Automatic cementing material density measurement and feeding system

A technology of density determination and feeding system, which is applied to automatic feeding/discharging weighing equipment, analyzing materials, measuring devices, etc. problems, to achieve the effect of improving detection efficiency, ensuring continuity, and ensuring measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

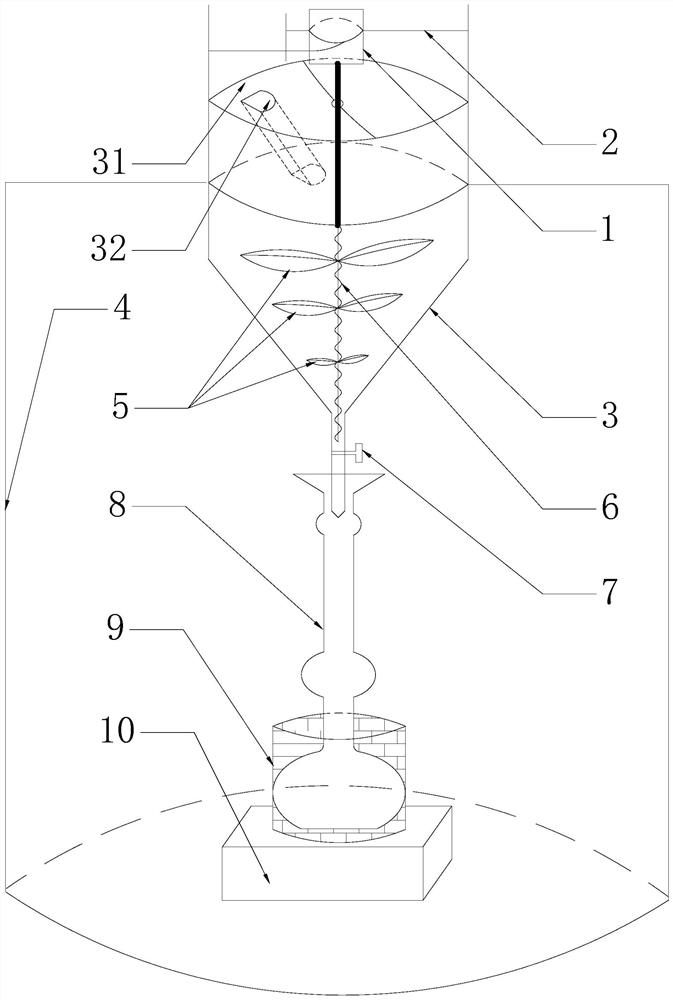

[0025] Such as figure 1 The shown automatic gelling material density measurement and feeding system includes a motor 1, a storage and feeding bin 3, a Lee bottle 8 and a weighing device 10. The motor 1 is equipped with a motor fixing device 2 that can be adjusted up and down, and the bottom of the motor 1 is Connected with the screw feeder 6 and the feeding blade 5 fixedly connected to the screw feeder 6, the storage material feeding bin 3 is provided with a cover and a feeding pipe 32 arranged on the cover, the feeding blade 5 and the screw bottom The feeder 6 is arranged in the middle of the material storage and feeding bin 3, and the Lee's bottle 8 is fixedly arranged by the Lee's bottle fixing fixture 9 and the weighing device 10 . The motor fixing device 2 is slidingly connected up and down with the storage and feeding bin 3, and the storage and feeding bin 3 is fixed on the feeding device support 4. The material storage and feeding bin 3 adopts a funnel-shaped structure...

Embodiment 2

[0028] An automatic gelling material density measurement and feeding system, including a motor 1, a material storage and feeding bin 3, a Lee bottle 8 and a weighing device 10, the motor 1 is equipped with a motor fixing device 2 that can be adjusted up and down, and a screw is connected below the motor 1 The feeding device 6 and the feeding blade 5 fixedly connected to the screw feeding device 6, the storage feeding bin 3 is provided with a cover and a feeding pipe 32 arranged on the cover, the feeding blade 5 and the screw feeding device 6 It is arranged in the middle of the material storage and feeding bin 3, and the Lee's bottle 8 is fixedly set by the Lee's bottle fixing fixture 9 and the weighing device 10. The motor fixing device 2 is slidingly connected up and down with the storage and feeding bin 3, and the storage and feeding bin 3 is fixed on the feeding device support 4. The material storage and feeding bin 3 adopts a funnel-shaped structure, and the middle section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com