Multistage plunger hydraulic sludge pump

A hydraulic and sludge pump technology, applied in the direction of variable displacement pump components, pump components, liquid fuel engines, etc., can solve the problems of high energy consumption and high power, and achieve low energy consumption, large flow, and shorten the feeding. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

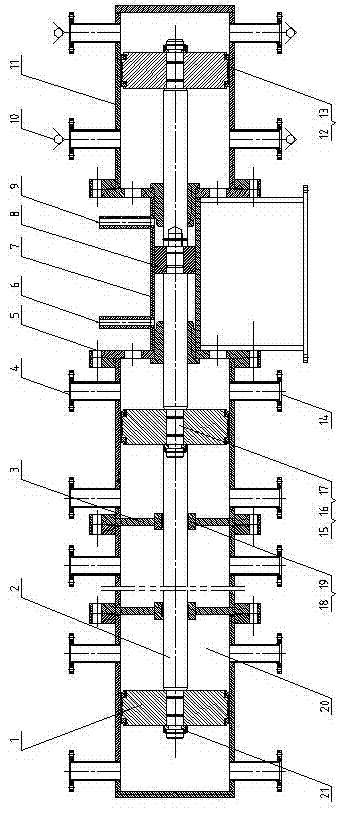

[0017] Such as figure 1 As shown, a multi-stage plunger hydraulic sludge pump consists of plunger 1, plunger rod 2, partition 3, sludge discharge port 4, connecting assembly 5, hydraulic oil inlet 6, power cylinder 7, column Plug 8, hydraulic oil outlet 9, one-way valve 10, single-stage working cylinder 11, sealing groove 12, sealing assembly 13, sludge inlet 14, stepped shaft 15, sealing groove 16, shaft sealing ring 17, sealing Groove 18, hole sealing ring 19, sludge chamber 20, fastener 21 constitute.

[0018] A multi-stage plunger hydraulic sludge pump, including a working cylinder and a power cylinder composed of a cylinder body and a plunger, is provided with at least one working cylinder 11 and a power cylinder 7, and the working cylinder 11 and a power cylinder 7 are connected by The assembly 5 is axially connected as a whole, and the plunger rods 2 of the plunge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com