Calcium sulfate whisker powder screening device

A calcium sulfate whisker and screening device technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of manual feeding that cannot control the speed, easy to block the feeding port, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

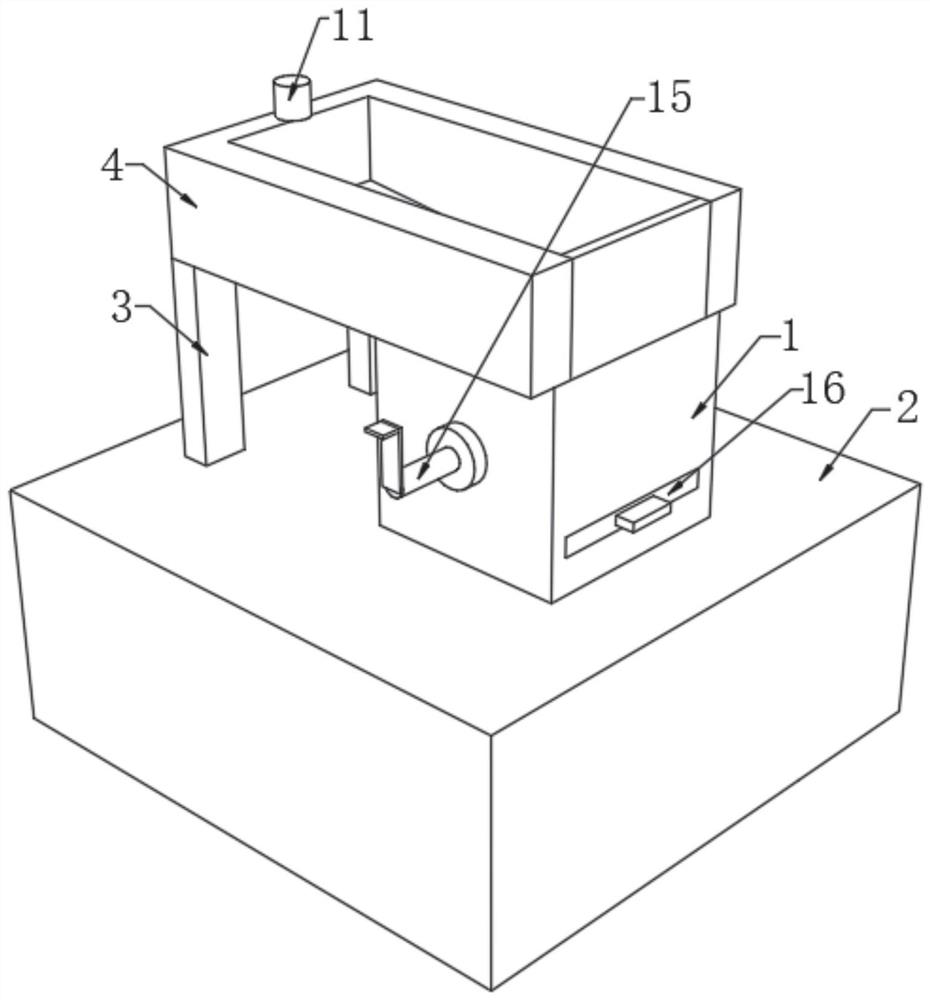

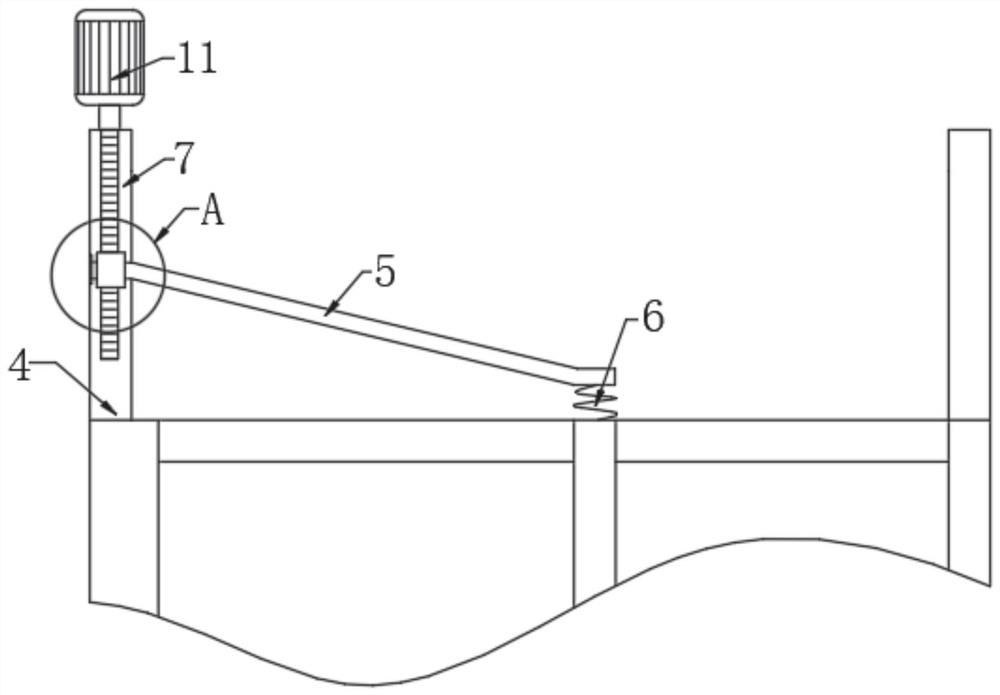

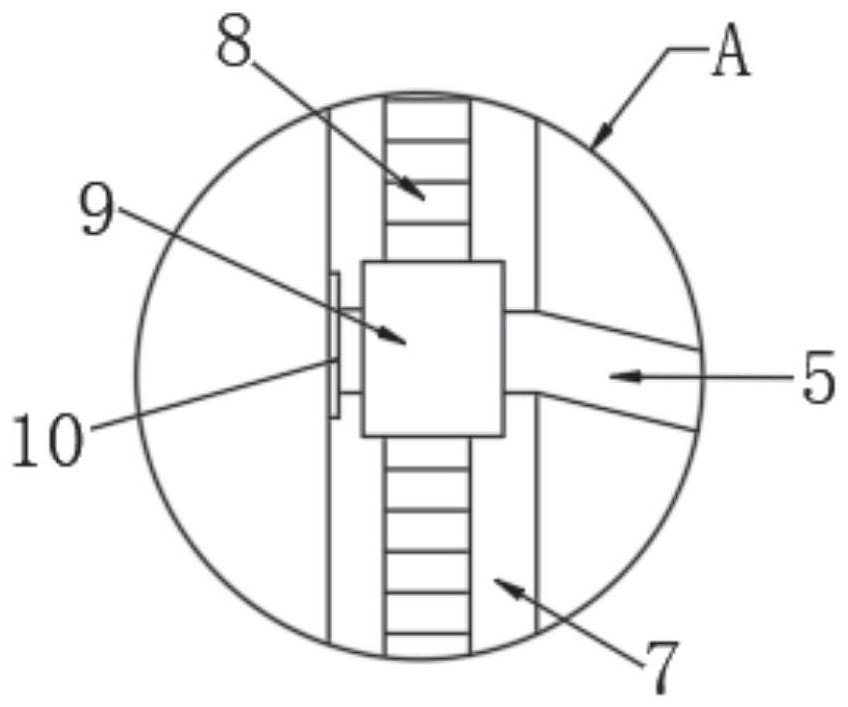

[0024] Such as Figure 1-Figure 4 As shown, a calcium sulfate whisker powder screening device includes a feed box 1, the bottom of the feed box 1 is connected with a screening box 2, and the back of the top of the screening box 2 is fixedly connected with two support columns 3, The height of the two support columns 3 is consistent with the height of the feed box 1, the top of the support column 3 is fixedly equipped with a coaming 4, the bottom of the coaming 4 is fixedly connected with the feed box 1, and the middle part of the front of the top of the feed box 1 A connecting spring 6 is fixedly arranged, and the inner wall of the coaming plate 4 is movably connected with a feeding plate 5, and one end of the feeding plate 5 is fixedly connected with the connecting spring 6, and the setting of the connecting spring 6 plays the role of fixing one end of the feeding plate 5, and The top of the back of the plate 4 is provided with an operation groove 7, the inside of the operatio...

Embodiment 2

[0027] On the basis of Example 1, as figure 1 and Figure 4 As shown, both sides of the middle part of the inner wall of the feed box 1 are rotatably connected with a rotating shaft 14 through the provided bearings, and the adjacent ends of the two rotating shafts 14 are fixedly connected with a stirring rod 12, and the outer wall of the stirring rod 12 is fixedly connected with a plurality of stirring rods. Blade 13, the length of a plurality of stirring blades 13 is less than half of the length of the feed box 1, the rotating rocker 15 drives the rotating shaft 14 to rotate, and the rotating shaft 14 drives the stirring rod 12 to rotate to make the stirring blade 13 rotate, so as to achieve the first step of the powder in the feeding. Stir to make it evenly and orderly drop onto the filter screen 16. One end of the stirring rod 12 runs through the feed box 1 and is fixedly connected with a rocking bar 15. The bottom of the feed box 1 inner wall is movably connected with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com