Method for preparing high-melting-point metal ternary diffusion couple

A high-melting-point metal, diffusion couple technology, applied in testing metals, testing metal structures, solid-state diffusion coatings, etc., can solve the problems of solid diffusion and solid-liquid diffusion, and achieve high success rate, easy control of the preparation process, and good results. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

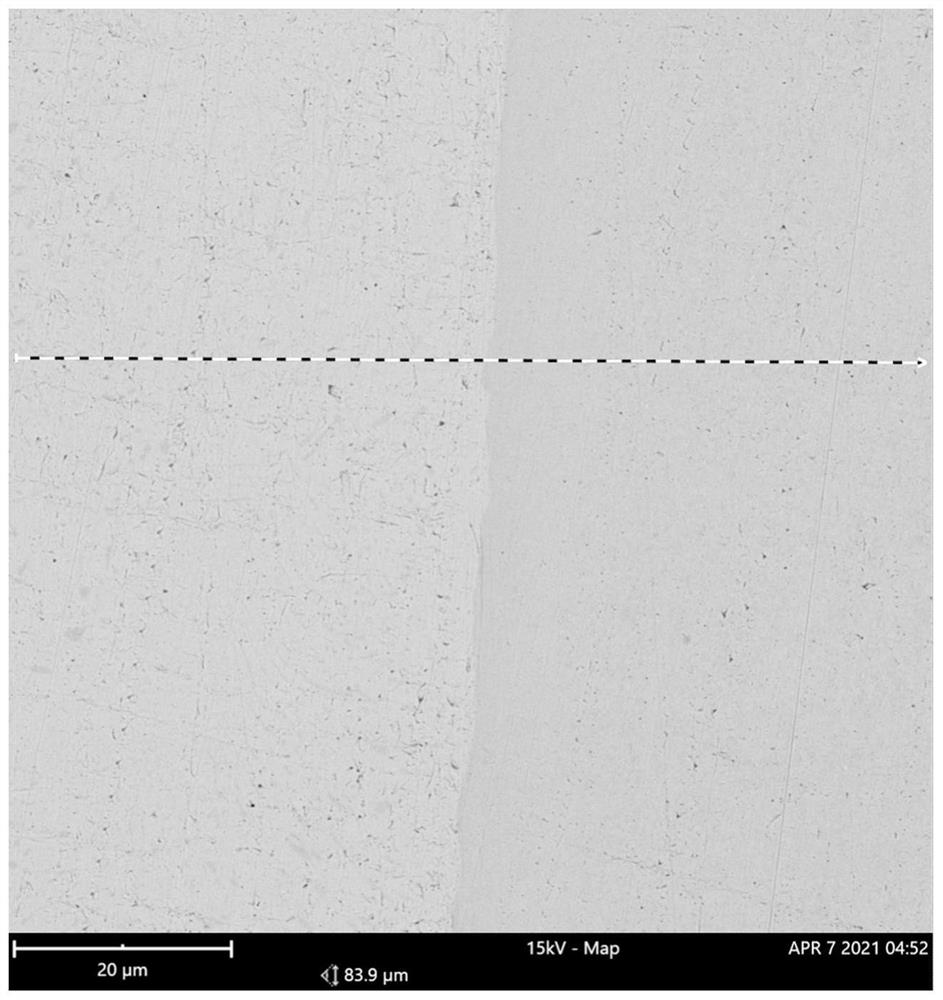

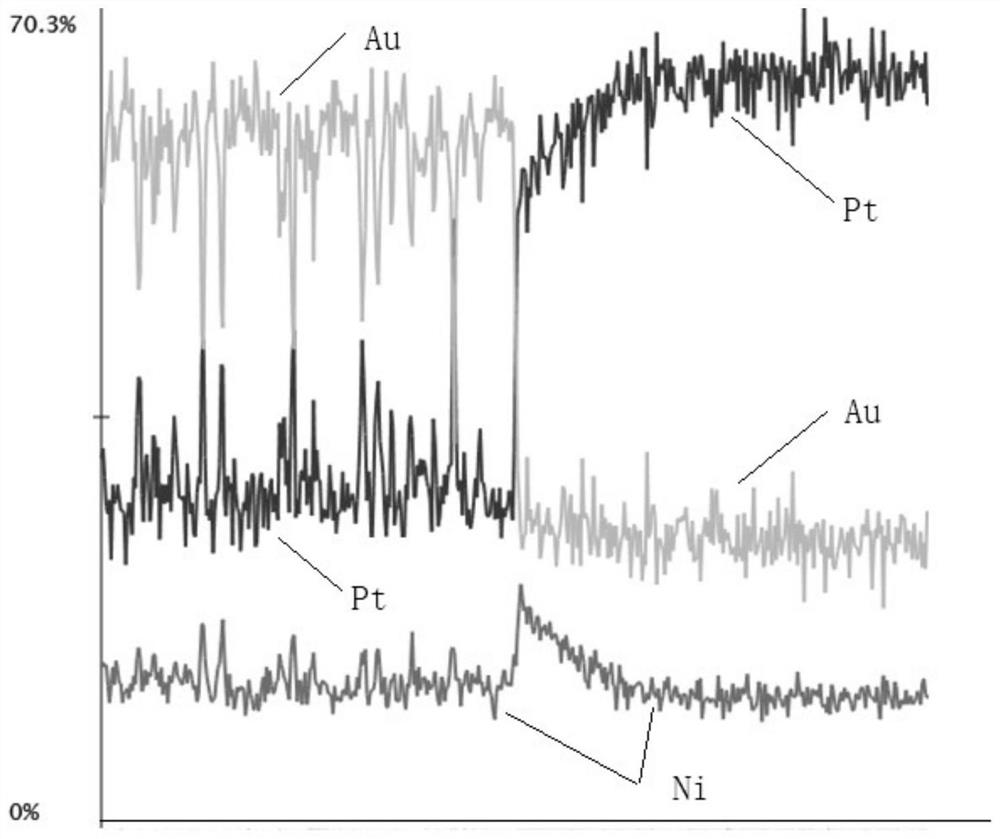

[0028] (1) Among the three high-melting-point metals of Pt, Au, and Ni, the Au metal block or sheet with the lowest melting point is laid on top of the Pt metal block with the highest melting point, and put into the corundum boat;

[0029] (2) Put the corundum boat into a high-temperature tube furnace, heat it up to 1100°C under the protection of argon, and keep it warm for 30 minutes, so that the Au is evenly melted and covered the surface of the Pt block, then lower the temperature to 900°C, and keep it warm for 120 hours , and then take it out after cooling to room temperature with the furnace;

[0030] (3) The surface of a Ni metal sheet with a thickness of 0.4 mm was ground and polished, and then bent and coated on the Au-Pt bonding interface, fixed with a clamp, vacuum-packed in a quartz tube, and annealed at 900 ° C;

[0031] (4) After the heat treatment is completed, the quartz tube is taken out and rapidly cooled in cold water, and then the prepared diffusion couple i...

Embodiment 2

[0034] (1) Among the three high-melting point metals Pt, Pd, and Cu, the Cu metal block or sheet with the lowest melting point is laid on top of the Pt metal block with the highest melting point, and put into the corundum boat;

[0035] (2) Put the corundum boat into a high-temperature tube furnace, heat it up to 1120°C under the protection of argon, and keep it warm for 30 minutes to let Cu evenly melt and cover the surface of the Pt block, then lower the temperature to 800°C, and keep it warm for 120 hours , and then take out after cooling with the furnace;

[0036] (3) The surface of the Pd metal sheet with a thickness of 0.5 mm was ground and polished, and then bent and coated on the Pt-Cu bonding interface, fixed with a clamp, vacuum-packed in a quartz tube, and diffusion annealed at 800 ° C;

[0037] (4) After the annealing is completed, the quartz tube is taken out and rapidly cooled in cold water, and then the prepared diffusion couple is taken out from the quartz tube...

Embodiment 3

[0039] (1) Among the three high-melting-point metals Pd, Ag, and Pt, the Ag metal block or sheet with the lowest melting point is laid on top of the Pt metal block with the highest melting point, and put into the corundum boat;

[0040] (2) Put the corundum boat into a high-temperature tube furnace, heat it up to 1000°C under the protection of argon, and keep it warm for 30 minutes to allow the Ag to evenly melt and cover the surface of the Pt block, then cool it down to 750°C and keep it warm for 120 hours , and then take out after cooling with the furnace;

[0041] (3) The surface of the Pd metal sheet with a thickness of 0.5 mm was ground and polished, and then bent and coated on the Ag-Pt bonding interface, fixed with a clamp, vacuum-packed in a quartz tube, and diffusion annealed at 750 ° C;

[0042] (4) After the annealing is completed, the quartz tube is taken out and rapidly cooled in cold water, and then the prepared diffusion couple is taken out from the quartz tube, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com