Automatic feeding device for drilling fluid circulating tank

A technology of automatic feeding device and drilling fluid circulation, which is used in earth-moving drilling, flushing wellbore, wellbore/well components, etc. It can solve the problems of large influence of drilling fluid performance, splash of treatment agent, uneven feeding speed, etc. , to achieve the effect of eliminating hidden safety hazards, reducing labor, and saving personnel energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 10

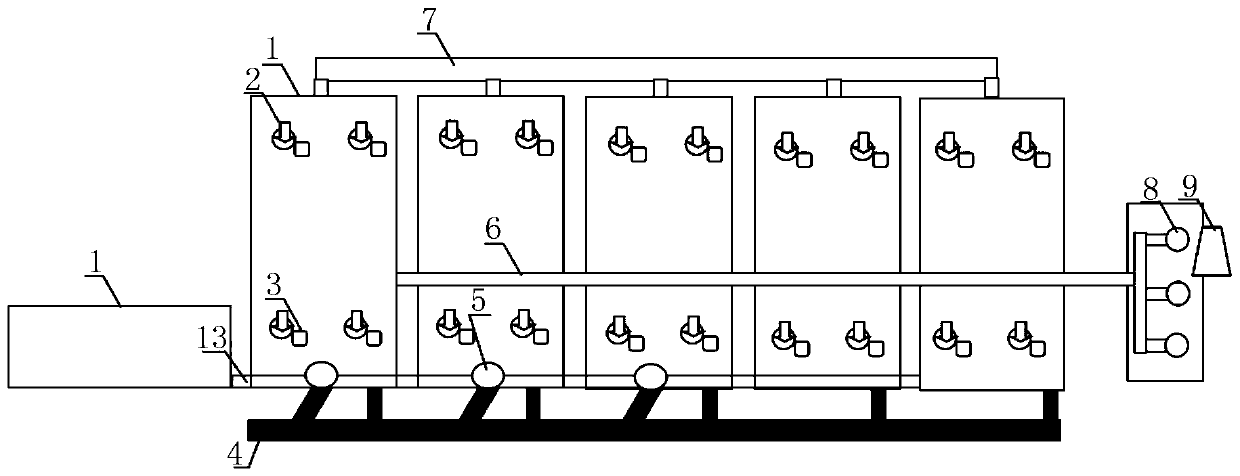

[0050] Embodiment 1-Embodiment 10 is an embodiment description of a drilling fluid circulation tank system;

Embodiment 11- Embodiment 20

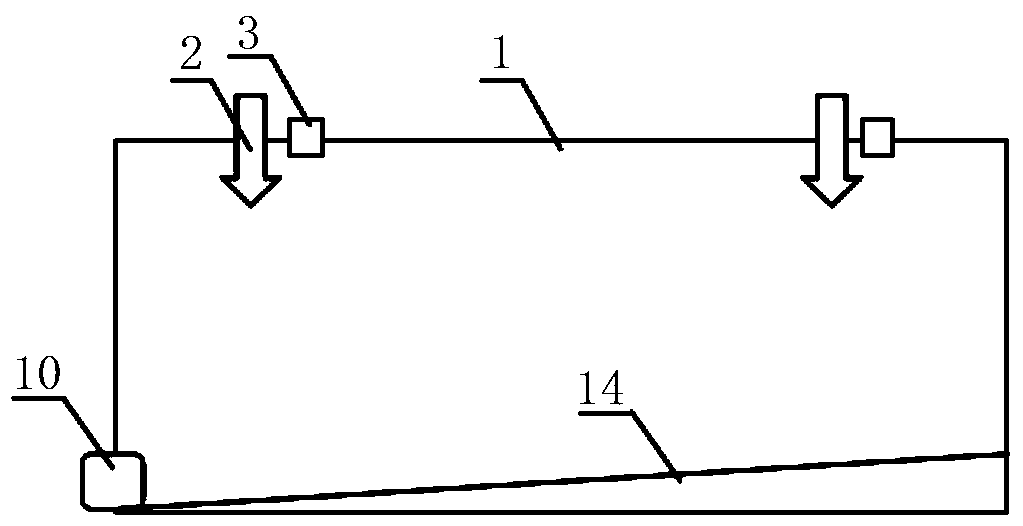

[0051] Embodiment 11-embodiment 20 is a kind of embodiment description of circulating irrigation;

Embodiment 21- Embodiment 27

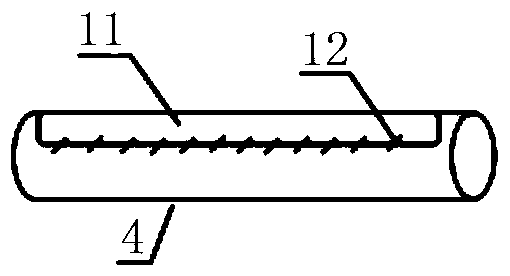

[0052] Embodiment 21-Embodiment 27 is a description of the embodiment of a drill cuttings airtight transmission system;

[0053] Embodiment 28-Embodiment 35 is an embodiment description of an automatic feeding device for a drilling fluid circulation tank;

[0054] One of the circulation irrigation is a detailed description of the circulation tank 1 in a drilling fluid circulation tank system; a drill cuttings closed transmission system is a connection between the circulation irrigation 1 and the buried tank 18 in a drilling fluid circulation tank system The detailed description of the pipeline for drilling cuttings; an automatic feeding device for drilling fluid circulation tank is a detailed description of a batching device for supplying drilling fluid to the slurry mixing suction line 6 in the drilling fluid circulation tank system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com