Preparation method of powder net composite porous metal film

A technology of porous metal and thin film, which is applied in the field of preparation of powder mesh composite porous metal thin film, which can solve the problems of easy corrosion and temperature difference, and achieve the effects of low production cost, low defect rate and high filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

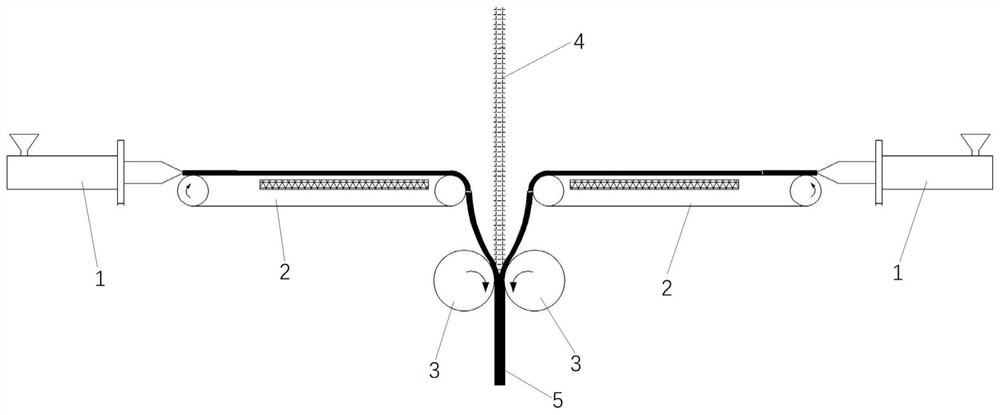

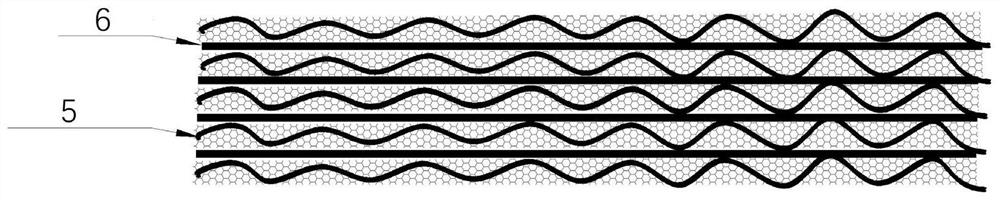

[0031] The invention provides a preparation method of a powder mesh composite porous metal film, such as figure 1 As shown, add plasticizer, thickener, organic solution or deionized water, add metal powder, stir and disperse, and finally prepare a high-viscosity slurry system. Pour the prepared high-viscosity slurry system into the extruder 1 with a slit-shaped die installed on the machine head, extrude the film from the machine head and transfer it to the two-roll rolling machine 3 through the conveyor belt 2, and pass the composite film on both sides, and the two A sheet of metal film green body is combined with a single-layer wire mesh 4, and the film green body and the wire mesh are combined by composite rolling to form an integrated symmetrical film structure, that is, a powder mesh composite porous metal film green body 5, which is then degreased and sintered. A powder mesh composite porous metal film with uniform pore size and controllable thickness was prepared. Speci...

Embodiment 1

[0039] 1. Prepare PVB ethanol solution at a mass ratio of 1:15. After aging for 24 hours, stir and mix glycerol and PVB ethanol solution at a mass ratio of 1:20 to obtain a mixed liquid.

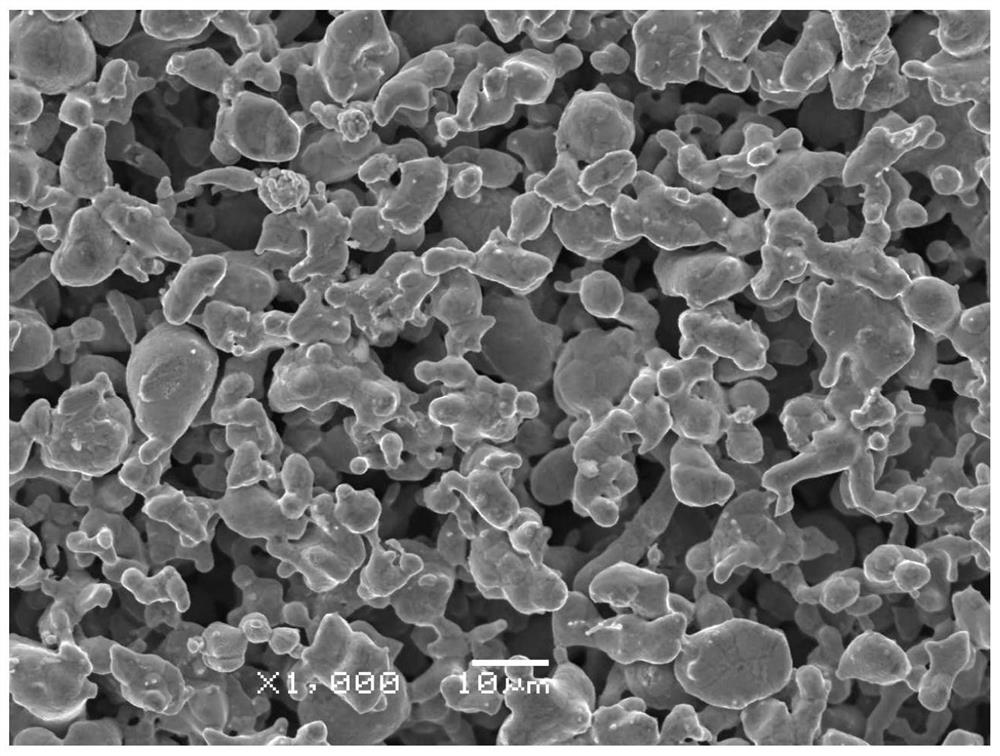

[0040] 2. The Fe with an average particle size of 15 μm 3 Mix the Al alloy powder and the mixed liquid at a mass ratio of 5:1, slowly add the metal powder, and stir to obtain a viscous slurry system;

[0041] 3. Pour the viscous slurry system into two extruders, and extrude the film body from the slit-shaped die mouth with a size of 300mm×200μm under the push of the screw, and slowly transfer the conveyor belt to the two-roll rolling machine; from the middle top Place a 350mm wide 60-mesh FeCrAl single-layer wire mesh, compound the film body on both sides under the action of a rolling force of 30T, and precisely match the rolling speed with the conveyor belt, and prepare the powder mesh composite porous metal film body;

[0042]4. Cut the powder mesh composite porous metal film body into a ...

Embodiment 2

[0046] 1. Prepare PVB isopropanol solution at a mass ratio of 1:20. After aging for 24 hours, stir and mix glycerol and PVB isopropanol solution at a mass ratio of 1:15 to obtain a mixed liquid.

[0047] 2. Mix 316L stainless steel powder with an average particle size of 20 μm and the mixed liquid at a mass ratio of 6:1, slowly add the metal powder, and stir to obtain a viscous slurry system;

[0048] 3. Pour the viscous slurry system into two extruders, and extrude the film body from the slit-shaped die mouth with a size of 800mm×500μm under the push of the screw, and slowly transfer the conveyor belt to the two-roll rolling machine; from the middle top Place a 900mm wide 40-mesh 316L stainless steel single-layer wire mesh, compound the film body on both sides under the action of a rolling force of 100T, and precisely match the rolling speed and the conveyor belt to prepare a powder-mesh composite porous metal film body;

[0049] 4. Cut the powder mesh composite porous metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com