Wood structure assembly type self-tapping screw and bolt combined joint

A technology of self-tapping screws and combined joints, which is applied in the direction of building construction and construction, can solve the problems that it cannot be used in the three-dimensional frame of wooden columns, the appearance of components is greatly affected, and it is difficult to apply, so as to achieve simple and effective structure and uniform force , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

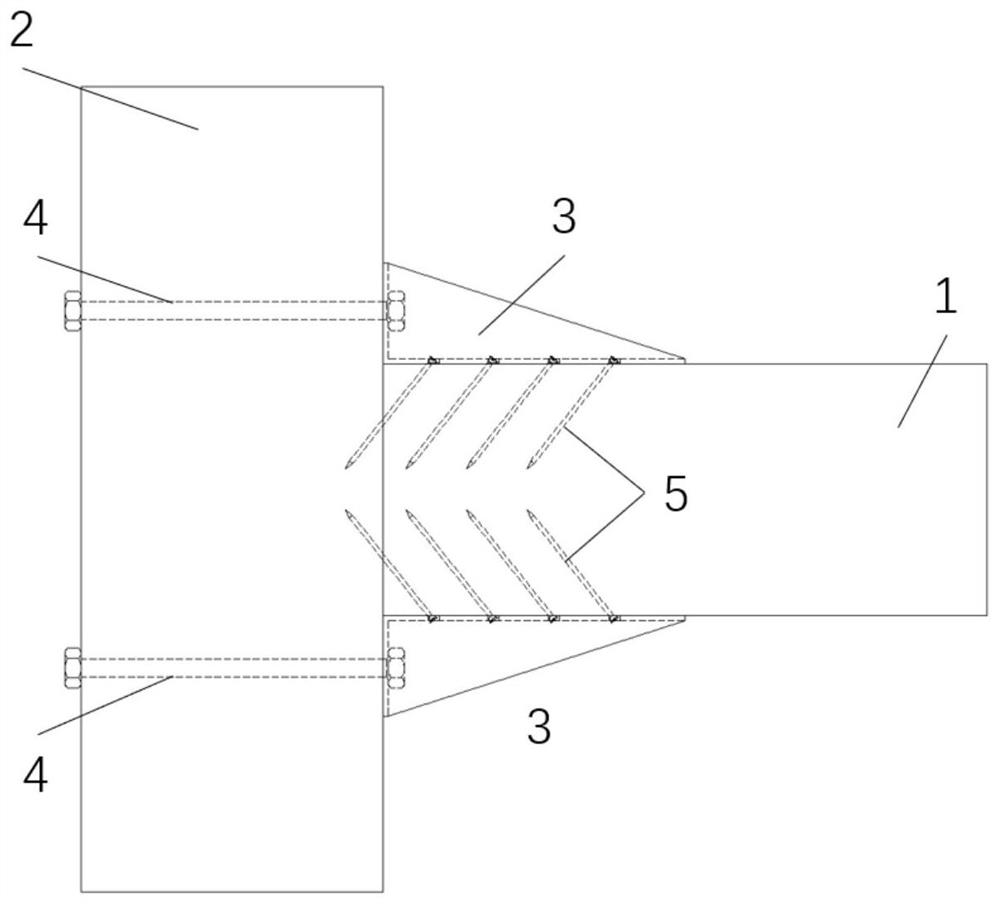

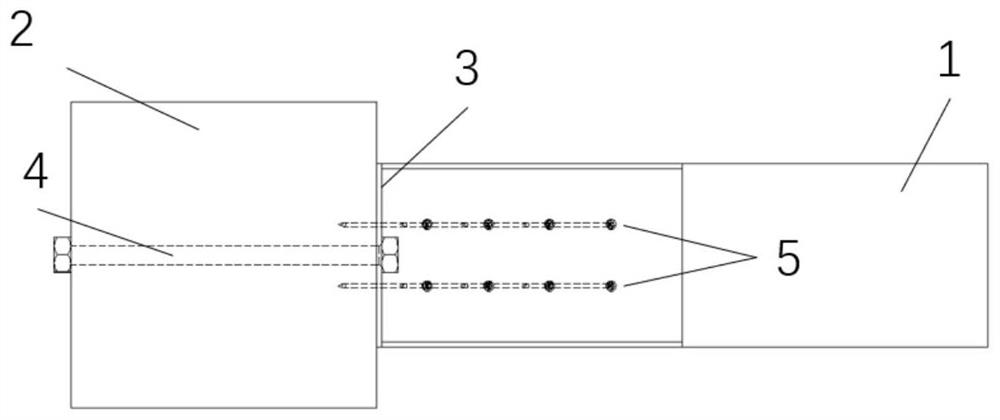

[0038] A wood structure assembled self-tapping screw and bolt combined beam-column joint, its structure is as follows Figure 1 to Figure 6 As shown, it includes a first wooden member 1 and a second wooden member 2 connected to each other, as well as metal connectors 3 , bolts 4 and self-tapping screws 5 for connecting the two members.

[0039] Weld the angle steel with the triangular steel plate to obtain the metal connector 3 , and drill bolt holes 31 and self-tapping screw holes 32 at the corresponding positions of the angle steel to obtain the metal connector 3 .

[0040] Bolt through holes are drilled at the corresponding positions of the node area on the second member 2 .

[0041] The second member 2 is connected to the metal connecting piece 3 through bolts 4, and the bolts 4 are used for shear resistance.

[0042] The first wooden member 1 is connected with the metal connecting piece 3 by self-tapping screws 5 , and the self-tapping screws 5 are inclined to the second...

Embodiment 2

[0045] A wood structure assembled self-tapping screw and bolt combined beam-column joint, its structure is as follows Figure 7 to Figure 11 As shown, it includes a first wooden member 1 connected to each other and a second member 2 composed of a concrete floor, as well as metal connectors 3, bolts 4 and self-tapping screws 5 for connecting the first wooden member 1 and the second member 2 .

[0046] Bolt holes are reserved at corresponding positions in the node area on the second member 2 .

[0047] Through bolts 4, the second member 2 is connected with the metal connector 3 for shear resistance.

[0048] The first wooden member 1 is connected to the metal connecting piece 3 by self-tapping screws 5, and the self-tapping screws 5 are obliquely driven into the second member 2 for bending and pulling resistance.

[0049] On two sides of the first wooden member 1 , metal connectors 3 , bolts 4 and self-tapping screws 5 are arranged symmetrically.

Embodiment 3

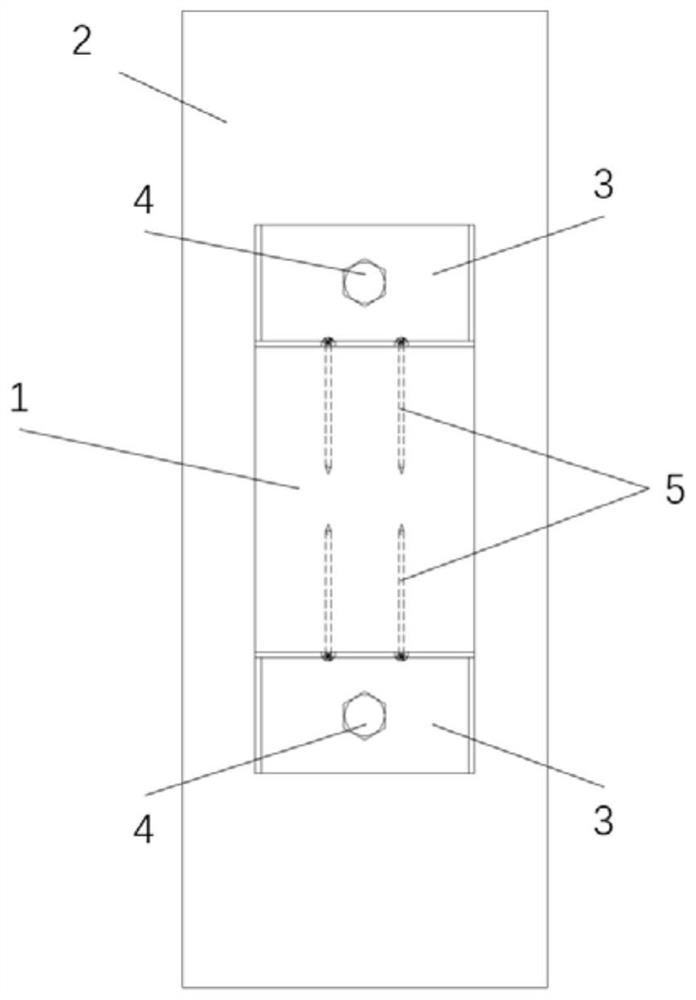

[0051] An assembled self-tapping screw and bolt joint of a wooden structure, including a first wooden member 1 and a second member 2 connected vertically to each other through two metal connectors 3, the first wooden member 1 and the second member 2 are both cuboids The glulam structure, the metal connector 3 is made of vertically welded triangular steel plates on both sides of the angle steel. There are two self-tapping screw holes 32, and the other surface perpendicular to the second member 2 is attached to the second member 2, and a bolt hole 31 is provided on this surface.

[0052] When assembling, the first wooden component 1 and the second component 2 are placed vertically, and the self-tapping screw 5 is obliquely passed through the self-tapping screw hole 32 on the metal connector 3 and driven into the first wooden component 1, and the self-tapping screw 5 faces the second The second member 2 is inclined, and the inclination angle is 45°, and the self-tapping screws 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com