Positive-pressure conveying method for light powder and particle materials

A positive pressure conveying and powder technology, which is used in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problem of light materials being difficult to unload, and achieve the effect of simple structure and saving of exhaust valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

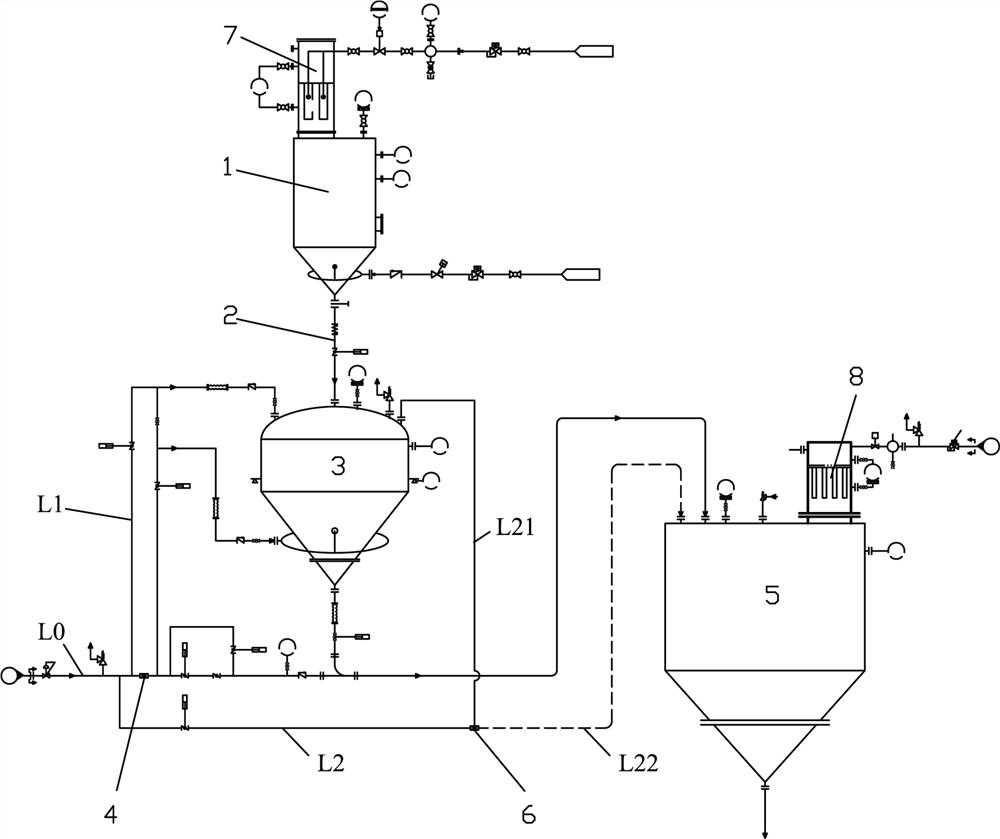

[0021] see figure 2 , the positive pressure conveying method of light powder and pellets according to the present invention, the material stored in the source bin 1 is conveyed to the sending tank 3 through the feed pipeline 2, and the sending tank 3 passes through the conveying pipeline L0, the control valve and the pulling method The pipe 4 transports the material to the destination silo 5 by the conveying gas; during this period, a pressurized gas pipeline L1 and a gas pipeline L2 and corresponding control valves are drawn from the conveying pipeline in front of the Lafa pipe 4. The other end of the compressed air line L1 is connected to the sending tank 3, and the sending tank 3 is pressurized; a suction nozzle 6 is set in the gas delivery line L2, and a suction line L21 is connected to the air suction nozzle 6 from the suction nozzle 6. The sending tank 3 is described, and the sending tank 3 is sprayed and sucked to realize accelerated feeding; under the combined action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com