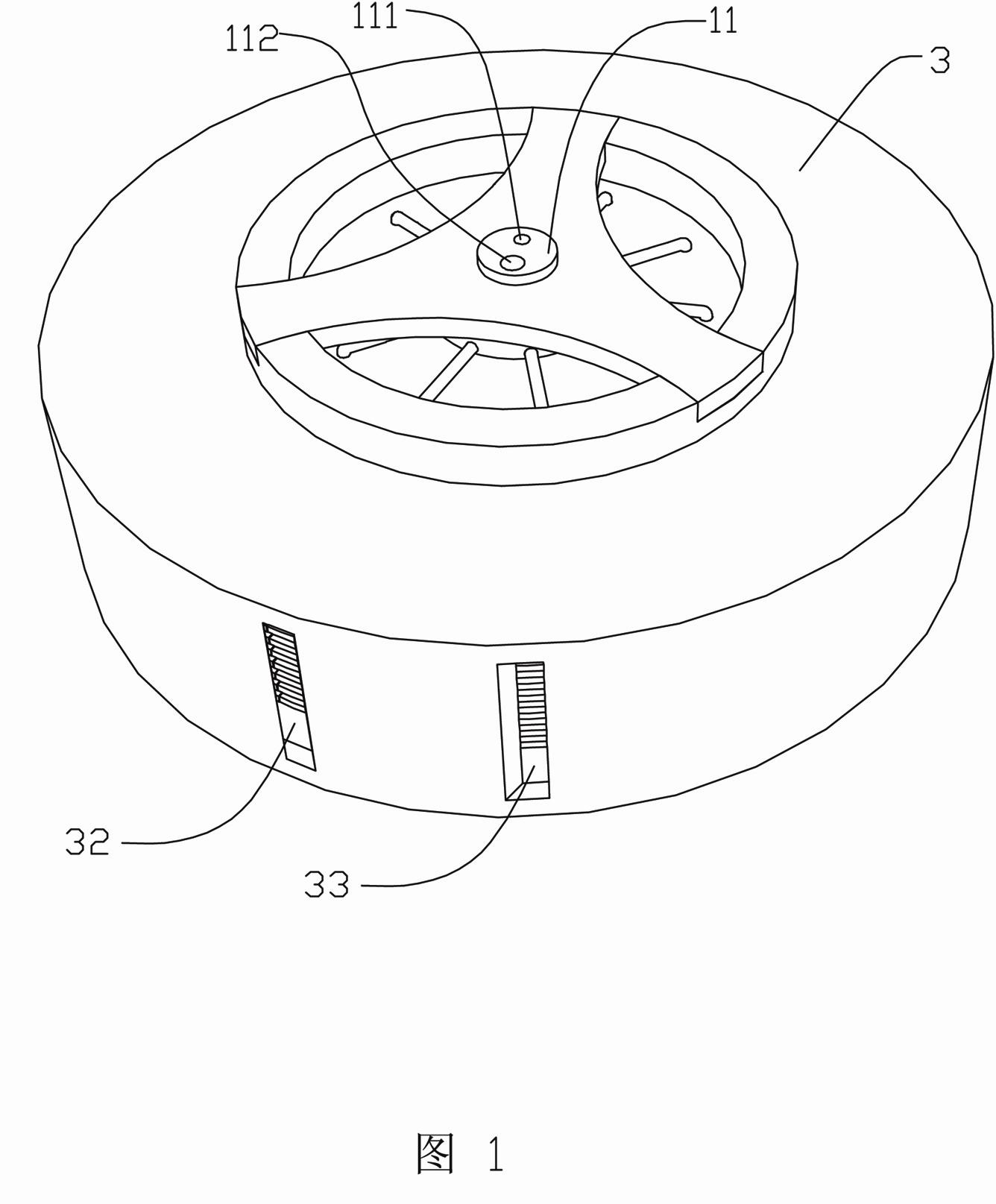

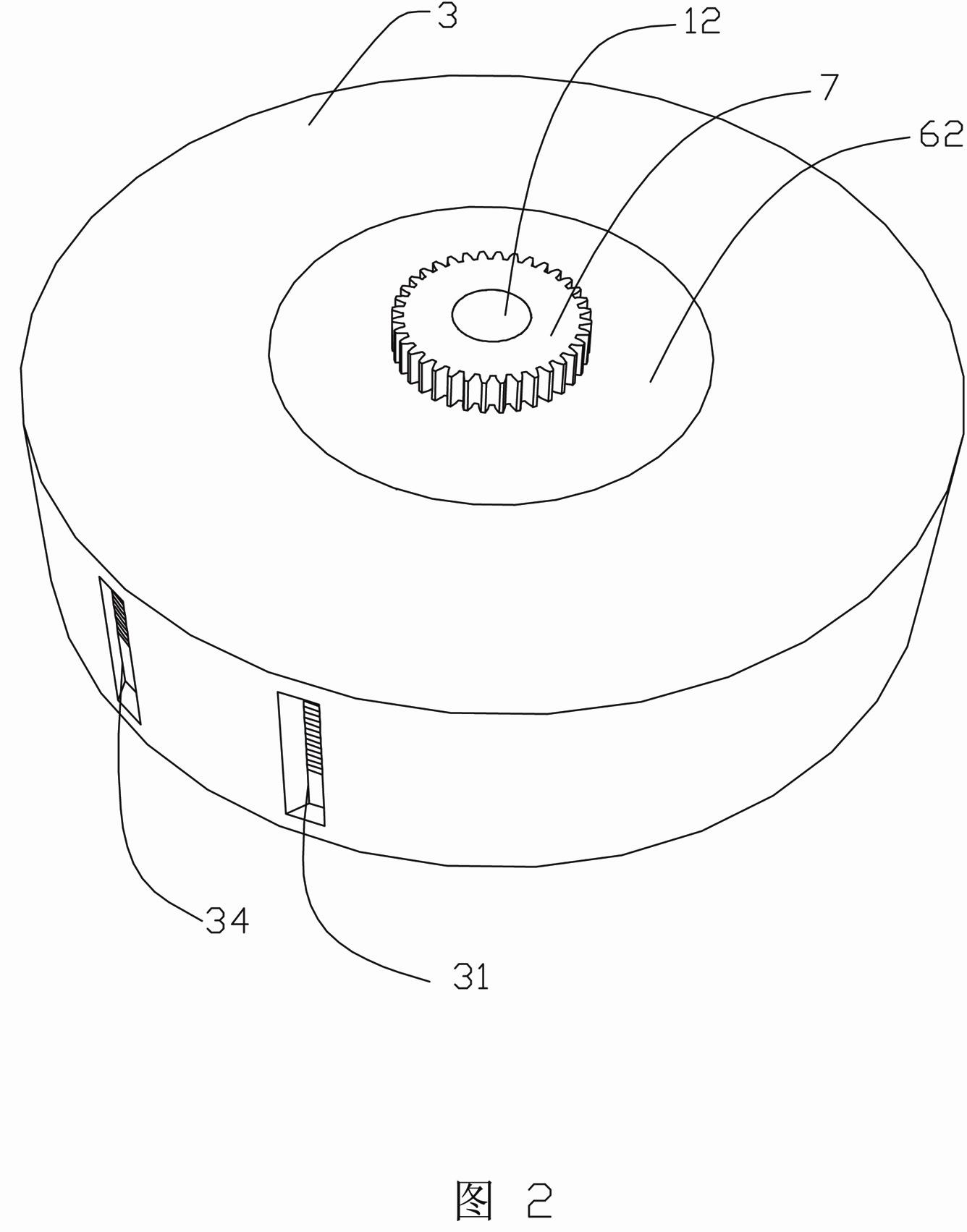

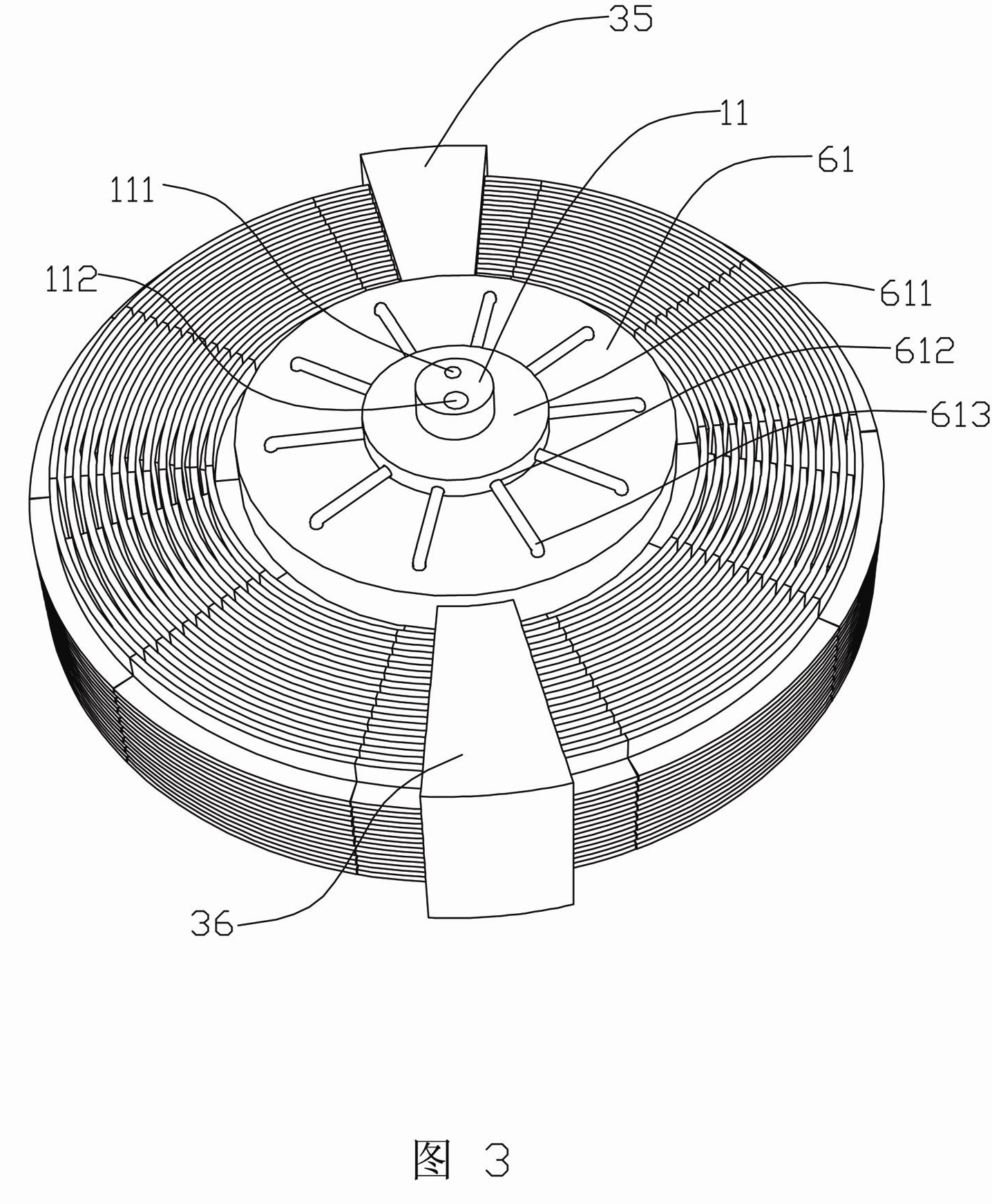

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7Shown, a kind of novel engine comprises two shaft rods 11,12 which are arranged on the central axis and are symmetrical up and down, a plurality of cylinders 2 which are evenly distributed around the shaft rods 11,12 and rotate around the shaft rods 11,12, and are arranged on the cylinder The piston 21 in 2 and the casing 3 that surrounds the cylinder 2 and is rotatably connected with the cylinder 2, the casing 3 is connected with the shaft rod 11; the piston 21 is provided with a piston rod 211, and the piston rod 211 is connected with two symmetrical shafts up and down. The connection blocks 41, 42 whose center deviates from the above-mentioned central axis, the connection blocks 41, 42 are rotatably connected with the piston rod 211; the connection points of the connection blocks 41, 42 and the piston rod 211 are symmetrical about the axis of the connection blocks 41, 42, The...

Embodiment 2

[0048] refer to Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 . A new type of engine, which is arranged on the central axis and has two symmetrical shafts 11, 12 up and down, a plurality of cylinders 2 evenly distributed around the two shafts, a piston 21 arranged in the cylinder 2, and a cylinder that can be wound around the cylinder 2 2 connected housing 3, the housing 3 is connected with the shaft rod 12; the piston 21 is provided with a piston rod 211, and the piston rod 211 is connected with two connection blocks 41, 42 which are symmetrical up and down and whose axes deviate from the above-mentioned central axis. The blocks 41, 42 are rotatably connected to the piston rod 211, and the connection points between the connecting blocks 41, 42 and the piston rod 211 are symmetrical about the axis of the connecting blocks 41, 42, and the axis of the connecting block 41 is connected to the shaft 11 through the connecting part 51 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com