Processing method of crab paste

A processing method and technology for crab paste, which are used in ultra-high pressure food processing, preservation of meat/fish by radiation/electricity treatment, food ingredients as taste improvers, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

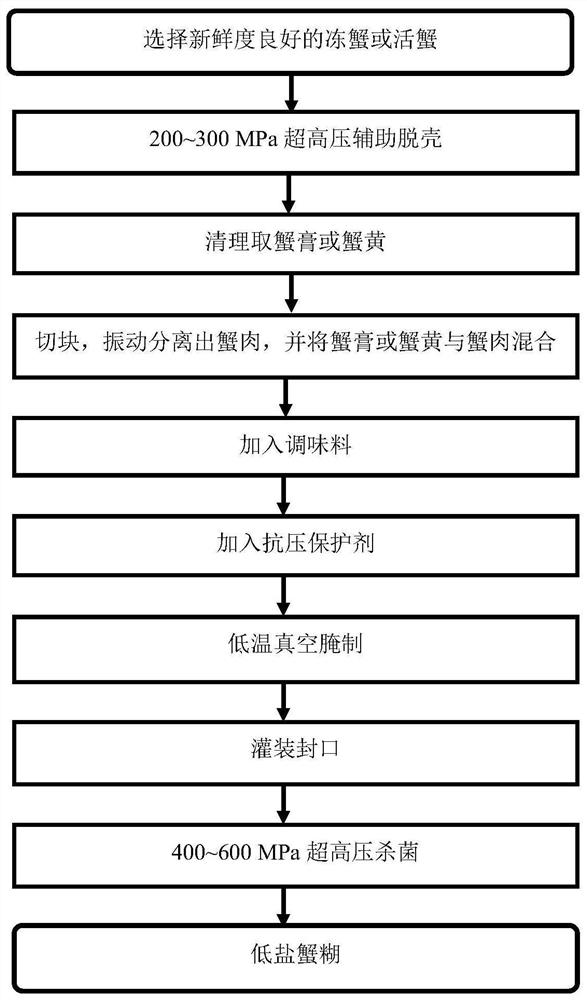

Method used

Image

Examples

Embodiment 1

[0040] (1) Raw material selection: choose crabs with white and clean body, protruding crab navel, reddish color, paste on both ends of the crab, good freshness frozen swimming crabs, and remove the spoiled crabs;

[0041] (2) making crab paste semi-finished product, comprises the following steps:

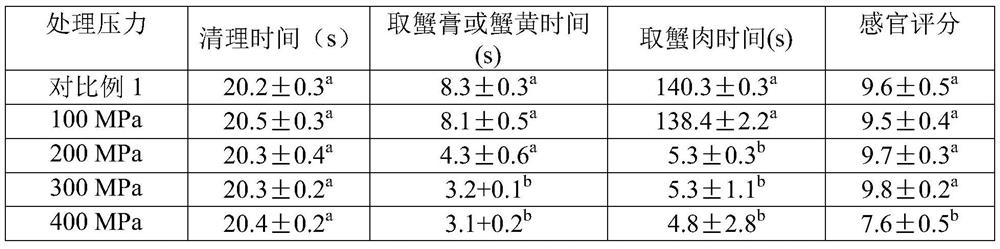

[0042] (2.1) Ultra-high pressure assisted shelling: Take four groups of crabs of the same size, 10 in each group, wash off the surface impurities of the crabs, and then treat the four groups of crabs under ultra-high pressure for 2 minutes at 100MPa, 200MPa, 300MPa, and 400MPa respectively to achieve shelling. The meat is separated, and then the inedible parts of the crab are manually removed (the back shell, crab gills, crab mouth, viscera, crab leg ends and crab navel, squeeze out the crab feces and wash them with water,) and finally take out the crab paste or crab roe to obtain semi-finished crab ;

[0043] (2.2) Use a vibrating sieve to separate the crab shells and crab meat: t...

Embodiment 2

[0057] Steps (1) (2) of this embodiment are the same as the 300MPa ultra-high pressure auxiliary shelling treatment group of embodiment 1, and this embodiment also includes step (3):

[0058] Step (3): Add seasoning to the semi-finished crab paste. The seasoning includes salt, white granulated sugar, monosodium glutamate, white wine and rice wine: divide the semi-finished crab paste into five groups, and the quality of white sugar in each group is 1.5% of that of the semi-finished crab paste. %, the quality of monosodium glutamate is 0.1% of the quality of semi-finished crab paste, the quality of white wine is 0.75% of the quality of semi-finished crab paste, the quality of rice wine is 2.5% of the quality of semi-finished crab paste, and the quality of each group of salt is 0.75% of the quality of semi-finished crab paste. 0%, 1%, 3%, 5%, 7%.

[0059] The following table 2 is the rating result of different salt additions to the taste of crab paste after pickling:

[0060] ...

Embodiment 3

[0063] The steps (1)(2)(3) of this embodiment can refer to embodiment 2, and difference is only that the amount of salt added is 2.0% of the semi-finished product quality of crab paste, other is the same as embodiment 2, and this embodiment also includes step ( 4)(5)(6);

[0064] (4) Add anti-pressure protective agent to the crab paste semi-finished product that adds seasoning, described anti-pressure protective agent comprises ice structural protein, trehalose and baking soda, wherein the addition amount of ice structural protein, trehalose, baking soda is as follows shown;

[0065] L 9 (3 4 ) Orthogonal experimental design sees the following table 3:

[0066]

[0067] Any one of the three factors A, B, and C in Table 3 above can be combined with the other two factors at different levels.

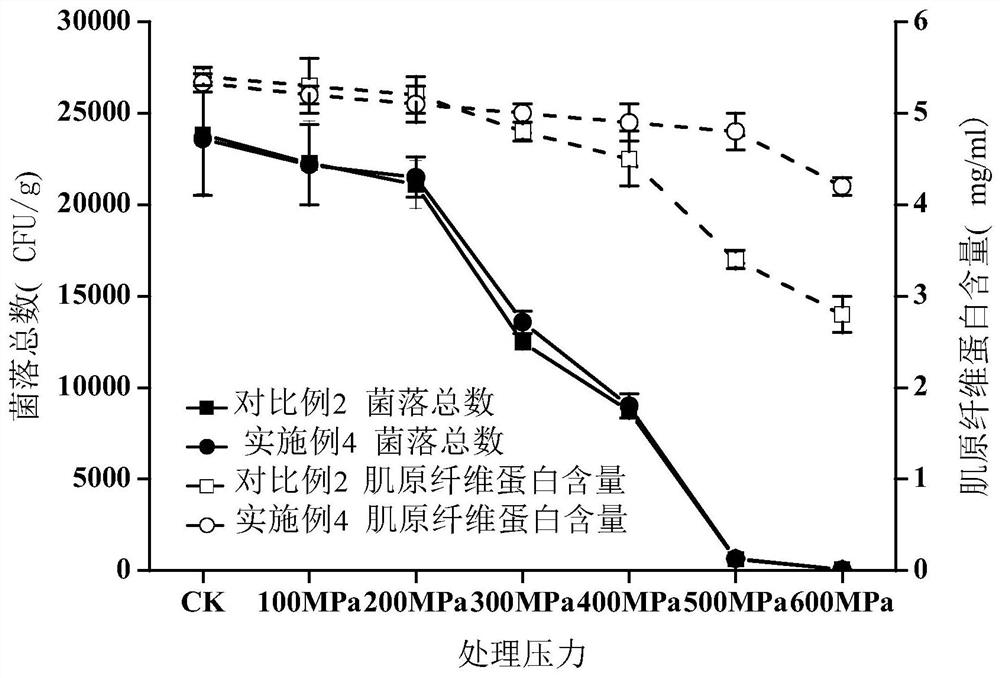

[0068] (5) Pickling the processed crabmeat and crab roe in step (3), the pickling conditions are: temperature is 10°C, vacuum degree-0.01Mpa, pickling for 1h, filling and sealing af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com