High-low voltage switch cabinet metal plate manufacturing and assembling machine and assembling method

A high and low voltage switchgear and cabinet sheet metal technology, applied in the direction of switchgear, manufacturing tools, auxiliary devices, etc., can solve problems such as unstable assembly methods, assembly misalignment, and reduced assembly efficiency of high and low voltage switchgear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

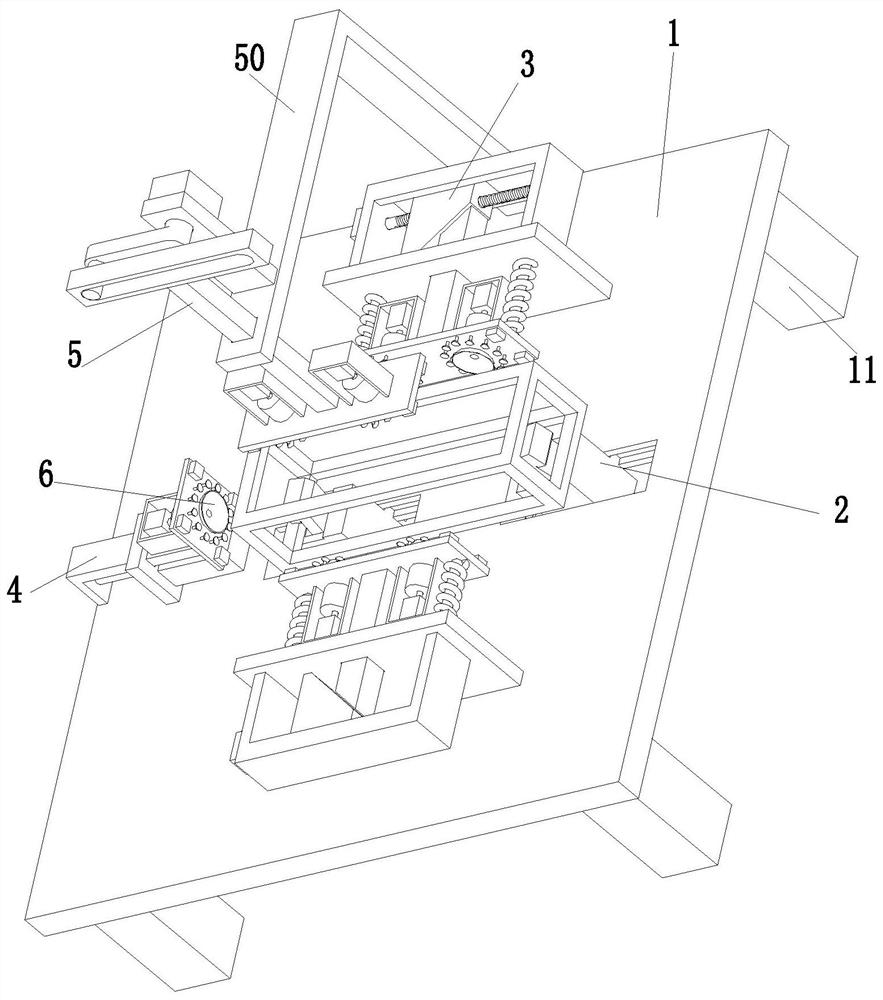

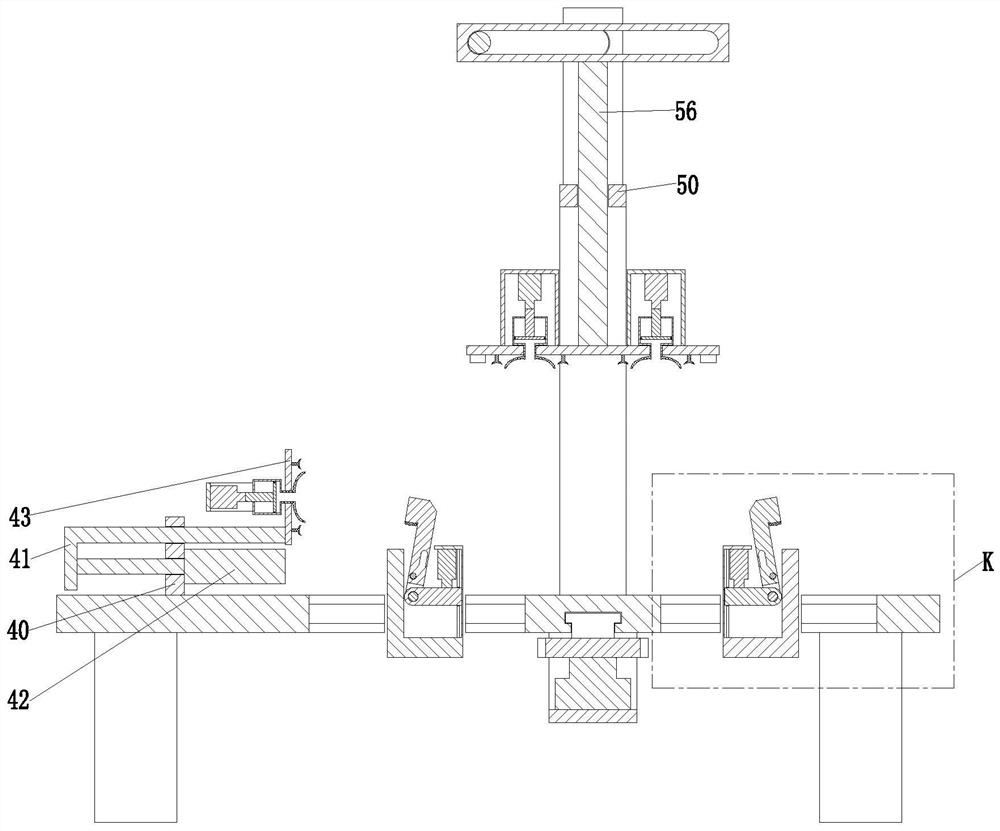

[0039] Such as Figure 1 to Figure 10 As shown, a high and low voltage switchgear sheet metal manufacturing and assembly machine includes a base plate 1, a positioning device 2, a propulsion device 3, a pressing device 4 and a pressing device 5. The positioning device 2 is installed on the base plate 1, and the base plate 1 is equipped with a propelling device 3 symmetrically front and rear, a pressing device 4 is installed at the left end of the base plate 1, and a pressing device 5 is installed at the rear end of the base plate 1.

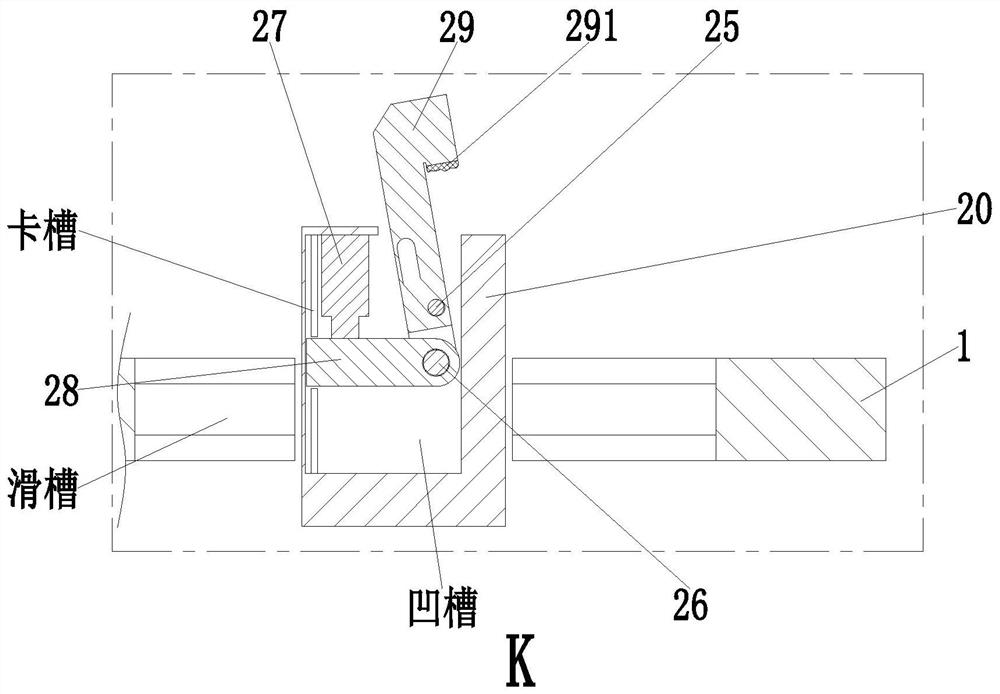

[0040] The positioning device 2 includes a sliding plate 20, a U-shaped plate 21, a No. 1 motor 22, a driving gear 23, a driven rack 24, a positioning round rod 25, a pushing round rod 26, a telescopic cylinder 27, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com