High-performance hard-surface surfacing flux-cored wire

A high-performance, hard-faced technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems of complex wear-resistant ceramic inlay manufacturing process, high-cost use effect, and high cost, and reduce welding materials Cost and maintenance costs, significant economic and social benefits, effects of improved wear resistance and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

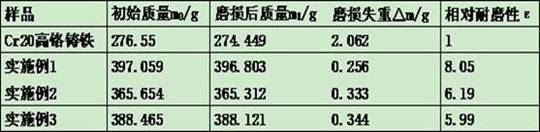

Examples

Embodiment 1

[0013] The high-performance hard surface-welded core welding wire is composed of the outer skin and the dielectric core, the composition and weight included in the dielectric core: chromium: 51%; graphite 12%; silicon: 2.50%; manganese : 1.45%; molybdenum: 0.21%; nickel: 0.53%; niobium: 13.2%; titanium 0.47%; aluminum: 0.21%; vanadium: 1.06%; titanium: 0.43%; copper: 0.21%, iron: margin.

[0014] Niobium (NB): can refine the grain and reduce the overheating sensitivity of the steel and the backfire, improve the strength, improve the welding performance refine grain, the rectification of the reinforcement, the alloy steel and the carbon element reaction Generate tantalum rigid phase, micro hardness> 235 GPa (> 2400 kg / mm2), is still hard than Ji Yugu. Therefore, a certain proportion of can improve the overall hardness and wear resistance of the diesel wire wire can be greatly improved.

[0015] Its preparation step is: 1) Pharmaceutical core components are mixed with the formulat...

Embodiment 2

[0017] The high-performance hard surface-welded core welding wire is composed of the outer skin and the core, and the components and weight included in the dielectric core are: chromium: 44.2%; graphite: 11.02%; silicon: 2.27%; Manganese: 1.45%; molybdenum: 0.21%; nickel: 0.54%;: 0.53%; aluminum: 0.21%; vanadium: 1.02%; titanium: 0.43%; copper: 0.21%; iron: margin.

[0018] The preparation step is: 1) The components of the die core are mixed according to the formulation and thoroughly stir it. After mixing, it is placed in a dryer to dry, 150 ° C insulation for 1 h, resulting in a pharmaceutical core powder; 2) Place the outer skin in medicine On the belt machine of the core welding wire, the outer skin is selected from the SPCC steel strip, and the outer skin steel strip is rolled into a U-shaped groove, and then the core powder is added to the U-groove, the filling rate of the drug core powder is 48%. Then, then the U-tank is crushed by the molding machine, drawn to a diameter o...

Embodiment 3

[0020] The high-performance hard surface of the present invention consists of the outer skin and the core, and the components contained in the dielectric core are: chromium: 47.9%; graphite: 11.45%; silicon: 2.34%; Manganese: 1.45%; molybdenum: 0.21%; nickel: 0.45%; titanium: 0.45%; aluminum: 0.21%; vanadium: 1.0%; titanium: 0.43%; copper: 0.21%; iron: margin.

[0021] The preparation step is: 1) The components of the die core are mixed according to the formulation and thoroughly stir it. After mixing, it is placed in a dryer to dry, 140 ° C is held in 1 h, resulting in a pharmaceutical core powder; 2) Place the outer skin in the medicine On the belt machine of the core welding wire, the outer skin is selected from the SPCC steel strip, and the outer skin steel strip is rolled into a U-shaped groove, and then the core powder is added to the U-groove, the filling rate of the drug core powder is 48%. Then, then the U-tank is crushed by the molding machine, drawn to a diameter of 2.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com