Revetment structure composed of plastic steel plate piles and concrete

A technology of concrete and plastic steel plate, applied in the field of bank protection structure, can solve the problems of large surrounding working face, large impact on the surrounding environment, loss of forest resources, etc., to achieve the effect of protecting dams, resisting wave impact, and reducing silt at the bottom of the river.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

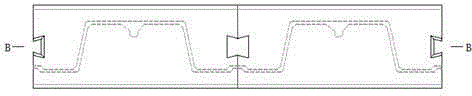

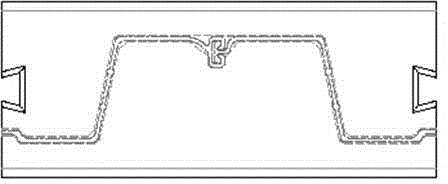

[0030] In the combination diagram, the protruding side of the plastic sheet pile is the water-facing surface, and the back side is the complex soil. The plastic steel sheet pile is pressed into the soil first, and the upper part is repressed with the prefabricated concrete slab, and there is a groove facing the side of the sheet pile. The groove at the head is 12 mm wide and 3 mm deep; there are large inner and outer small grooves in the middle of the edges of the two ends of the concrete topping. The two toppings are connected to each other by connecting blocks that match the grooves. Symmetrical dovetail joints at both ends, the dimensions are: A is 75 mm, a is 50 mm, B is 56 mm, b is 36 mm, the height is the same as the thickness of the roof plate, and the length of the precast concrete roof is 760 mm.

Embodiment 2

[0032] In the combination diagram, the protruding side of the plastic sheet pile is the water-facing surface, and the back side is the complex soil. Press the plastic steel sheet pile into the soil first, then repress the upper part

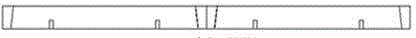

[0033] "∏" shaped prefabricated concrete roof, the specific dimensions are: the thickness of the upper horizontal plate of the roof is 60 mm, the thickness of the vertical plate is 40 mm, the inner distance between the two vertical plates is 184 mm, the length of the vertical plate is 200 mm, and the upper edge of the lower end of the vertical plate is 50 mm Avoid the position of the connector, reserve a hole with a diameter of 12 mm, pass through a stainless steel screw with a diameter of 10 mm after installation, fix it with screws and nuts, and put a galvanized pipe in the middle of the two plates. The precast concrete topping length is 1520 mm. A 10 mm diameter hook is symmetrically installed at both ends of the inner side of the concrete to...

Embodiment 3

[0035] The protruding side of the plastic steel sheet pile in the combined picture is the water-facing surface, and the back side is the compound soil. First, press the plastic steel sheet pile into the soil, then repress the concrete on the upper part, and form a groove in the middle of the two vertical slabs along the connection direction of the sheet pile, which is consistent with the M shape of the upper end of the sheet pile. The plate thickness is 40mm, the groove width is 10mm, the groove width at the joint is 12mm, and the riser length is 60mm; the precast concrete topping length is 1520mm. A 10 mm diameter hook is symmetrically installed at both ends of the inner side of the concrete top slab to lift the precast concrete top slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com