Comprehensive utilization method for bottom-top composite blowing smelting reduction of high-iron red mud

A high-iron red mud and reducing agent technology, applied in cement production, process efficiency improvement, metal processing, etc., can solve the problems of inability to realize large-scale consumption of red mud, inability to directly obtain pig iron products, etc., and achieve high value Use, realize full use, strengthen the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

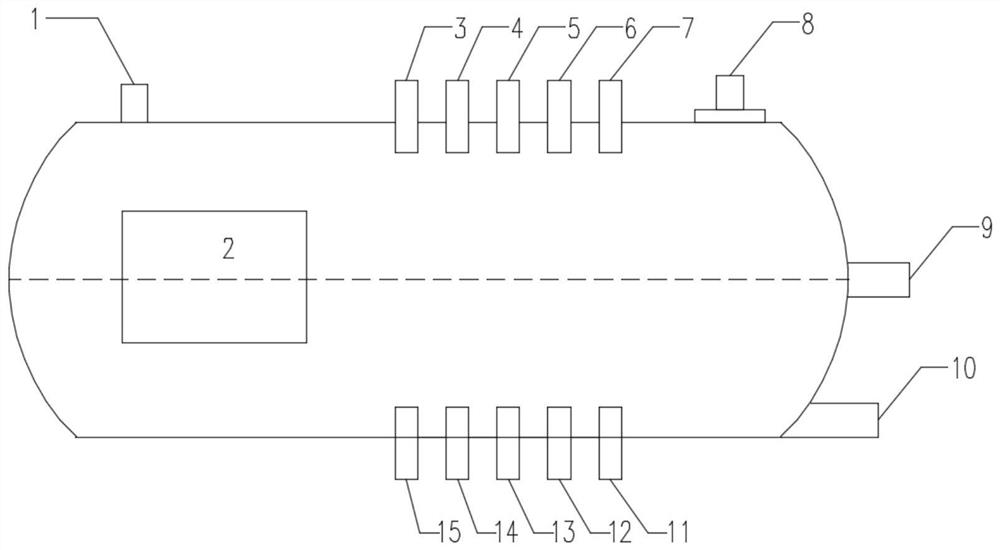

Image

Examples

Embodiment 1

[0034] A method for comprehensive utilization of high-iron red mud by combined bottom-top blowing and smelting reduction, comprising the following steps:

[0035] (1) Mix high-iron red mud with reducing agent, limestone, and fluorite, wherein the reducing agent is coke, and the molar ratio of carbon in the reducing agent to iron oxide in high-iron red mud is 1.5:1; calcium oxide in the added limestone and The ratio of the sum of the mass of silica and alumina in the high-iron red mud is 1.5:1; the amount of fluorite added is 8% of the amount of calcium oxide.

[0036] (2) Add the mixed material from the vortex feed port to the vortex zone in the furnace, and be drawn into the molten pool under the vortex formed by mechanical stirring, and carry out continuous feeding smelting reduction treatment. The reduction process temperature is 1650°C and the time is 30min.

[0037] The reduction process uses CO and O 2 The mixed gas is blown from the bottom of the reduction furnace, in...

Embodiment 2

[0040] A method for comprehensive utilization of high-iron red mud by combined bottom-top blowing and smelting reduction, comprising the following steps:

[0041](1) Mix high-iron red mud with reducing agent, limestone, and fluorite, wherein the reducing agent is pulverized coal, and the molar ratio of carbon in the reducing agent to iron oxide in high-iron red mud is 6.5:1; calcium oxide in the added limestone The ratio to the sum of the mass of silica and alumina in high-iron red mud is 0.8:1; the amount of fluorite added is 15% of the amount of calcium oxide added.

[0042] (2) Add the mixed material from the vortex feed port to the vortex zone in the furnace, and be drawn into the molten pool under the vortex formed by mechanical stirring, and carry out continuous feeding smelting reduction treatment. The reduction process temperature is 1450°C and the time is 140min.

[0043] The reduction process uses CO and O 2 The mixed gas is blown from the bottom of the reduction f...

Embodiment 3

[0046] A method for comprehensive utilization of high-iron red mud by combined bottom-top blowing and smelting reduction, comprising the following steps:

[0047] (1) Mix high-iron red mud with reducing agent, limestone, and fluorite, wherein the reducing agent is a spent cathode carbon block, and the molar ratio of carbon in the reducing agent to iron oxide in high-iron red mud is 4:1; the added limestone The ratio of calcium oxide to the sum of the mass of silica and alumina in high iron red mud is 1:1; the amount of fluorite added is 10% of the amount of calcium oxide.

[0048] (2) Add the mixed material from the vortex feed port to the vortex zone in the furnace, and be drawn into the molten pool under the vortex formed by mechanical stirring, and carry out continuous feeding smelting reduction treatment. The temperature of the reduction process is 1500° C., and the time is 60 minutes.

[0049] The reduction process uses CH 4 with O 2 The mixed gas is blown from the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com