Non-valve filter with double filter layers

A valveless filter, double filter layer technology, applied in the field of water treatment, can solve the problems of short replacement cycle, difficult to meet the effluent, sand running, etc., to achieve the effect of improving effluent quality, high interception efficiency and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

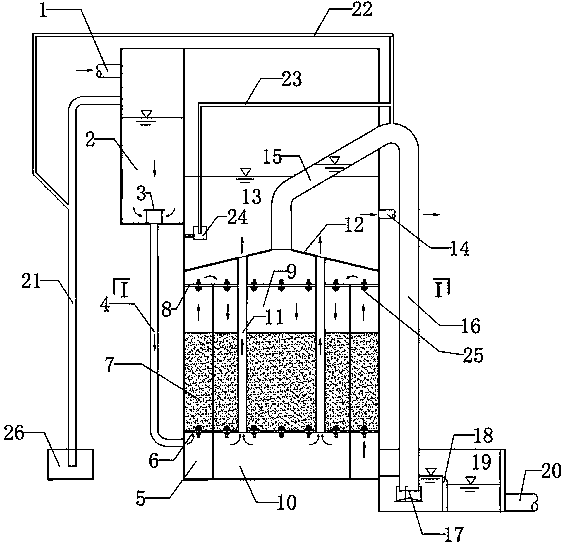

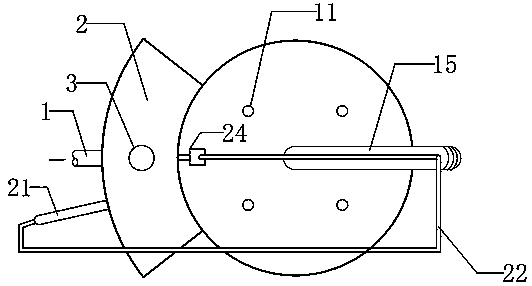

[0020] Such as Figure 1-Figure 3 As shown, the double filter layer valveless filter is composed of water inlet pipe, filter unit and siphon system. Its structure is as follows: figure 1 shown. in:

[0021] The water inlet part is composed of water inlet pipe 1, water distribution tank 2, baffle plate 3, and water inlet branch pipe 4. Two devices can share one water inlet pipe 1, and a baffle plate 3 is provided at the water inlet branch pipe port 4; the function of the baffle plate 3 is to prevent The gas enters the subsequent section.

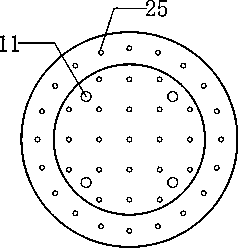

[0022] The filter unit is a double-layer cylindrical filter tank, which consists of the first water distribution chamber 5, the lower filter plate 6, the ceramsite filter material 7, the upper filter plate 8, the second water distribution chamber 9, the clean water chamber 10, the clean water pipe 11, The filter head 25, the water outlet 14, and the flushing water tank 13 are composed of the homogeneous ceramsite filter material above the ...

Embodiment 2

[0030] Example 2: The raw water is river water in a certain village, and the treatment scale is 100m 3 / d, the front end adopts "grid flocculation + inclined tube precipitation", and the present invention is adopted later, the raw water turbidity is 35NTU, the dosage of polyaluminum chloride is 20mg / L, and the turbidity of the precipitated water is 4NTU, after being filtered by the present invention , The turbidity of the effluent is 0.7NTU.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com