Assembling equipment for furniture production and assembling process

A technology for assembling equipment and furniture, applied in the field of furniture, can solve the problems of reducing the profit space of profitable companies, inconvenient to fix furniture parts, and increase the workload of staff, so as to improve the practical scope, facilitate human-computer interaction, and avoid monolithic problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

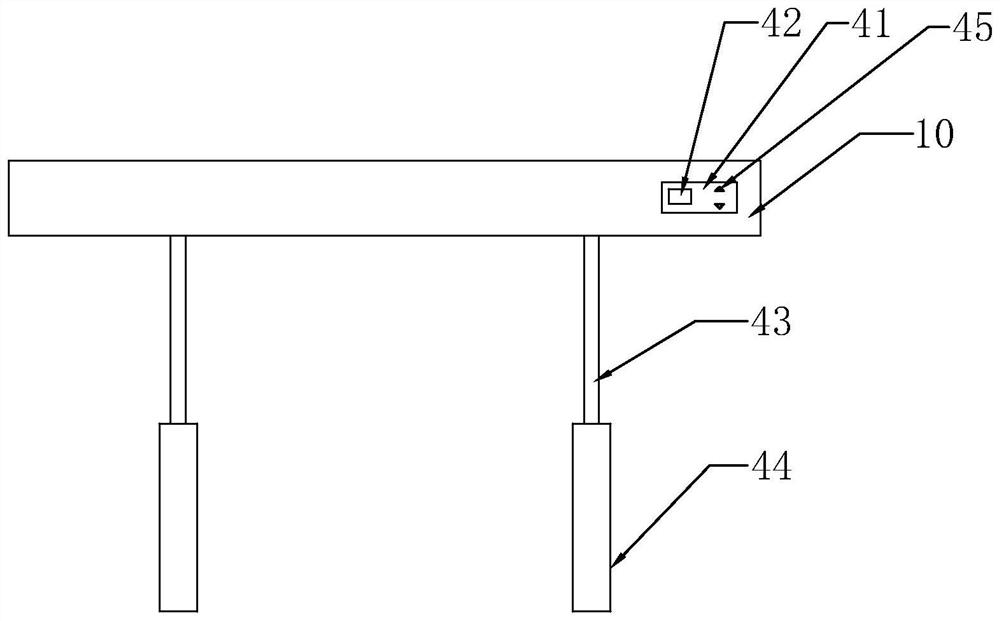

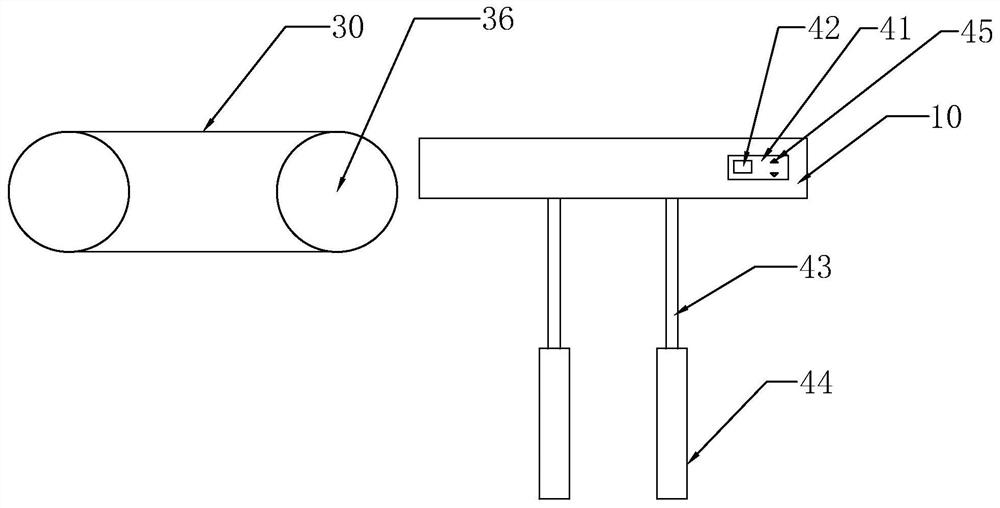

[0039] Such as figure 1 As shown, the present invention discloses an assembly equipment for furniture production, which is characterized in that: it includes a placement platform 10 for placing furniture parts that need to be assembled;

[0040] The manipulator 20 is used to grab furniture parts that need to be assembled;

[0041] The conveyor belt 30 is used for transporting the furniture parts that need to be assembled.

[0042] In a specific embodiment of the present invention, the placement platform 10 includes a height adjustment device 40, and the height adjustment device 40 includes a PLC control panel 41, a display 42, a height telescopic rod 43, a height hydraulic cylinder 44, and an adjustable button 45. The PLC control panel 41 is arranged on the side of the placement platform 10, the PLC control panel 41 is provided with the display 42, the display 42 is embedded with the adjustment button 45, and the PLC control panel 41 The height hydraulic cylinder 44 is contr...

Embodiment 2

[0044] Embodiment 2 is different from Embodiment 1 in that

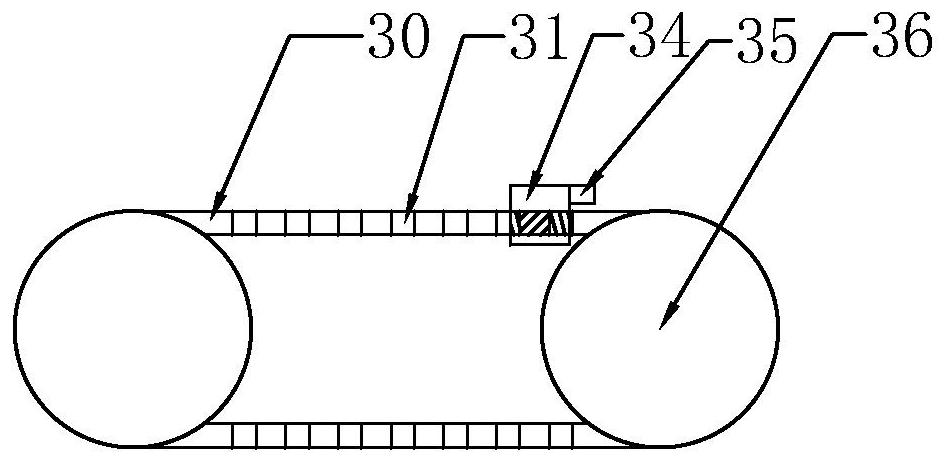

[0045] Such as Figure 2-Figure 4 As shown, in a specific embodiment of the present invention, the conveyor belt 30 is arranged on one side of the placement platform 10, and the conveyor belt 30 is spirally wound into a racetrack shape, and there is an interval between every two layers of conveyor belts 30, so The conveyor belt 30 adopts the core-spun cord as the warp yarn, and the high-density polyethylene fiber and the polyester cord are twisted and twisted as the weft yarn to be made by plain weaving process; several cavities 31 are arranged between every two layers of conveyor belts 30, each A compression spring 32 is provided in the cavity 31 , and a wear-resistant rubber 33 is provided in the middle of the conveyor belt 30 .

[0046] In a specific embodiment of the present invention, the side of the conveyor belt 30 close to the placement platform 10 is provided with an infrared detector 34, the height of the ...

Embodiment 3

[0048] Embodiment 3 is different from Embodiment 2 in that

[0049] Such as Figure 5-Figure 6 As shown, in the specific embodiment of the present invention, the manipulator 20 is arranged on one side of the placement platform 10 and is close to the conveyor belt 30 .

[0050] In a specific embodiment of the present invention, the manipulator 20 includes a base 21, a first telescopic rod 22, a first hydraulic cylinder 23, a mechanical arm 24, a second telescopic rod 25, a second hydraulic cylinder 26, a mechanical clamp 27 and a control Computer 28, the bottom of the base 21 is provided with a first hydraulic cylinder 23, the side of the first hydraulic cylinder 23 away from the base 21 is connected to the first telescopic rod 22, and the first telescopic rod 22 is away from One side of the first hydraulic rod is provided with the second telescopic rod 25, and the side of the second telescopic rod 25 close to the first telescopic rod 22 is provided with the second hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com