Preparation method of oat beta-glucan aqueous solution applied to cosmetics

A glucan and aqueous solution technology, applied in the field of preparation of oat beta-glucan aqueous solution, can solve problems such as increased production cost, easy precipitation, poor stability, etc., to reduce the content of impurities such as starch, improve extraction rate, and improve The effect of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

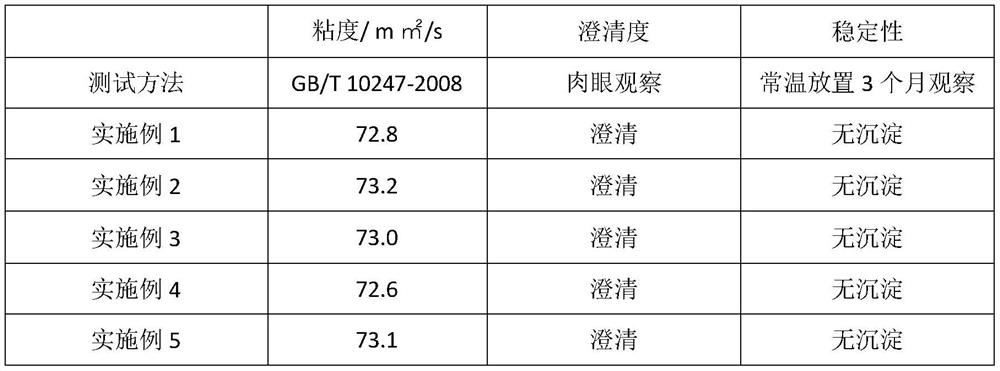

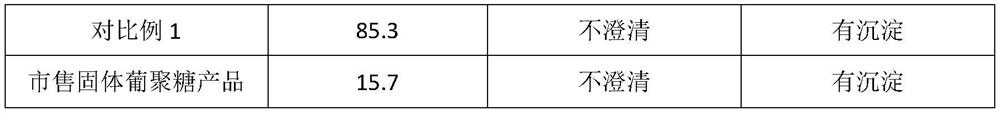

Examples

Embodiment 1

[0027] A method of preparing an oatmeal β-dextran applied to cosmetics, including the following steps:

[0028] S1, stirring the cold water of oat bran and 5 ° C to stir the mixture ratio of 1 g: 4 mL, filter collect the filter residue, the filter residue repeats is cleaned with cold water 3, and the starch impurities are removed.

[0029]S2, add 12 times mass of water to filter residue, stir it to 40 ° C, add 0.1% protease of oat bran mass for enzymatic, enzymatic solution for 45 minutes;

[0030] After the end of the enzymatic solution, the enzyme solution continued to 90 ° C, and the heat extraction was carried out, and in particular, it was carried out to stir the enzymatic hydrolyzate to dissolve the glucan from bran, and extracted for 2 hours;

[0031] S4, extract the end post-adjusted equal electricity point, specifically, the reaction liquid is adjusted with phosphoric acid to adjust the pH of 4.5, and the protein is precipitated, centrifuged, and the liquid is filtered by...

Embodiment 2

[0033] A method of preparing an oatmeal β-dextran applied to cosmetics, including the following steps:

[0034] S1, stirring the cold water of oat bran and 7 ° C to stir the mixture ratio of 1 g: 5 mL, filter collect the filter residue, the filter residue is repeated with cold water 2, and the starch impurities are removed.

[0035] S2, add 13 times mass of water to filter residue, stir it to 45 ° C, add 0.2% protease of oat bran mass of 0.2% by enzymatic solution, enzymatic solution 40 minutes;

[0036] After the end of the enzymatic solution, the enzyme solution continued to 91 ° C, and the heat extraction was carried out, and it is specifically comprised that the enzymatic hydrolyzate is stirred and heated to dissolve the glucan from bran, and extract 1.8 hours;

[0037] S4, extract the end post-adjusted equal electricity point, specifically, the reaction liquid is adjusted with phosphoric acid to adjust the pH of 4.5, and the protein is precipitated, centrifuged, and the liqui...

Embodiment 3

[0039] A method of preparing an oatmeal β-dextran applied to cosmetics, including the following steps:

[0040] S1, stirring the cold water of oat bran and 10 ° C to stir the mixture ratio 1 g: 6 mL, filter collect the filter residue, the filter residue repeats is cleaned with cold water 4 times, and the starch impurities are removed.

[0041] S2, add 14 times mass of water to filter residue, stir it to 50 ° C, add 0.3% protease of oat bran mass of 0.3%, enzymatic solution for 37 minutes;

[0042] After the end of the enzymatic solution, the enzyme solution continued to 92 ° C, and the heat extraction was carried out, and it is specifically comprised that the enzymatic hydrolyzate is stirred and heated to dissolve the glucan from bran, extracting 1.5 hours;

[0043] S4, extract the end post-adjusted equal electricity point, specifically, the reaction liquid is adjusted with phosphoric acid to adjust the pH of 4.5, and the protein is precipitated, centrifuged, and the liquid is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com