Preparation method and application of slag-fly ash geopolymer

A geopolymer, fly ash technology, applied in solid waste management, sustainable waste treatment, cement production, etc., can solve problems such as low production cost and heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

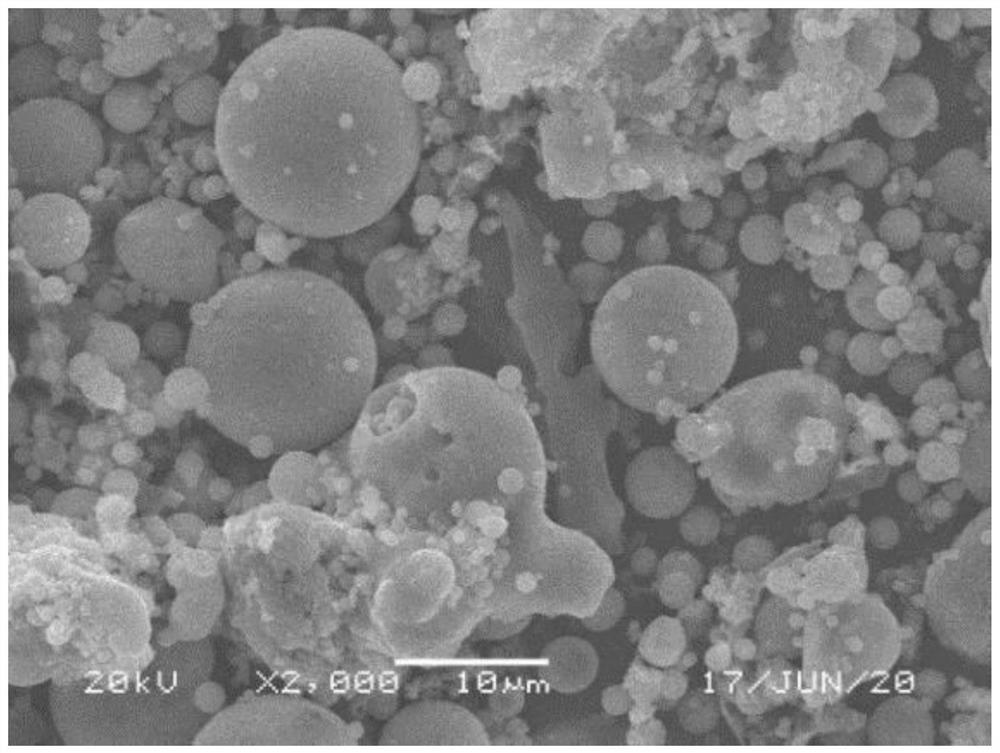

Image

Examples

Embodiment 1

[0046] A preparation method of slag-fly ash geopolymer, comprising the following steps:

[0047] (a) Water glass, sodium hydroxide solid, and water are mixed into a clarified alkali activator with a modulus of 1.4 by magnetic stirring, and sealed for 24 hours;

[0048] (b) Grinding the slag and passing through a 0.25mm sieve, stirring the finely ground slag and low-calcium fly ash evenly, the slag dosage is 10% of the total mass of the slag and low-calcium fly ash; The fly ash mixture is stirred and mixed with an alkali activator to make a slurry with a water-solid ratio of 0.29, wherein the amount of the alkali activator is 30% of the total mass of the slag and low-calcium fly ash;

[0049] (c) Evenly coat vaseline in the triple mold, inject the slurry in 3 times, and after filling, place the triple mold with the slurry on a vibrating table to vibrate for 3 minutes to eliminate air bubbles and vibrate to obtain the first sample;

[0050] (d) Seal the initial sample with a pl...

Embodiment 2~10

[0052] The slag-fly ash geopolymer was prepared according to the method of Example 1. The alkali activator modulus, slag content, slurry water-solid ratio, and alkali activator content of each example are shown in Table 1.

[0053] Table 1

[0054]

[0055] The compressive strength test was carried out on the slag-fly ash geopolymer prepared in Examples 1-10, and the results are shown in Table 2. As can be seen from Table 2, the geopolymer with higher compressive strength can be prepared by the preparation method of the present invention, and along with the growth of the curing age, the compressive strength of the geopolymer is a trend of increasing, embodiment 10 The compressive strength of the prepared geopolymer is the best.

[0056] Table 2

[0057]

[0058]

[0059] The slag-fly ash geopolymer can be used as a curing agent to stabilize heavy metal contaminated soil.

Embodiment 11

[0061] Geopolymers are applied to the solidification of heavy metal-contaminated soils, and the specific methods are:

[0062] (a) Water glass, sodium hydroxide solid, and water are mixed into a clarified alkali activator with a modulus of 1.4 by magnetic stirring, and sealed for 24 hours;

[0063] (b) Pre-stir the heavy metal contaminated soil; grind the slag and pass through a 0.25mm sieve, add the finely ground slag and low-calcium fly ash into the heavy metal contaminated soil and stir evenly; then add an alkali activator and stir to prepare into a mixture;

[0064] (c) Apply vaseline evenly in the triple mold, inject the mixture in 3 times, after filling, place the triple mold with the mixture on a vibrating table to vibrate for 3 minutes to eliminate air bubbles and vibrate to obtain the first product;

[0065] (d) Seal the primary product with a plastic wrap to isolate the air, place it at room temperature (20±2°C) for 24 hours, and then release the mold to obtain a he...

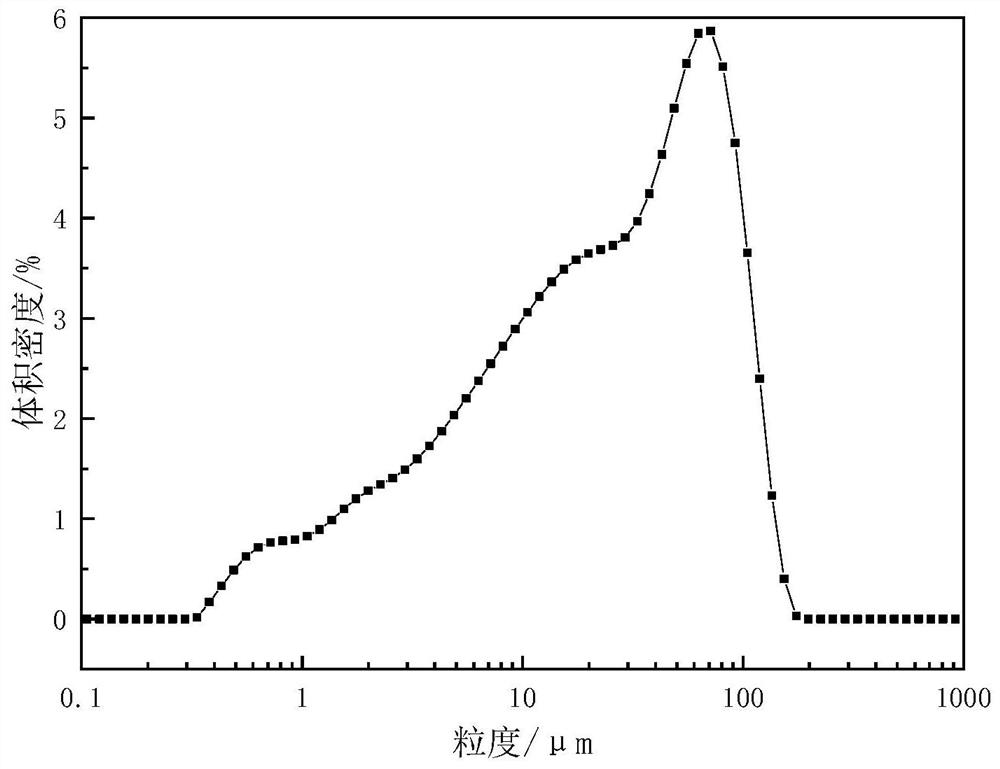

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com