Assembling equipment for clutch assembly and assembling method for clutch assembly

A technology for clutch components and assembly equipment, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as component deformation, reduced product production efficiency, and impact on the service life of business machines, reducing extrusion deformation and reducing production. efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

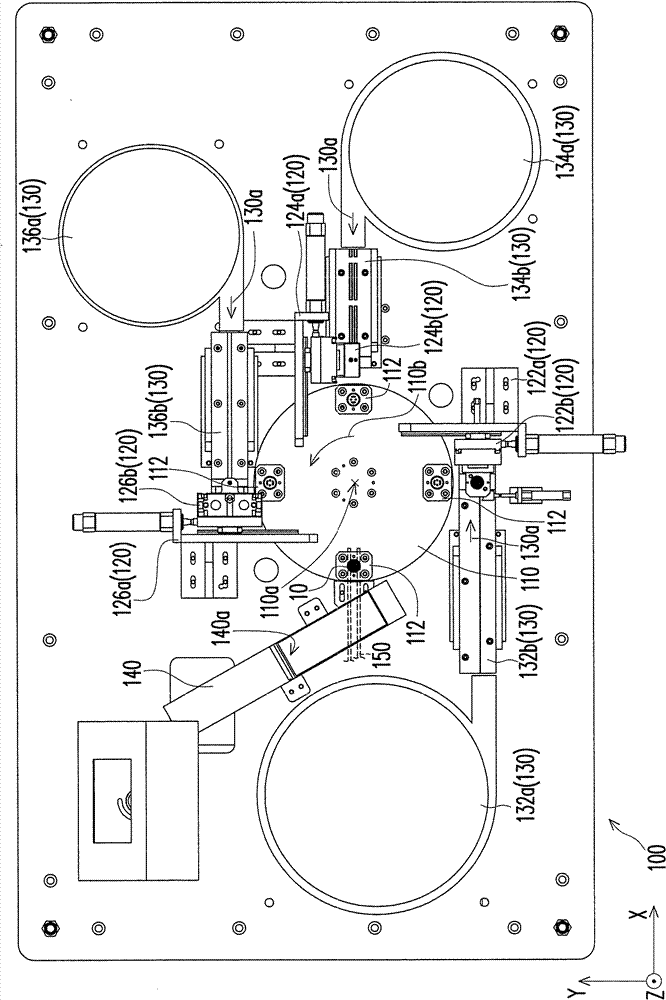

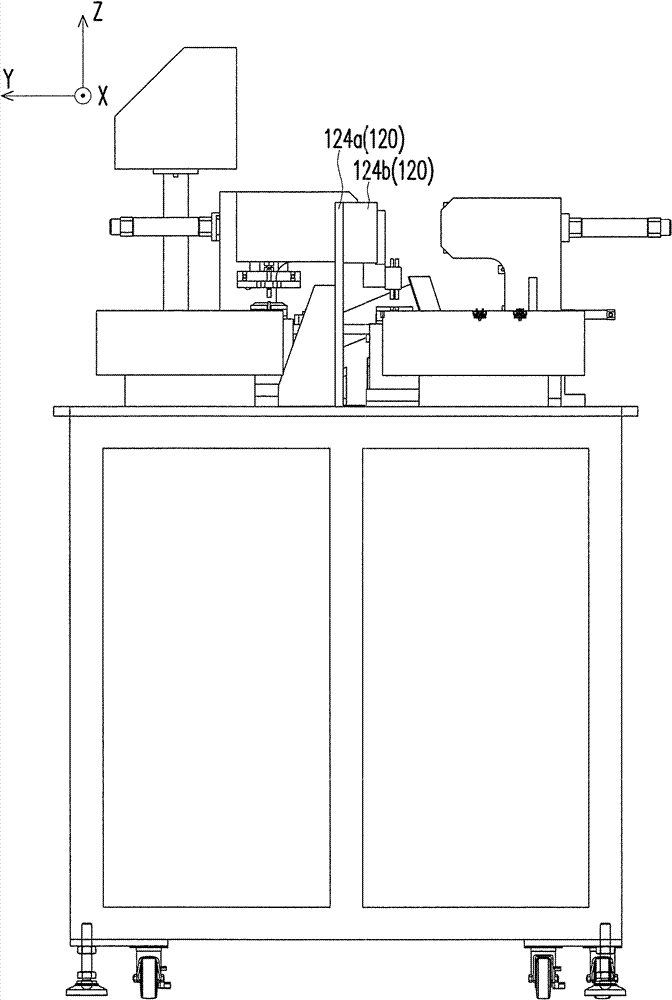

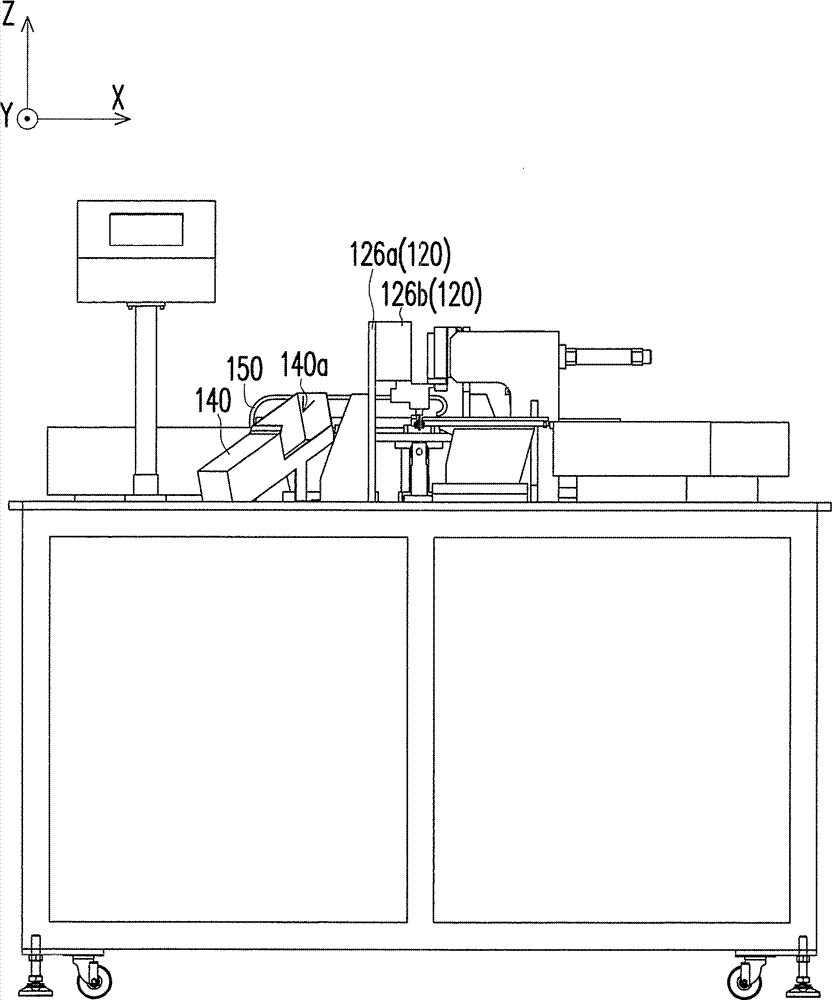

[0037] Figure 1A , Figure 1B and Figure 1C They are respectively a top view, a side view and a front view of the assembly equipment of the clutch assembly according to an embodiment of the present invention. figure 2 It is an exploded view of the clutch assembly in Fig. 1 . Please refer to Figure 1A , Figure 1B , Figure 1C and figure 2 , in this embodiment, the clutch assembly assembly equipment 100 is suitable for assembling a first part 12, a second part 14 and two transmission members 16 of a clutch assembly 10, wherein the clutch assembly 10 is suitable for installing In a business machine (not shown), it is used as a transmission member for power switching of the business machine.

[0038] The clutch assembly assembly equipment 100 includes a rotating base 110 , a plurality of assembly units 120 and a plurality of transfer units 130 . The rotating base 110 has a rotating center 110a and a plurality of receiving parts 112 . The receiving part 112 rotates alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com