Anaerobic-anoxic-aerobiotic-aerobiotic-membrane component treatment method

A treatment method and membrane module technology, applied in aerobic and anaerobic process treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem of the increase of suspended solids in the effluent of the system, the influence of the natural sedimentation of sludge, and the increase of suspended solids in the effluent. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Implement this patent at the sewage treatment construction site.

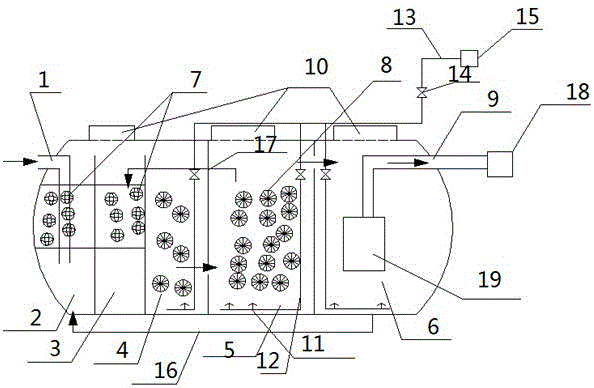

[0029] A2O2+MBR treatment device includes: water inlet 1, anaerobic pool 2, anoxic pool 3, micro-aerobic pool 4, aerobic pool 5, membrane pool 6, spherical packing 7, MBBR packing 8, MBR membrane module 19, outlet pipe 9. Inspection port 10, aeration device, sludge return pipe 16, nitrification liquid return pipe 17, self-priming pump 18; aeration device refers to aeration head 11, aeration branch pipe 12, aeration main pipe 12, gas regulating valve 14. Aeration equipment 15; a biological filter bed is installed in the anaerobic tank 2 and the anoxic tank 3, and a spherical filler 7 is placed in the biological filter bed, and the spherical filler 7 in the biological filter bed is fixed; MBBR filler 8 is placed in pool 4 and aerobic pool 5, and MBBR filler 8 is removable; MBR membrane module 19 is installed in membrane pool 6; The tops of the aerobic pool 5 and the membrane pool 6 are equipped with an in...

Embodiment 2

[0046] The upper filter plate of the biological filter bed is 98mm from the lower end of the outlet pipe, and the lower filter plate of the biological filter bed is 385mm from the bottom.

[0047] The rest are the same as above and will not be repeated.

Embodiment 3

[0049] The upper filter plate of the biological filter bed is 168mm from the lower end of the outlet pipe, and the lower filter plate of the biological filter bed is 428mm from the bottom.

[0050] The rest are the same as above and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com