Hyperbranched polymer for efficiently recovering boron and ultrafiltration process thereof

A technology of hyperbranched polymer and hyperbranched polymer, applied in ultrafiltration, water pollutants, chemical instruments and methods, etc., can solve the problems of low kinetics, low boron, interception, etc., and achieve the effect of improving interception efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

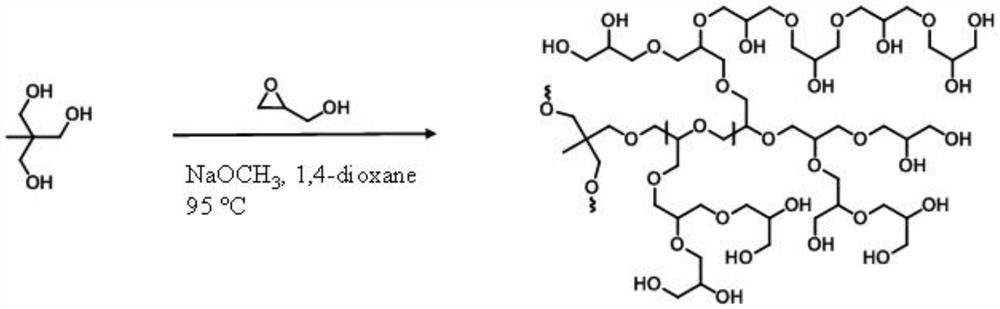

[0030] The preparation method of hyperbranched polyglycidol (HPG), comprises the following steps,

[0031] A1: Combine 1.5 mmol pentaerythritol (THME) and 0.5 mmol NaOCH 3 Dissolve in 100 mL of methanol to obtain a mixture;

[0032] A2: Heat the mixture obtained from A1 to 75±1°C, then keep the temperature under vacuum for 4 hours to remove methanol and water, and generate sodium alkoxide;

[0033] A3: After the sodium alkoxide obtained in A2 is cooled, mix 1,4-dioxane with the cooled sodium alkoxide, and perform ultrasonic treatment for 20 minutes to obtain a uniform solution;

[0034] A4: The homogeneous solution obtained in A3 was continuously bubbled with argon for 10 minutes to remove dissolved oxygen, and the solution was kept in an inert atmosphere, then, the solution was stirred and heated to 95±1°C, and then at this temperature by automatic feeding The sampler slowly injected 150 mmol of argon-purified glycidol into the solution at a rate of 1.8 ml / h. After the glyc...

Embodiment 2

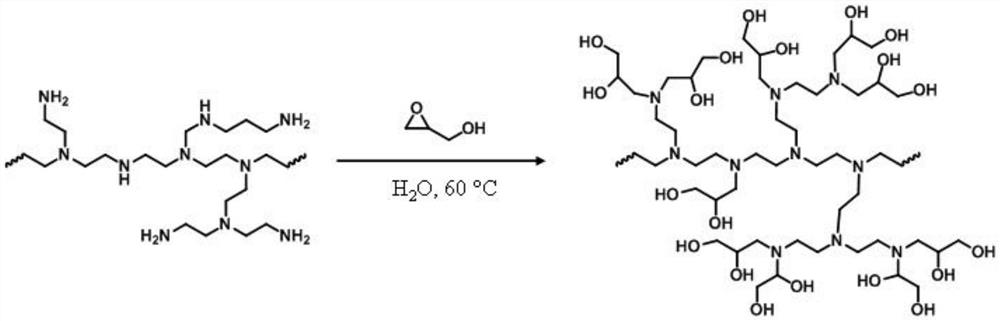

[0039] The preparation method of Diol-HPEI polymer comprises the following steps,

[0040] B1: 20 g of an aqueous hyperbranched polyethyleneimine (HPEI) solution was diluted with deionized water to a solids concentration of 10 wt% at room temperature and purged with argon for 10 minutes;

[0041] B2: At room temperature, 40 g of glycidol was slowly added to the hyperbranched polyethyleneimine (HPEI) solution within 20 minutes. After the addition, the solution was stirred at room temperature for 3 hours, and then heated in a water bath at 60°C for 3 hours. Hour;

[0042] B3: After B2 is heated, it is cooled at room temperature, and the cooled solution is purified by dialysis with a membrane tube with a MWCO range of 6000-8000 for 3 days;

[0043] B4: The purified solution was concentrated by vacuum distillation in a rotary evaporator to obtain a viscous solution, and the concentrated solution was lyophilized overnight to obtain the Diol-HPEI polymer.

[0044]The chemical form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com